Assembly is best done in the area where the saw will be used. When you remove the saw and hardware from the packing materials, carefully check the items with the Loose Parts list. If you are unsure about the description of any part, refer to their illustrations. For your convenience, all fasteners have been drawn actual size. If any parts are missing, delay assembling until you have obtained the missing part(s).

Your radial arm saw is capable of a wide variety of operations, and thus requires a number of initial setup adjustments. However, once the saw is set up, you can check your saw in about ten minutes and correct any misalignment with the procedures in the Adjust- ment section.

,_ CAUTION: Perform all the procedures in both the Assembly and Adjustments sections before

using the saw. Run a check on your saw frequently, referring to the Adjustments section. Failure to perform the adjustments in the initial set up or on a frequent basis can result in poor performance or machine damage.

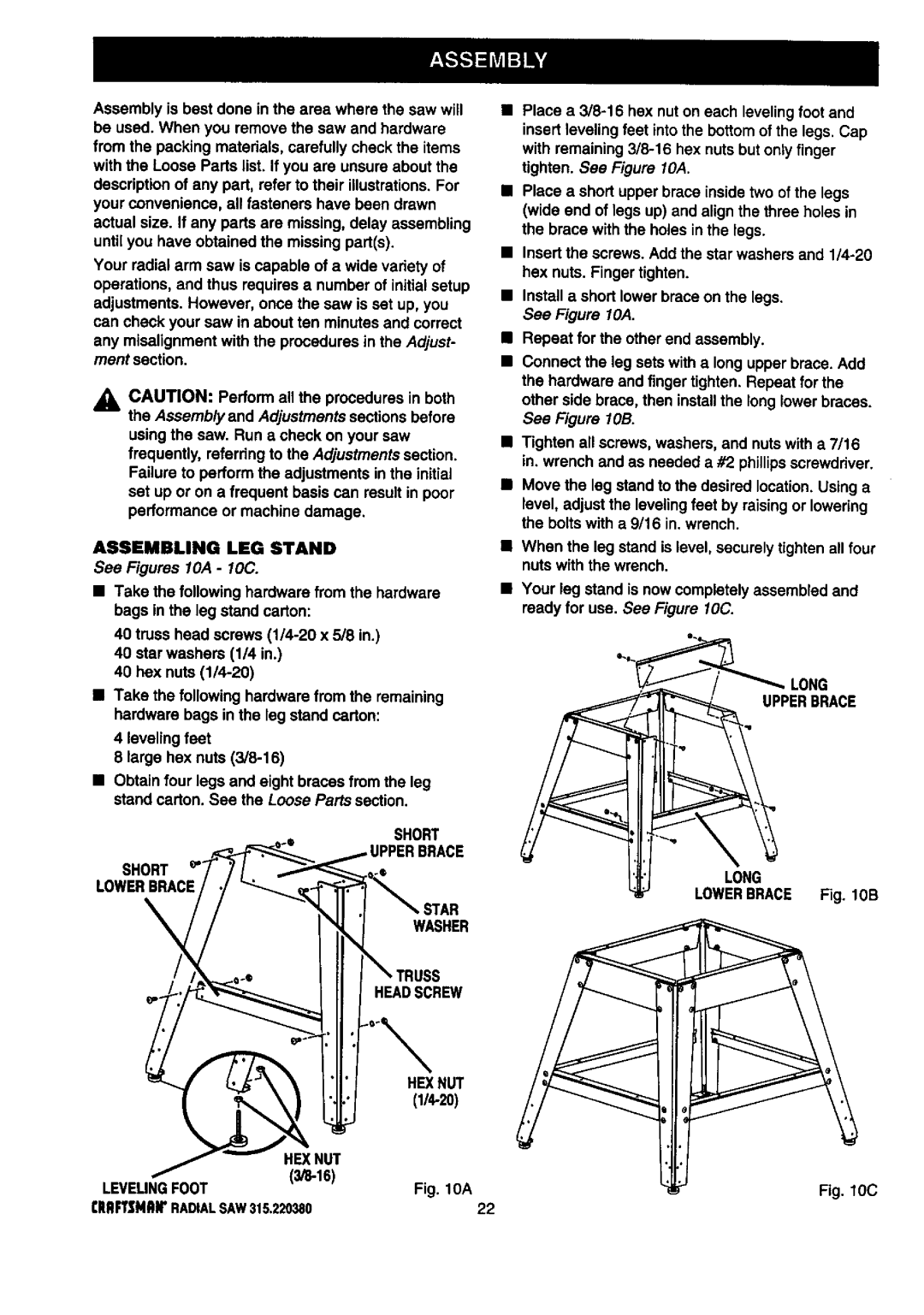

ASSEMBLING LEG STAND

See Figures 10,4 - 10C.

•Take the following hardware from the hardware bags in the leg stand carton:

40 truss head screws

40 star washers (1/4 in.)

40 hex nuts

•Take the following hardware from the remaining hardware bags in the leg stand carton:

4 leveling feet

8 large hex nuts

•Obtain four legs and sight braces from the leg stand carton. See the Loose Parts section.

SHORT

SHORT

LOWERBRACE

WASHER

HEADSCREW

•Place a

•Place a short upper brace inside two of the legs (wide end of legs up) and align the three holes in the brace with the holes in the legs.

•Insert the screws. Add the star washers and

•Install a short lower brace on the legs. See Figure I OA.

•Repeat for the other end assembly.

•Connect the leg sets with a long upper brace. Add the hardware and finger tighten. Repeat for the other side brace, then install the long lower braces. See Figure lOB.

•Tighten all screws, washers, and nuts with a 7/16 in. wrench and as needed a #2 phillips screwdriver.

•Move the leg stand to the desired location. Using a level, adjust the leveling feet by raising or lowering the botts with a 9/16 in. wrench.

•When the leg stand is level, securely tighten all four nuts with the wrench.

•Your leg stand is now completely assembled and reedy for use. See Figure 10C.

. LONG UPPERBRACE

LONG

LOWERBRACE Fig. lOB

HEXNUT

| HEXNUT |

|

|

LEVELINGFOOT | Fig. 10A | OC | |

| |||

|

|

CIIIIFTSMAIr RADIALSAW 315.220380 | 22 |