5.4.1.1.1 Ribbon Shield Face Inspection

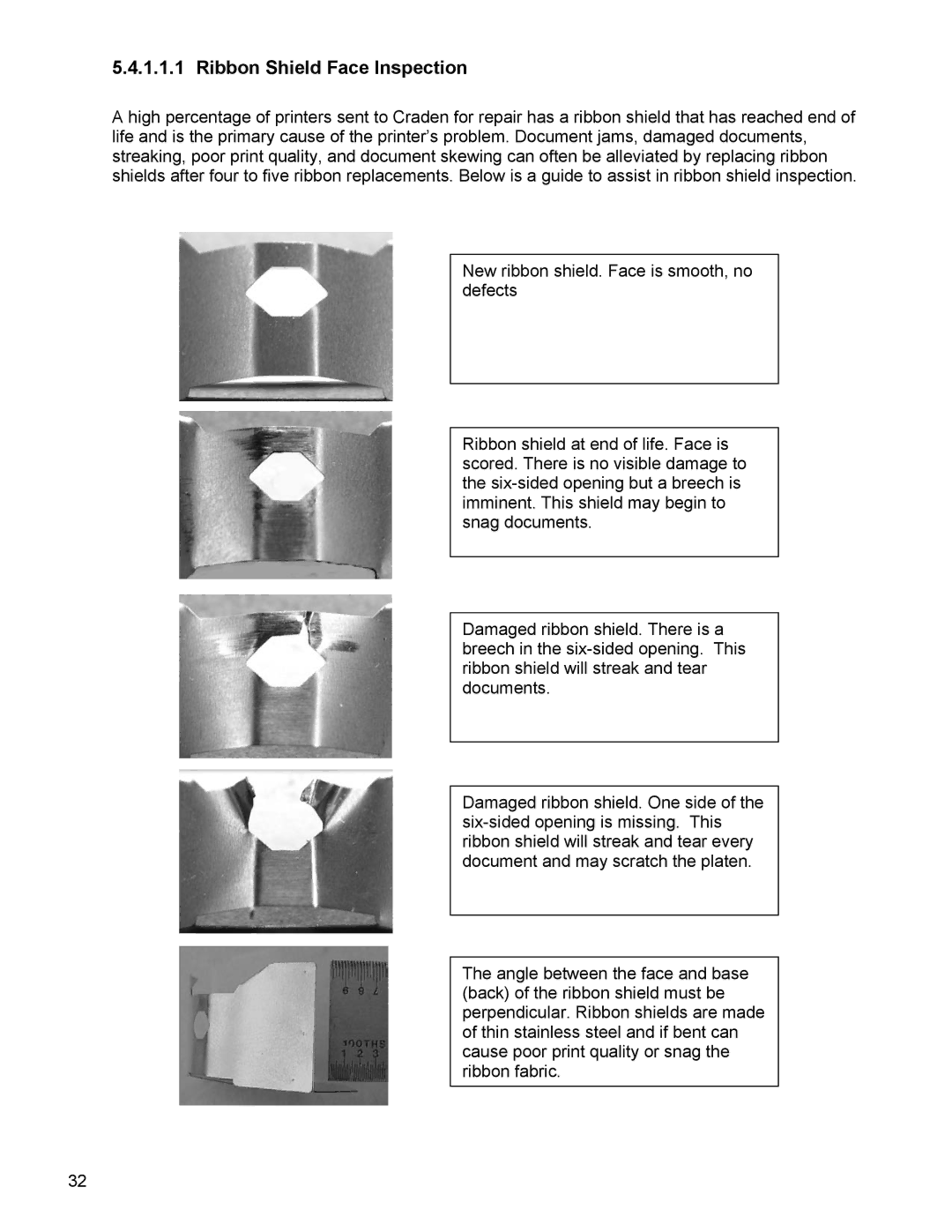

A high percentage of printers sent to Craden for repair has a ribbon shield that has reached end of life and is the primary cause of the printer’s problem. Document jams, damaged documents, streaking, poor print quality, and document skewing can often be alleviated by replacing ribbon shields after four to five ribbon replacements. Below is a guide to assist in ribbon shield inspection.

New ribbon shield. Face is smooth, no defects

Ribbon shield at end of life. Face is scored. There is no visible damage to the

Damaged ribbon shield. There is a breech in the

Damaged ribbon shield. One side of the

The angle between the face and base (back) of the ribbon shield must be perpendicular. Ribbon shields are made of thin stainless steel and if bent can cause poor print quality or snag the ribbon fabric.

32