FIELD CONTROL WIRING — Install a

NOTE: If using a Carrier electronic thermostat, set the thermo- stat configuration for

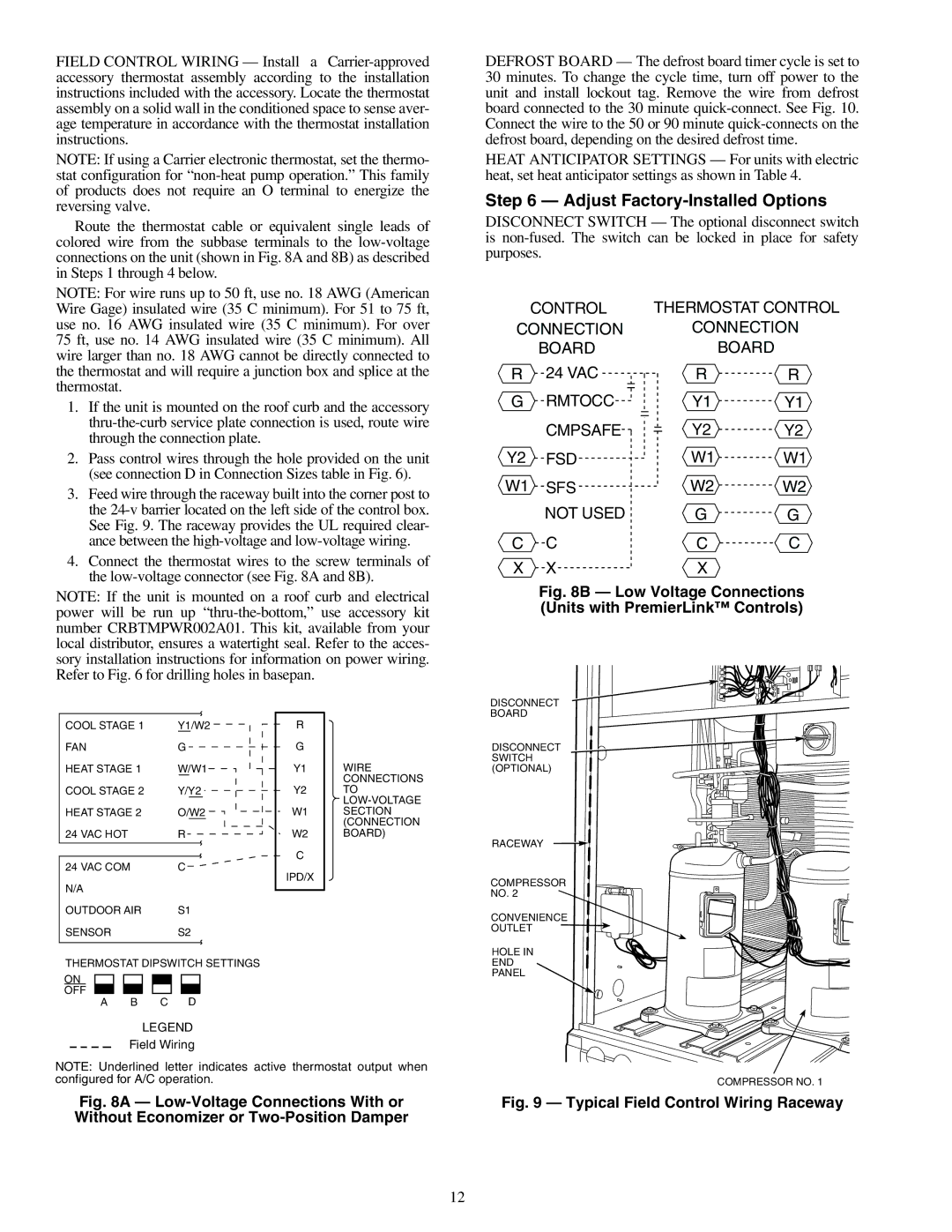

Route the thermostat cable or equivalent single leads of colored wire from the subbase terminals to the

NOTE: For wire runs up to 50 ft, use no. 18 AWG (American Wire Gage) insulated wire (35 C minimum). For 51 to 75 ft, use no. 16 AWG insulated wire (35 C minimum). For over 75 ft, use no. 14 AWG insulated wire (35 C minimum). All wire larger than no. 18 AWG cannot be directly connected to the thermostat and will require a junction box and splice at the thermostat.

1.If the unit is mounted on the roof curb and the accessory

2.Pass control wires through the hole provided on the unit (see connection D in Connection Sizes table in Fig. 6).

3.Feed wire through the raceway built into the corner post to the

4.Connect the thermostat wires to the screw terminals of the

NOTE: If the unit is mounted on a roof curb and electrical power will be run up

DEFROST BOARD — The defrost board timer cycle is set to 30 minutes. To change the cycle time, turn off power to the unit and install lockout tag. Remove the wire from defrost board connected to the 30 minute

HEAT ANTICIPATOR SETTINGS — For units with electric heat, set heat anticipator settings as shown in Table 4.

Step 6 — Adjust Factory-Installed Options

DISCONNECT SWITCH — The optional disconnect switch is

| CONTROL | THERMOSTAT CONTROL | |

CONNECTION | CONNECTION | ||

| BOARD |

| BOARD |

R | 24 VAC | R | R |

G | RMTOCC | Y1 | Y1 |

| CMPSAFE | Y2 | Y2 |

Y2 | FSD | W1 | W1 |

W1 | SFS | W2 | W2 |

| NOT USED | G | G |

C | C | C | C |

X | X | X |

|

Fig. 8B — Low Voltage Connections (Units with PremierLink™ Controls)

DISCONNECT

BOARD

COOL STAGE 1 | Y1/W2 |

FAN | G |

HEAT STAGE 1 | W/W1 |

COOL STAGE 2 | Y/Y2 |

HEAT STAGE 2 | O/W2 |

24 VAC HOT | R |

24 VAC COM | C |

N/A |

|

OUTDOOR AIR | S1 |

SENSOR | S2 |

R

G

Y1

Y2

W1

W2

C

IPD/X

WIRE CONNECTIONS TO

DISCONNECT SWITCH (OPTIONAL)

RACEWAY

COMPRESSOR

NO. 2

CONVENIENCE OUTLET ![]()

THERMOSTAT DIPSWITCH SETTINGS

ON

OFF

A B C D

LEGEND

Field Wiring

NOTE: Underlined letter indicates active thermostat output when configured for A/C operation.

Fig. 8A — Low-Voltage Connections With or Without Economizer or Two-Position Damper

HOLE IN

END

PANEL

COMPRESSOR NO. 1

Fig. 9 — Typical Field Control Wiring Raceway

12