Installation instructions

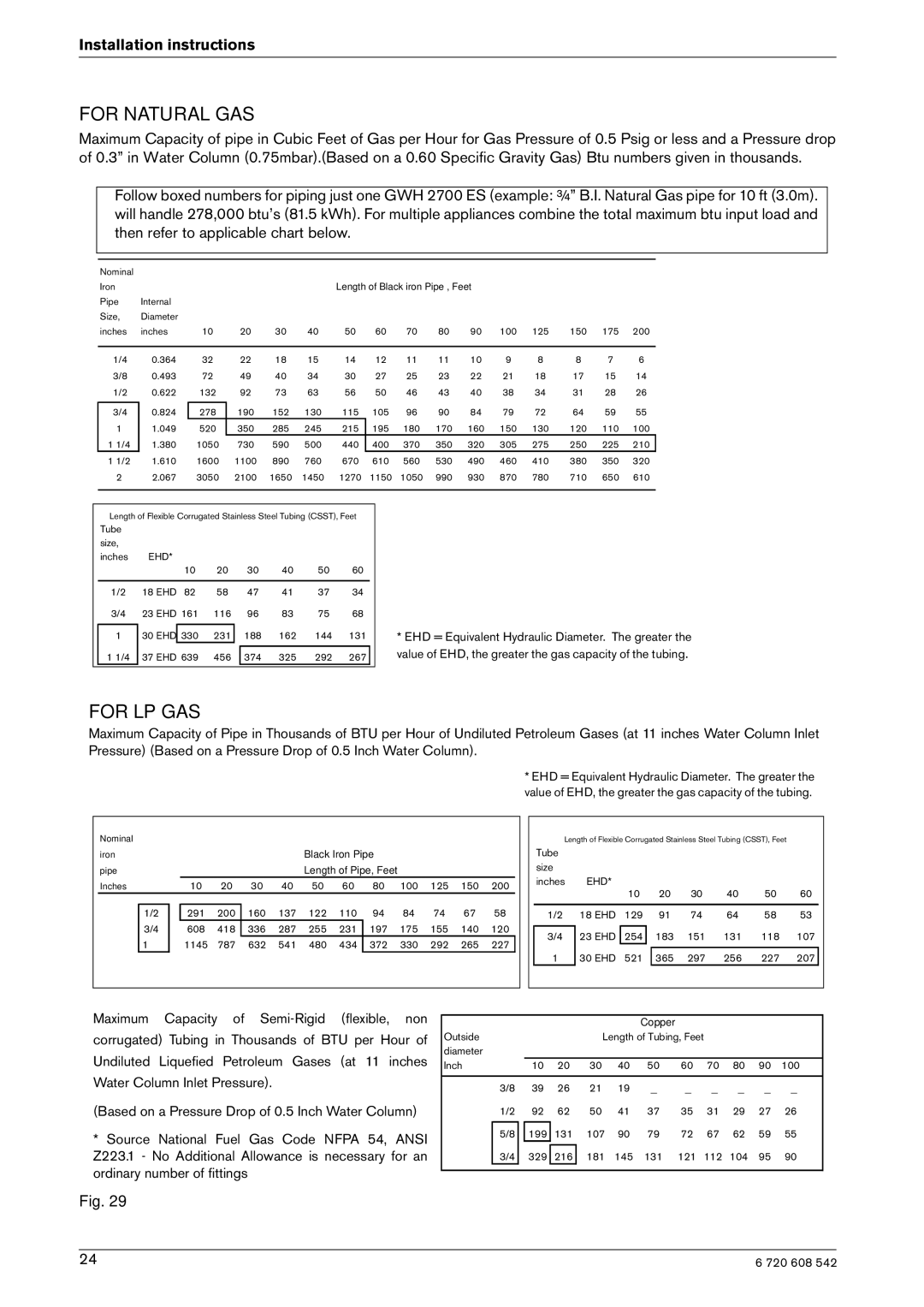

FOR NATURAL GAS

Maximum Capacity of pipe in Cubic Feet of Gas per Hour for Gas Pressure of 0.5 Psig or less and a Pressure drop of 0.3” in Water Column (0.75mbar).(Based on a 0.60 Specific Gravity Gas) Btu numbers given in thousands.

Follow boxed numbers for piping just one GWH 2700 ES (example: ¾” B.I. Natural Gas pipe for 10 ft (3.0m). will handle 278,000 btu’s (81.5 kWh). For multiple appliances combine the total maximum btu input load and then refer to applicable chart below.

Nominal |

|

|

|

|

|

|

|

|

|

|

|

|

Iron |

|

|

|

|

| Length of Black iron Pipe , Feet |

|

| ||||

Pipe | Internal |

|

|

|

|

|

|

|

|

|

|

|

Size, | Diameter |

|

|

|

|

|

|

|

|

|

|

|

inches | inches | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 125 | 150 175 200 |

1/4

3/8

1/2

3/4

1

11/4

11/2

2

0.364

0.493

0.622

0.824

1.049

1.380

1.610

2.067

32 | 22 | 18 | 15 | 14 | 12 | 11 | 11 | 10 | 9 | 8 | 8 | 7 | 6 |

72 | 49 | 40 | 34 | 30 | 27 | 25 | 23 | 22 | 21 | 18 | 17 | 15 | 14 |

132 | 92 | 73 | 63 | 56 | 50 | 46 | 43 | 40 | 38 | 34 | 31 | 28 | 26 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

278 | 190 | 152 | 130 | 115 | 105 | 96 | 90 | 84 | 79 | 72 | 64 | 59 | 55 |

520 | 350 | 285 | 245 | 215 | 195 | 180 | 170 | 160 | 150 | 130 | 120 | 110 | 100 |

1050 | 730 | 590 | 500 | 440 | 400 | 370 | 350 | 320 | 305 | 275 | 250 | 225 | 210 |

1600 | 1100 | 890 | 760 | 670 | 610 | 560 | 530 | 490 | 460 | 410 | 380 | 350 | 320 |

3050 | 2100 | 1650 | 1450 | 1270 | 1150 | 1050 | 990 | 930 | 870 | 780 | 710 | 650 | 610 |

Length of Flexible Corrugated Stainless Steel Tubing (CSST), Feet

Tube |

|

|

|

|

|

|

|

|

size, |

|

|

|

|

|

|

|

|

inches | EHD* |

|

|

|

|

|

| |

| 10 | 20 | 30 | 40 | 50 | 60 | ||

|

|

|

|

|

|

| ||

1/2 | 18 EHD 82 | 58 | 47 | 41 | 37 | 34 | ||

3/4 | 23 EHD 161 | 116 | 96 | 83 | 75 | 68 | ||

|

|

|

|

|

|

|

|

|

1 | 30 EHD | 330 | 231 | 188 | 162 | 144 | 131 | |

|

|

|

|

|

|

|

| |

1 1/4 | 37 EHD 639 | 456 |

| 374 | 325 | 292 | 267 | |

*EHD = Equivalent Hydraulic Diameter. The greater the value of EHD, the greater the gas capacity of the tubing.

FOR LP GAS

Maximum Capacity of Pipe in Thousands of BTU per Hour of Undiluted Petroleum Gases (at 11 inches Water Column Inlet Pressure) (Based on a Pressure Drop of 0.5 Inch Water Column).

* EHD = Equivalent Hydraulic Diameter. The greater the value of EHD, the greater the gas capacity of the tubing.

Nominal |

|

|

|

|

|

|

|

|

|

|

|

|

| |

iron |

|

|

|

|

|

| Black Iron Pipe |

|

|

|

| |||

pipe |

|

|

|

|

|

| Length of Pipe, Feet |

|

|

|

| |||

Inches | 10 | 20 | 30 | 40 | 50 | 60 | 80 | 100 | 125 | 150 | 200 | |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 1/2 |

| 291 | 200 | 160 | 137 | 122 | 110 | 94 | 84 | 74 | 67 | 58 | |

| 3/4 | 608 | 418 | 336 | 287 | 255 | 231 | 197 | 175 | 155 | 140 | 120 | ||

| 1 | 1145 | 787 | 632 | 541 | 480 | 434 | 372 | 330 | 292 | 265 | 227 | ||

Length of Flexible Corrugated Stainless Steel Tubing (CSST), Feet

Tube |

|

|

|

|

|

|

|

|

size |

|

|

|

|

|

|

|

|

inches | EHD* |

|

|

|

|

|

|

|

|

| 10 | 20 | 30 | 40 | 50 | 60 | |

|

|

|

|

|

|

|

| |

1/2 | 18 EHD | 129 | 91 | 74 | 64 | 58 | 53 | |

|

|

|

|

|

|

|

|

|

3/4 | 23 EHD | 254 | 183 | 151 | 131 | 118 | 107 | |

|

|

|

|

|

|

|

|

|

1 | 30 EHD | 521 |

| 365 | 297 | 256 | 227 | 207 |

Maximum Capacity of

Undiluted Liquefied Petroleum Gases (at 11 inches Water Column Inlet Pressure).

(Based on a Pressure Drop of 0.5 Inch Water Column)

*Source National Fuel Gas Code NFPA 54, ANSI Z223.1 - No Additional Allowance is necessary for an ordinary number of fittings

|

|

|

|

|

|

| Copper |

|

|

|

|

|

Outside |

|

|

| Length of Tubing, Feet |

|

|

| |||||

diameter |

|

|

|

|

|

|

|

|

|

|

| |

Inch | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 90 | 100 | ||

|

|

|

|

|

|

|

|

|

|

| ||

3/8 | 39 | 26 | 21 | 19 | _ | _ | _ | _ | _ | _ | ||

1/2 | 92 | 62 | 50 | 41 | 37 | 35 | 31 | 29 | 27 | 26 | ||

|

|

|

|

|

|

|

|

|

|

|

|

|

| 5/8 |

| 199 | 131 | 107 | 90 | 79 | 72 | 67 | 62 | 59 | 55 |

|

|

|

|

|

|

|

|

|

|

|

|

|

| 3/4 | 329 | 216 | 181 | 145 | 131 | 121 | 112 | 104 | 95 | 90 | |

|

|

|

|

|

|

|

|

|

|

|

|

|

Fig. 29

24 | 6 720 608 542 |