TABLE OF CONTENTS

SAFETY CONSIDERATIONS

FIRE, EXPLOSION HAZARD

What to do if you smell gas

UNIT ARRANGEMENT AND ACCESS

Routine Maintenance

Seasonal Maintenance

UNIT OPERATION AND SAFETY HAZARD

Fig. 3 - Filter Installation

Fig. 4 - Screens Installed on Outdoor-AirHood

Heating

Economizer or Outside Air Damper

Adjustable-PitchPulley on Motor

SUPPLY FAN BLOWER SECTION

Supply Fan Belt-Drive

ELECTRICAL SHOCK HAZARD

Fig. 6 - Supply-FanPulley Adjustment Bearings

COOLING

Condenser Coil

Fig. 7 - Tightening Locking Collar Motor

Periodic Clean Water Rinse

Routine Cleaning of Coil Surfaces

Fig. 8 - Cleaning Condenser Coil

One-RowCoil

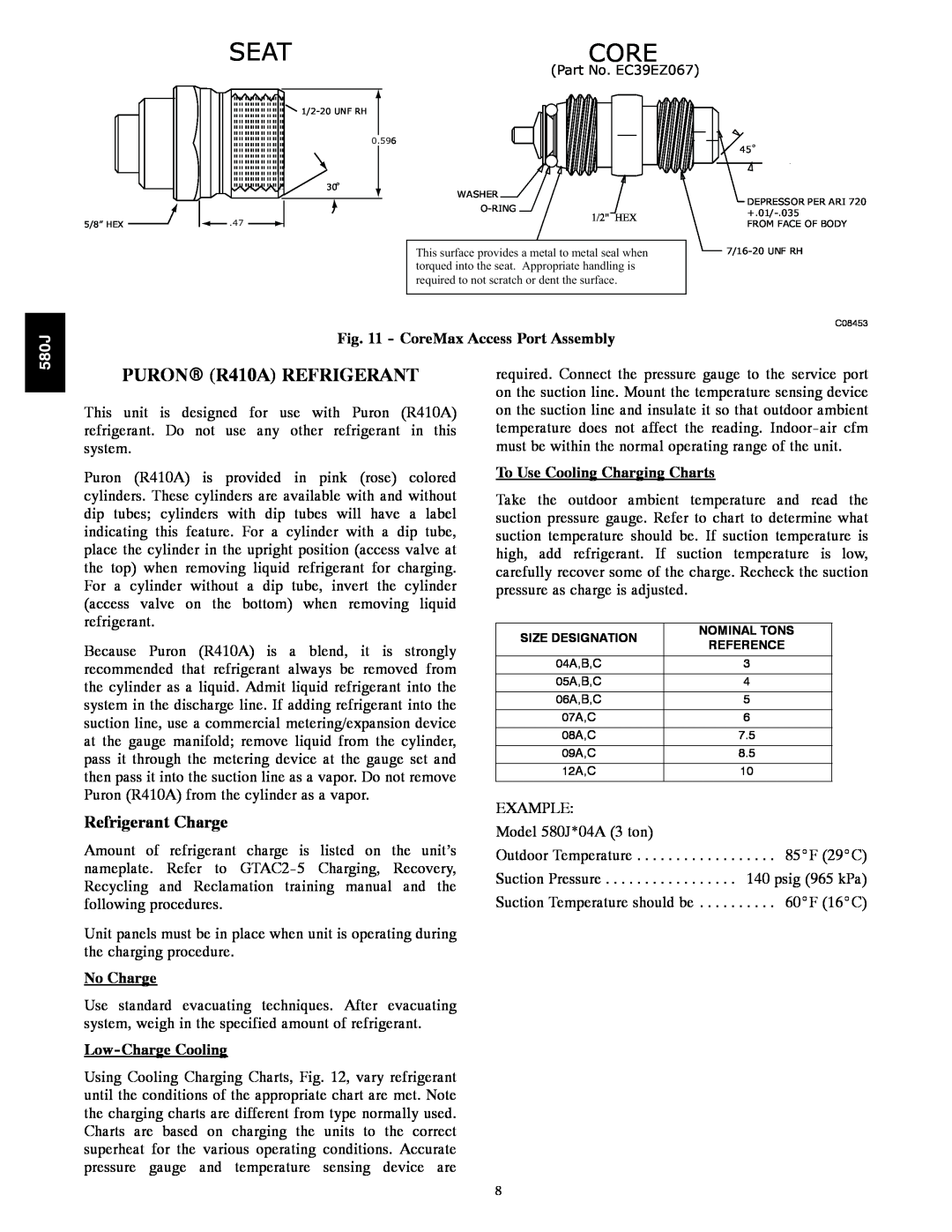

Refrigerant System Pressure Access Ports

Cleaning the Evaporator Coil

Evaporator Coil

UNIT DAMAGE HAZARD

Fig. 11 - CoreMax Access Port Assembly

To Use Cooling Charging Charts

PURONR R410A REFRIGERANT

Refrigerant Charge

COOLING CHARGING CHARTS

Fig. 12 - Cooling Charging Charts

580J

C08203 C08204

COOLING CHARGING CHARTS cont

Fig. 12 - Cooling Charging Charts cont

580J

C08228 C08229

COOLING CHARGING CHARTS cont

Fig. 12 - Cooling Charging Charts cont

580J

C08437 C08438

COOLING CHARGING CHARTS cont

Fig. 12 - Cooling Charging Charts cont

580J

C08439

Troubleshooting Cooling System

Fig. 13 - Condenser Fan Adjustment

Compressor

Filter Drier

Table 1 – Cooling Service Analysis

580J

Fig. 15 - Powered Convenience Outlet Wiring

CONVENIENCE OUTLETS

Fig. 14 - Convenience Outlet Location

ELECTRICAL OPERATION HAZARD

Fig. 16 - Controller Assembly

SMOKE DETECTORS

System

Sensor

Smoke Detector Locations

Location

Fig. 19 - Typical Return Air Detector Location

Fig. 20 - Return Air Sampling Tube Location

FIOP Smoke Detector Wiring and Response

Fig. 23 - Typical Smoke Detector System Wiring

Fig. 22 - Return Air Sensor Operating Position

B C D A

Sensor Alarm Test

Controller Alarm Test

Sensor Alarm Test Procedure

Controller Alarm Test Procedure

Remote Test/Reset Station Dirty Sensor Test

Detector Cleaning

To Configure the Dirty Sensor Test Operation

SD-TRK4Remote Alarm Test Procedure

Indicators

Table 3 – Detector Indicators

Alarm State

Fig. 25 - Sensor Cleaning Diagram

Troubleshooting

Resetting Alarm and Trouble Condition Trips

Sensor’s Power LED is Off

Controller’s Power LED is Off

Fig. 28 - Limit Switch Location

GAS HEATING SYSTEM

Control Circuit,

Fuel Types and Pressures

Fig. 29 - LP Low Pressure Switch Installed

Flue Gas Passageways

Combustion-AirBlower

Table 7 – Liquid Propane Manifold Pressure Ranges

Fig. 31 - Heat Exchanger Assembly

Removal and Replacement of Gas Train

Cleaning and Adjustment

Burners and Igniters

Limit Switch

Burner Ignition

Fig. 34 - Unit Control Box/IGC Location

580J

Fig. 35 - Spark Adjustment,

Fig. 36 - Spark Adjustment,

580J

C06154

Orifice Replacement

Table 8 – LED Error Code Description

Fig. 37 - Gas Valves

Single Stage

Fig. 38 - Integrated Gas Control IGC Board

Table 9 – IGC Connections

Red LED-Status

580J

Table 10 – Orifice Sizes

580J

Troubleshooting Heating System

Minimum heating entering air temperature

Table 11 cont. - Altitude Compensation* A08-A12

580J

Table 13 – Heating Service Analysis

PROBLEM

580J

CAUSE

Table 14 – IGC Board LED Alarm Codes

ECONOMIZER SYSTEMS

Fig. 39 - EconoMi$er IV Component Locations

580J

Fig. 41 - EconoMi$er IV Wiring

Fig. 40 - EconoMi$er2 Component Locations

580J

C06022

Table 15 – EconoMi$er IV Input/Output Logic

580J

Outdoor Air Temperature OAT Sensor

Supply Air Temperature SAT Sensor

EconoMi$er

Fig. 43 - EconoMi$er IV Functional View

Fig. 46 - Outside Air Temperature Changeover

Fig. 44 - Supply Air Sensor Location

Outdoor Air Lockout Sensor

EconoMi$er IV Control Modes

Differential Enthalpy Control

Mounting Location

Outdoor Enthalpy Changeover

Fig. 49 - Enthalpy Changeover Setpoints

Fig. 51 - CO2 Sensor Maximum Range Settings

Exhaust Setpoint Adjustment

Fig. 50 - EonoMi$er IV Control

Indoor Air Quality IAQ Sensor Input

CO2 Sensor Configuration

Damper Movement

Thermostats

Occupancy Control

Table 17 – EconoMi$er IV Sensor Usage

EconoMi$er IV Preparation

Differential Enthalpy

Single Enthalpy

WIRING DIAGRAMS

EconoMi$er IV Troubleshooting Completion

PRE-START-UP

DCV Minimum and Maximum Position

Internal Wiring

Refrigerant Service Ports

START-UP,GENERAL

Unit Preparation

OPERATING SEQUENCES

Heating

Ventilation Continuous Fan

Cooling, Unit Without Economizer

FASTENER TORQUE VALUES

Demand Controlled Ventilation

Heating With EconoMi$er

Table 18 – Torque Values

580J

C08308

580J

C08317

APPENDIX I. MODEL NUMBER SIGNIFICANCE

Model Number Nomenclature

Serial Number Format

580J

APPENDIX II. PHYSICAL DATA

Physical Data Cooling

3 - 6 TONS - Standard Refrigeration System

580J

APPENDIX II. PHYSICAL DATA cont

7.5 - 10 TONS - Standard Refrigeration System

Physical Data Cooling

580J

Physical Data Heating

3 - 6 TONS

APPENDIX II. PHYSICAL DATA cont

580J

7.5 - 10 TONS

APPENDIX II. PHYSICAL DATA cont

Physical Data Heating

580J

580J

APPENDIX III. FAN PERFORMANCE

General Fan Performance Notes

1 Phase

APPENDIX III. FAN PERFORMANCE cont

580J*04

3 Ton Horizontal Supply

3 Phase

3 Phase

APPENDIX III. FAN PERFORMANCE cont

580J*04

1 Phase

580J*05

4 Ton Horizontal Supply

4 Ton Vertical Supply

3 Phase

3 Phase

APPENDIX III. FAN PERFORMANCE cont

580J*05

580J*06

5 Ton Horizontal Supply

5 Ton Vertical Supply

1 Phase

3 Phase

3 Phase

APPENDIX III. FAN PERFORMANCE cont

580J*06

580J*07

6 Ton Horizontal Supply

6 Ton Vertical Supply

3 Phase

3 PHASE

580J*08

7.5 TON HORIZONTAL SUPPLY

7.5 TON VERTICAL SUPPLY

3 PHASE

580J*09

8.5 TON HORIZONTAL SUPPLY

8.5 TON VERTICAL SUPPLY

580J*12

10 TON HORIZONTAL SUPPLY

10 TON VERTICAL SUPPLY

3 PHASE

580J

Pulley Adjustment

APPENDIX III. FAN PERFORMANCE cont

APPENDIX IV. ELECTRICAL DATA

3 TONS

4 TONS

580J*04

APPENDIX IV. ELECTRICAL DATA cont

5 TONS

6 TONS

580J*06

7.5 TONS

8.5 TONS

10 TONS

APPENDIX IV. ELECTRICAL DATA cont

MCA/MOCP Determination No C.O. or UNPWRD C.O

APPENDIX IV. ELECTRICAL DATA cont

580J

See notes on next page

MCA/MOCP DETERMINATION NO C.O. OR UNPWRD C.O

APPENDIX IV. ELECTRICAL DATA cont

580J

1Fuse or breaker

580J

APPENDIX V. WIRING DIAGRAM LIST

Wiring Diagrams

APPENDIX VI. MOTORMASTER SENSOR LOCATIONS

Fig. 54 - 580J*04A, B, C Outdoor Circuiting

Fig. 56 - 580J*07A, C Outdoor Circuiting

Fig. 55 - 580J*05/06A, B, C Outdoor Circuiting

APPENDIX VI. MOTORMASTER SENSOR LOCATIONS cont

Fig. 58 - 580J*09/12A, C Outdoor Circuiting

580J

C08263

START-UPCHECKLIST

TEMPERATURES

Remove and Store in Job File

I.PRELIMINARY INFORMATION

![]()

![]() 30o

30o