-%a-

GENERAL

IMPORTANT: This publication contains controls, op -

eration and troubleshooting data for 3OGNO40-420 and 30GT225, 250, and 280 FlotronicTM II chillers,

Circuits are identified as circuits A and B, and com- pressors are identified as Al, A2, etc. in circuit A, and BI, B2, etc. in circuit B.

Use this guide in conjunction with separate Instal- lation Instructions booklet packaged with the unit,

The 30G Series standard Flotronic II chillers feature microprocessor-based electronic controls and an electronic expansion valve (EXV) in each refrigeration circuit.

NOTE: The 30GN040 and 045 chillers with a factory- installed brine option have thermal expansion valves (TXV) instead of the EXV.

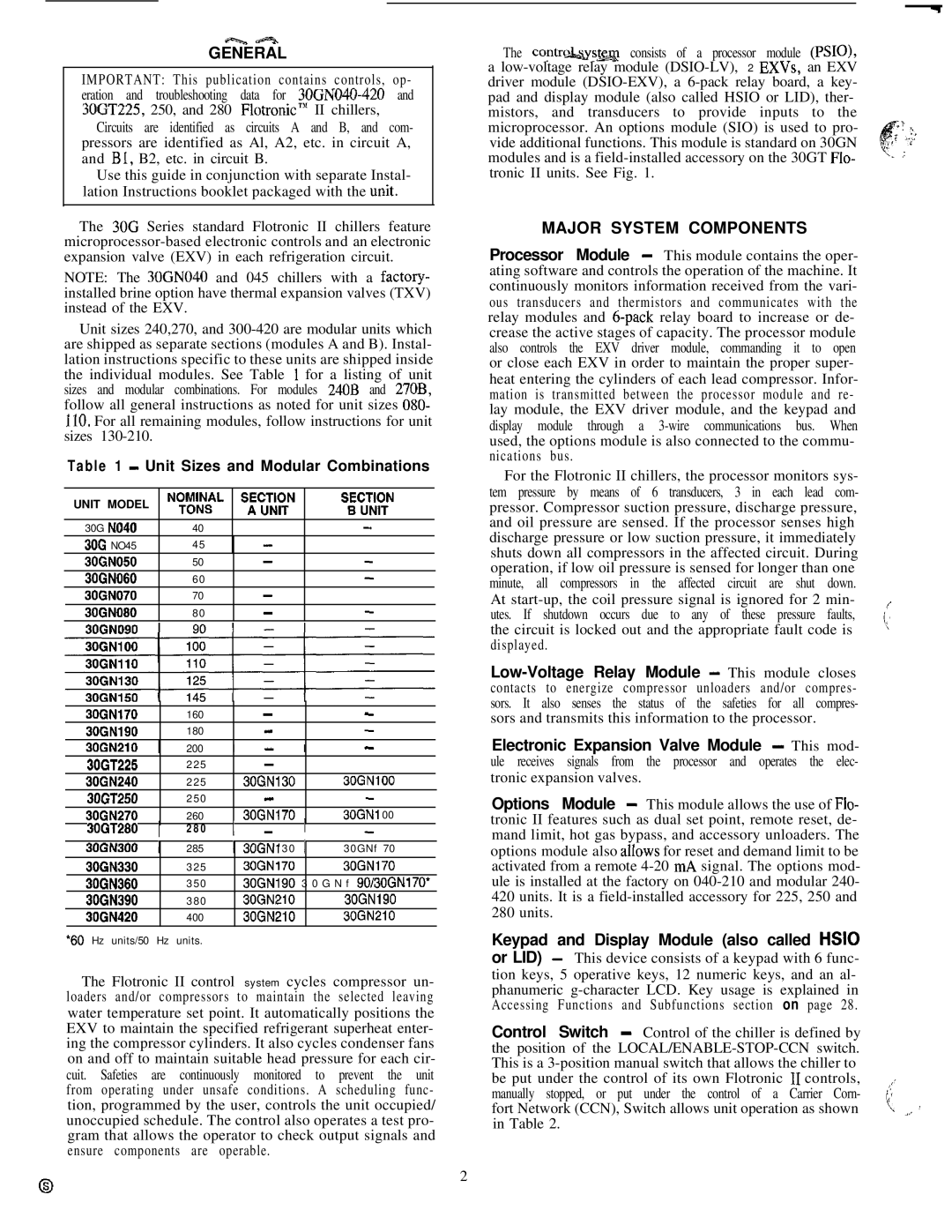

Unit sizes 240,270, and 300-420 are modular units which are shipped as separate sections (modules A and B). Instal- lation instructions specific to these units are shipped inside the individual modules. See Table 1 for a listing of unit sizes and modular combinations. For modules 24OB and 270B, follow all general instructions as noted for unit sizes OSO-

110.For all remaining modules, follow instructions for unit sizes 130-210.

Table 1 - Unit Sizes and Modular Combinations

UNIT MODEL | NoT”o’NNs”L | SE\WlK&N | ssE%~N |

| |

| | |

| | | |

30G NO40 | 40 | | - |

| |

3OG NO45 | 4 5 | - | |

30GN050 | 50 | - | - |

| - |

30EN060 | 6 0 | - |

| |

30GN070 | 70 | - | |

| |

30GN080 | 8 0 | - | - |

| |

| | | | | | | | |

30GNlfO | | 160 | | | - | | | - |

| | | | | | |

30GN190 | | 180 | | | - | | | - |

30GN210 | 1 | 200 | | I | - | I | | - |

| | |

30GT225 | | 2 2 5 | | | - | | | |

30GN240 | | 2 2 5 | | | 30GN130 | | | 30GNlOO |

30GT250 | | 2 5 0 | | | - | | | - |

30GN270 | | 260 | | | 30QN170 | | | 30GNi 00 |

30GT280 | 1 | 2 8 0 | | 1 | - | I | | - |

| | | | | | |

30GN300...--- | 1 | 285 | | 1 30GNi 3 0 | | 1 | 3 0 G N f 70 |

30GN330 | | 3 2 5 | | | 30GNl70 | | | 30GN170 |

30GN360 | | 3 5 0 | | | 30GN190 | 3 0 G N f 90/30GN170* |

30GN390 | | 3 8 0 | | | 30GN210 | | | 30GN190 |

30GN420 | | 400 | | | 30GN210 | | | 30GN210 |

| | | | | | | | |

*60 Hz units/50 Hz units.

The Flotronic II control system cycles compressor un- loaders and/or compressors to maintain the selected leaving water temperature set point. It automatically positions the EXV to maintain the specified refrigerant superheat enter- ing the compressor cylinders. It also cycles condenser fans on and off to maintain suitable head pressure for each cir- cuit. Safeties are continuously monitored to prevent the unit from operating under unsafe conditions. A scheduling func- tion, programmed by the user, controls the unit occupied/ unoccupied schedule. The control also operates a test pro- gram that allows the operator to check output signals and ensure components are operable.

The contrwsm consists of a processor module (PSIO)9 a low-voltage relay module (DSIO-LV), 2 EXVs, an EXV

driver module (DSIO-EXV), a 6-pack relay board, a key- pad and display module (also called HSIO or LID), ther- mistors, and transducers to provide inputs to the microprocessor. An options module (SIO) is used to pro- vide additional functions. This module is standard on 30GN modules and is a field-installed accessory on the 30GT Flo- tronic II units. See Fig. 1.

MAJOR SYSTEM COMPONENTS

Processor Module - This module contains the oper- ating software and controls the operation of the machine. It continuously monitors information received from the vari- ous transducers and thermistors and communicates with the relay modules and &pack relay board to increase or de- crease the active stages of capacity. The processor module also controls the EXV driver module, commanding it to open or close each EXV in order to maintain the proper super- heat entering the cylinders of each lead compressor. Infor- mation is transmitted between the processor module and re- lay module, the EXV driver module, and the keypad and display module through a 3-wire communications bus. When used, the options module is also connected to the commu- nications bus .

For the Flotronic II chillers, the processor monitors sys- tem pressure by means of 6 transducers, 3 in each lead com- pressor. Compressor suction pressure, discharge pressure, and oil pressure are sensed. If the processor senses high discharge pressure or low suction pressure, it immediately shuts down all compressors in the affected circuit. During operation, if low oil pressure is sensed for longer than one minute, all compressors in the affected circuit are shut down. At start-up, the coil pressure signal is ignored for 2 min- utes. If shutdown occurs due to any of these pressure faults, the circuit is locked out and the appropriate fault code is displayed.

Low-Voltage Relay Module - This module closes contacts to energize compressor unloaders and/or compres- sors. It also senses the status of the safeties for all compres- sors and transmits this information to the processor.

Electronic Expansion Valve Module - This mod- ule receives signals from the processor and operates the elec- tronic expansion valves.

Options Module - This module allows the use of Flo- tronic II features such as dual set point, remote reset, de- mand limit, hot gas bypass, and accessory unloaders. The options module also aIlows for reset and demand limit to be activated from a remote 4-20 mA signal. The options mod- ule is installed at the factory on 040-210 and modular 240- 420 units. It is a field-installed accessory for 225, 250 and 280 units.

Keypad and Display Module (also called HSlO or LID) - This device consists of a keypad with 6 func- tion keys, 5 operative keys, 12 numeric keys, and an al- phanumeric g-character LCD. Key usage is explained in Accessing Functions and Subfunctions section on page 28.

Control Switch - Control of the chiller is defined by the position of the LOCAL/ENABLE-STOP-CCN switch. This is a 3-position manual switch that allows the chiller to

be put under the control of its own Flotronic II controls, ,,

manually stopped, or put under the control of a Carrier Corn- :f

fort Network (CCN), Switch allows unit operation as shown c ’ _.  ’ in Table 2.

’ in Table 2.