580J*04--12 specifications

The Bryant 580J*04--12 is a notable unit in the realm of residential air conditioning, exemplifying efficiency and reliability. Designed to offer optimal cooling solutions, this model incorporates advanced technologies and features that cater to modern comfort needs.One of the standout features of the Bryant 580J is its energy efficiency. With a high Seasonal Energy Efficiency Ratio (SEER) rating, this air conditioning unit is engineered to minimize energy consumption while maximizing cooling performance. This efficiency not only reduces monthly utility bills but also aligns with environmentally friendly practices by using less energy.

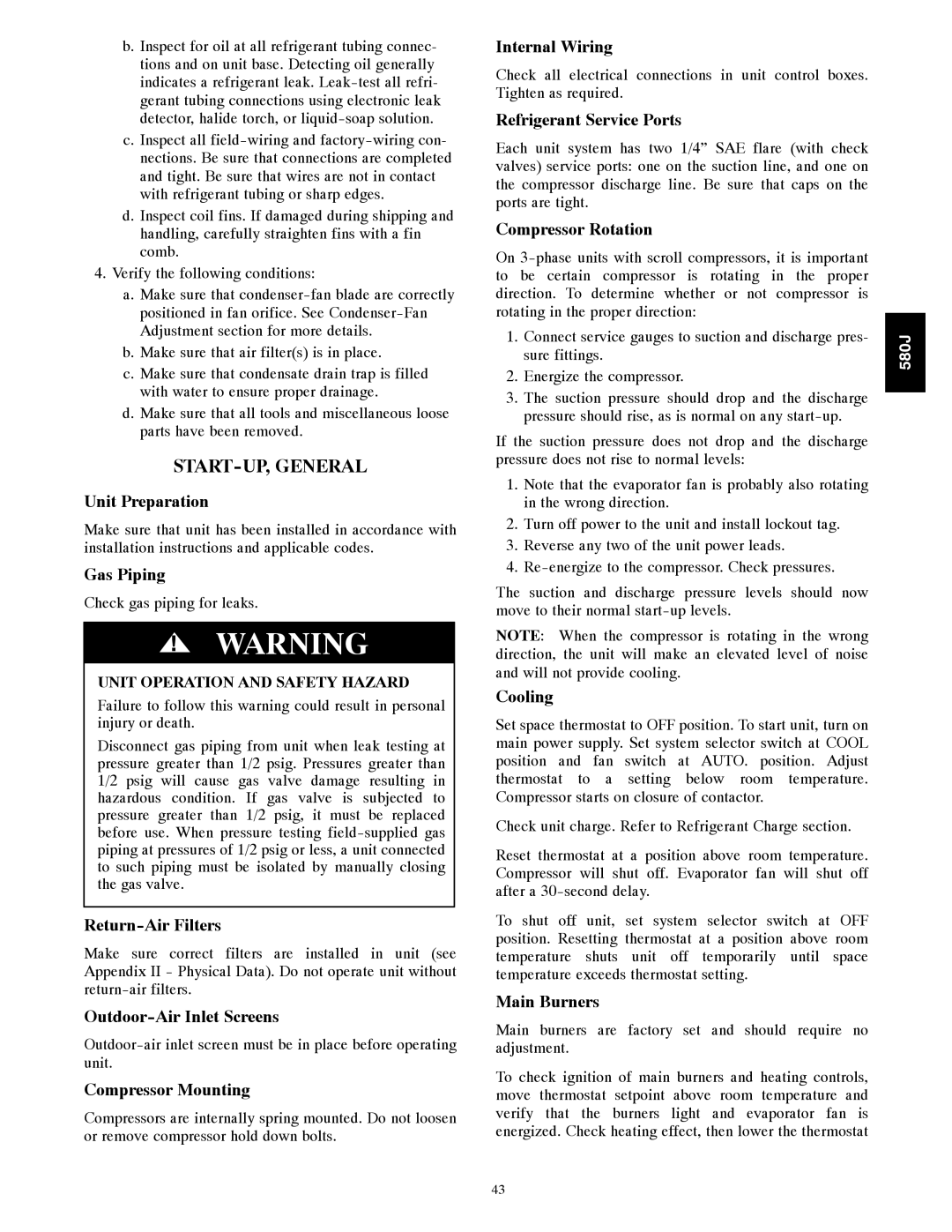

The 580J model is equipped with advanced compressor technology, which contributes to its smooth and quiet operation. This is particularly important for residential settings, where noise can be a significant concern. The unit consistently maintains comfortable indoor temperatures without disruptive sound levels, enhancing the overall living experience.

This air conditioning system is designed with durability in mind. Constructed from robust materials, it withstands the rigors of various weather conditions. Additionally, its components are engineered for longevity, reducing the need for frequent repairs and maintenance. The 580J also comes with a comprehensive warranty, which provides homeowners with peace of mind regarding their investment.

Smart technology integration is another key feature of the Bryant 580J. Homeowners can take advantage of programmable thermostats and compatibility with home automation systems. This allows for remote access and control, making it easier to manage indoor climates efficiently. Users can set schedules, adjust temperatures, and monitor energy usage from their smartphones, adding a layer of convenience to everyday living.

Furthermore, the Bryant 580J includes advanced air filtration systems that improve indoor air quality. By effectively trapping dust, allergens, and pollutants, this unit promotes a healthier living environment. This feature is particularly beneficial for individuals with allergies or respiratory issues.

In summary, the Bryant 580J*04--12 stands out for its energy efficiency, quiet operation, durability, smart technology integration, and air quality improvement capabilities. By blending advanced engineering with user-friendly features, this model continues to be a top choice for homeowners seeking reliable and efficient air conditioning solutions.