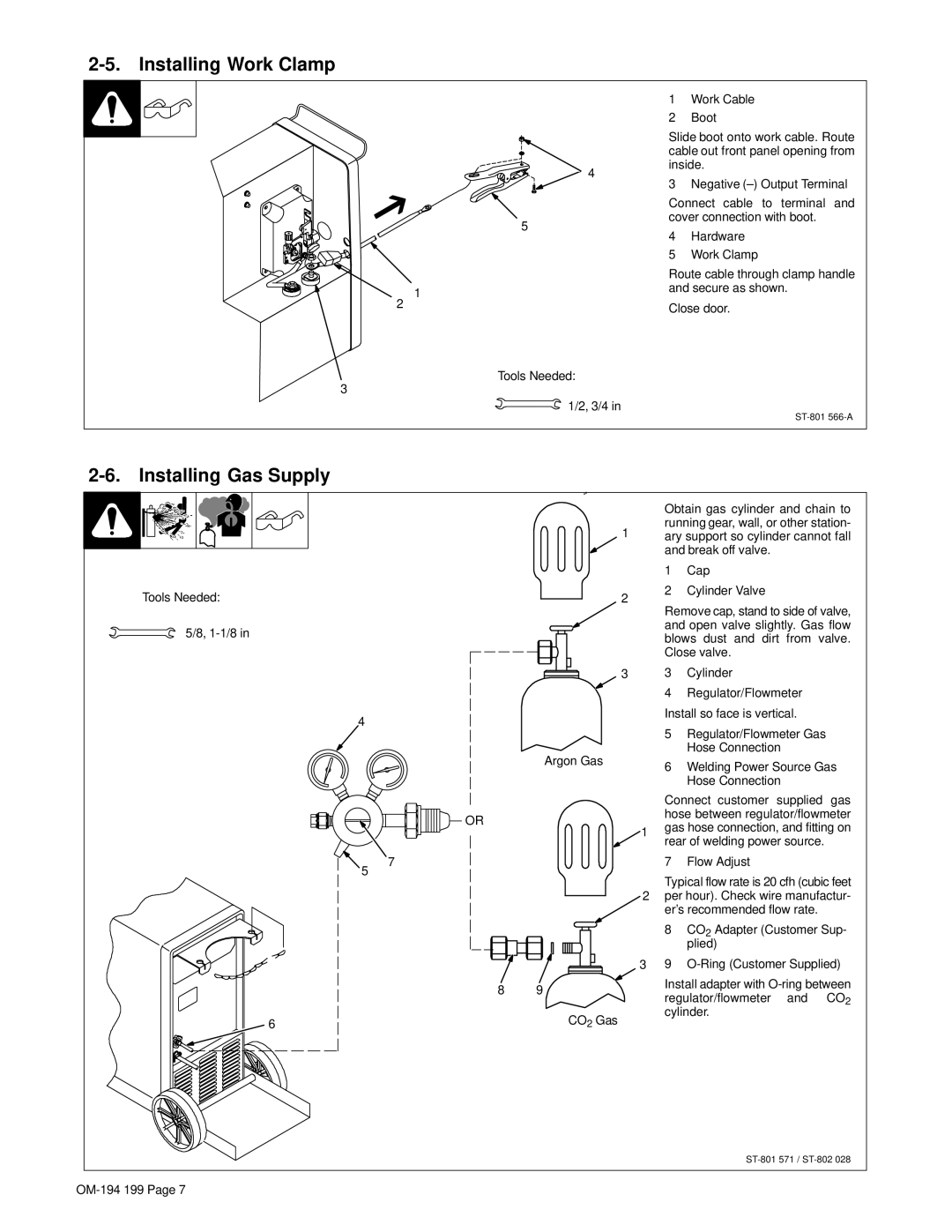

2-5. Installing Work Clamp

4

5

1 Work Cable

2 Boot

Slide boot onto work cable. Route cable out front panel opening from inside.

3 Negative

Connect cable to terminal and cover connection with boot.

4 Hardware

5 Work Clamp

Route cable through clamp handle

| 1 | and secure as shown. |

2 |

| |

| Close door. | |

|

|

Tools Needed:

3

1/2, 3/4 in

2-6. Installing Gas Supply

Tools Needed:

5/8,

|

| Obtain gas cylinder and chain to | ||||

| 1 | running gear, wall, or other station- | ||||

| ary support so cylinder cannot fall | |||||

|

| and break off valve. |

|

| ||

|

| 1 | Cap |

|

| |

| 2 | 2 | Cylinder Valve |

|

| |

| Remove cap, stand to side of valve, | |||||

|

| |||||

|

| and open valve slightly. Gas flow | ||||

|

| blows dust and dirt from valve. | ||||

|

| Close valve. |

|

| ||

| 3 | 3 | Cylinder |

|

| |

|

| 4 | Regulator/Flowmeter |

| ||

4 |

| Install so face is vertical. |

| |||

| 5 | Regulator/Flowmeter Gas |

| |||

|

|

| ||||

| Argon Gas |

| Hose Connection |

| ||

| 6 | Welding Power Source Gas | ||||

|

| |||||

|

|

| Hose Connection |

| ||

|

| Connect customer | supplied | gas | ||

OR |

| hose between regulator/flowmeter | ||||

1 | gas hose connection, and fitting on | |||||

| ||||||

| rear of welding power source. |

| ||||

|

|

| ||||

7 |

| 7 | Flow Adjust |

|

| |

5 |

| Typical flow rate is 20 cfh (cubic feet | ||||

|

| |||||

| 2 | per hour). Check wire manufactur- | ||||

|

| er’s recommended flow rate. |

| |||

|

| 8 | CO2 Adapter (Customer Sup- | |||

|

|

| plied) |

|

| |

| 3 | 9 | ||||

8 | 9 | Install adapter with | ||||

regulator/flowmeter | and | CO2 | ||||

|

| |||||

6 | CO2 Gas | cylinder. |

|

| ||

|

|

|

| |||