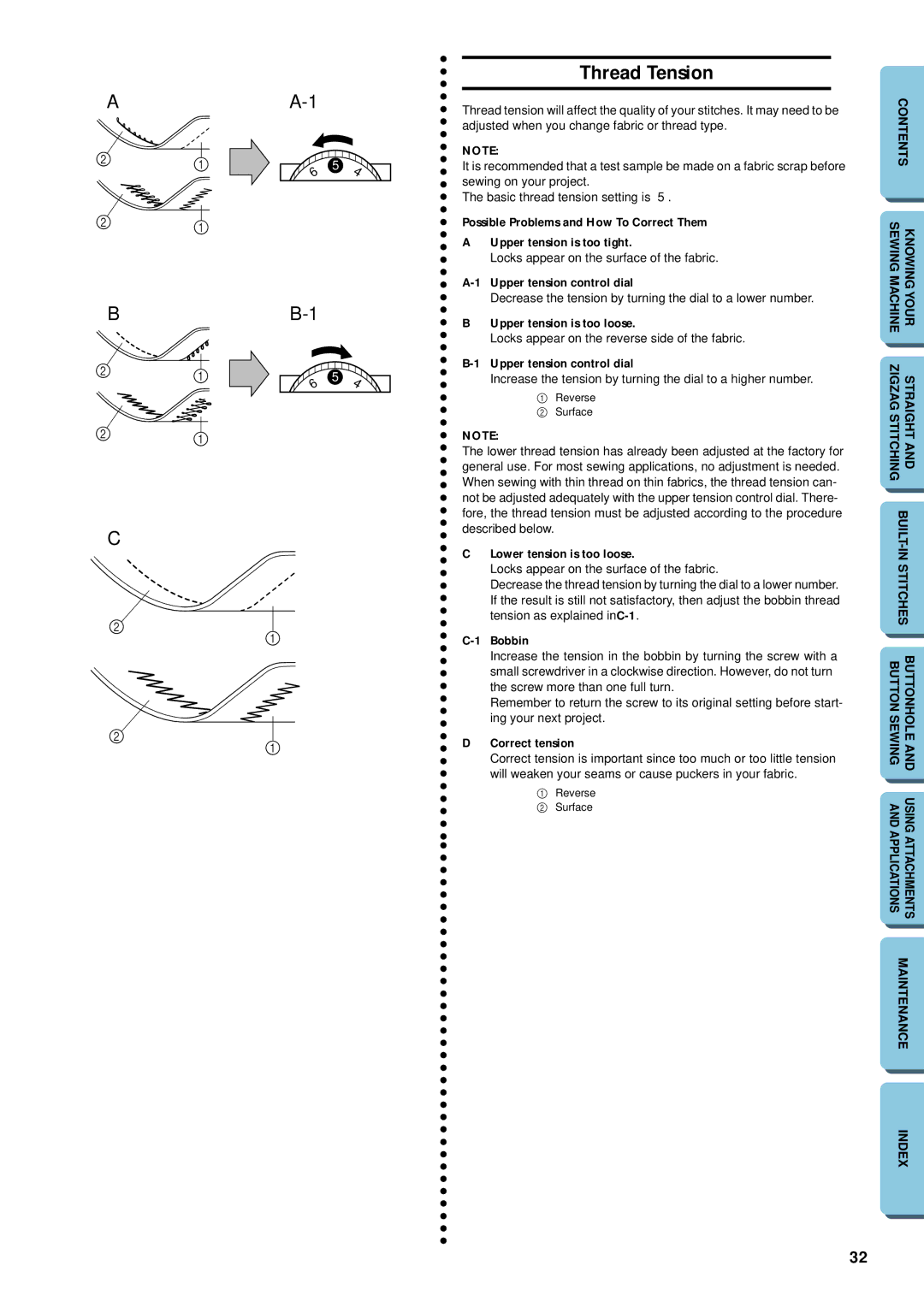

A

21

21

B

21

21

6 | 5 | 4 |

|

6 | 5 | 4 |

|

Thread Tension

Thread tension will affect the quality of your stitches. It may need to be adjusted when you change fabric or thread type.

NOTE:

It is recommended that a test sample be made on a fabric scrap before sewing on your project.

The basic thread tension setting is “5”.

Possible Problems and How To Correct Them

AUpper tension is too tight.

Locks appear on the surface of the fabric.

Decrease the tension by turning the dial to a lower number.

BUpper tension is too loose.

Locks appear on the reverse side of the fabric.

Increase the tension by turning the dial to a higher number.

1Reverse

2 Surface

NOTE:

C

2

2

1

1

The lower thread tension has already been adjusted at the factory for general use. For most sewing applications, no adjustment is needed. When sewing with thin thread on thin fabrics, the thread tension can- not be adjusted adequately with the upper tension control dial. There- fore, the thread tension must be adjusted according to the procedure described below.

CLower tension is too loose.

Locks appear on the surface of the fabric.

Decrease the thread tension by turning the dial to a lower number. If the result is still not satisfactory, then adjust the bobbin thread tension as explained in

C-1 Bobbin

Increase the tension in the bobbin by turning the screw with a small screwdriver in a clockwise direction. However, do not turn the screw more than one full turn.

Remember to return the screw to its original setting before start- ing your next project.

DCorrect tension

Correct tension is important since too much or too little tension will weaken your seams or cause puckers in your fabric.

1Reverse

2 Surface

STITCHING | AND |

BUTTON SEWING | BUTTONHOLE AND |

AND APPLICATIONS | USING ATTACHMENTS |

MAINTENANCE | |

INDEX

32