PARALLELING BLADE TO TABLE

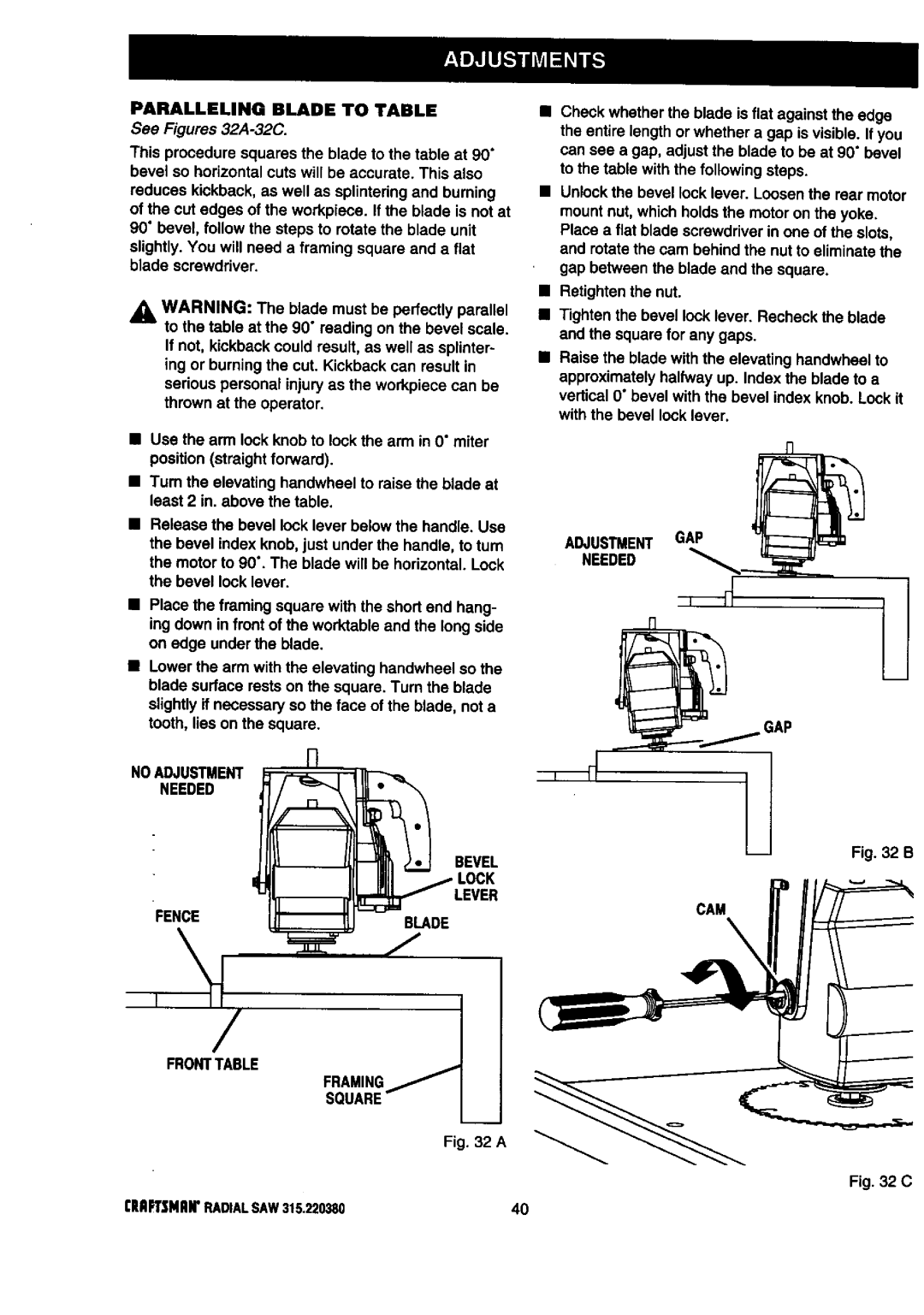

See Figures 32A-32C.

This procedure squares the blade to the table at 90" bevel so horizontal cuts will be accurate. This also

reduces kickback, as well as splintering and burning of the cut edges of the workpieca. If the blade is not at 90" bevel, follow the steps to rotate the blade unit

slightly. You will need a framing square and a flat blade screwdriver.

_1= WARNING: The blade must be perfectly parallel to the table at the 90" reading on the bevel scale. If not, kickback could result, as well as splinter- ing or burning the cut. Kickback can result in sarious personal injury as the workpiece can be thrown at the operator.

BUse the arm lock knob to lock the arm in 0" miter position (straight forward).

•Turn the elevating handwheel to raise the blade at least 2 in. above the table.

BRelease the bevel lock lever below the handle. Use the bevel index knob, just under the handle, to tum the motor to 90 °. The blade will be horizontal. Lock the bevel lock lever.

BPlace the framing square with the short end hang- ing down in front of the worktable and the long side on edge under the blade.

•Lower the arm with the elevating handwheel so the blade surface rests on the square. Tum the blade slightly if necessary so the face of the blade, not a tooth, lies on the square.

ECheck whether the blade is flat against the edge the entire length or whether a gap is visible. If you can see a gap, adjust the blade to be at 90" bevel to the table with the following steps.

•Unlock the bevel lock lever. Loosen the rear motor mount nut, which holds the motor on the yoke. Place a flat blade screwdriver in one of the slots, and rotate the cam behind the nut to eliminate the gap between the blade and the square.

•Retighten the nut.

ETighten the bevel lock lever. Recheck the blade and the square for any gaps.

•Raise the blade with the elevating handwheel to approximately halfway up. Index the blade to a vertical 0 °bevel with the bevel index knob. Lock it with the bevel lock lever.

ADJUSTMENT GAP

NEEDED

GAP

NO ADJUSTMENT

NEEDED

d

| BEVEL | Fig. 32 B |

|

| |

| LOCK |

|

FENCE | BLADE | CAM |

| ||

|

|

FRONTTABLE

FRAMINGJ

SQUARE

Fig. 32 A

Fig. 32 C

CRAFTSMAN'RADIALSAW315.22038040