MAKING A BEVEL CUT

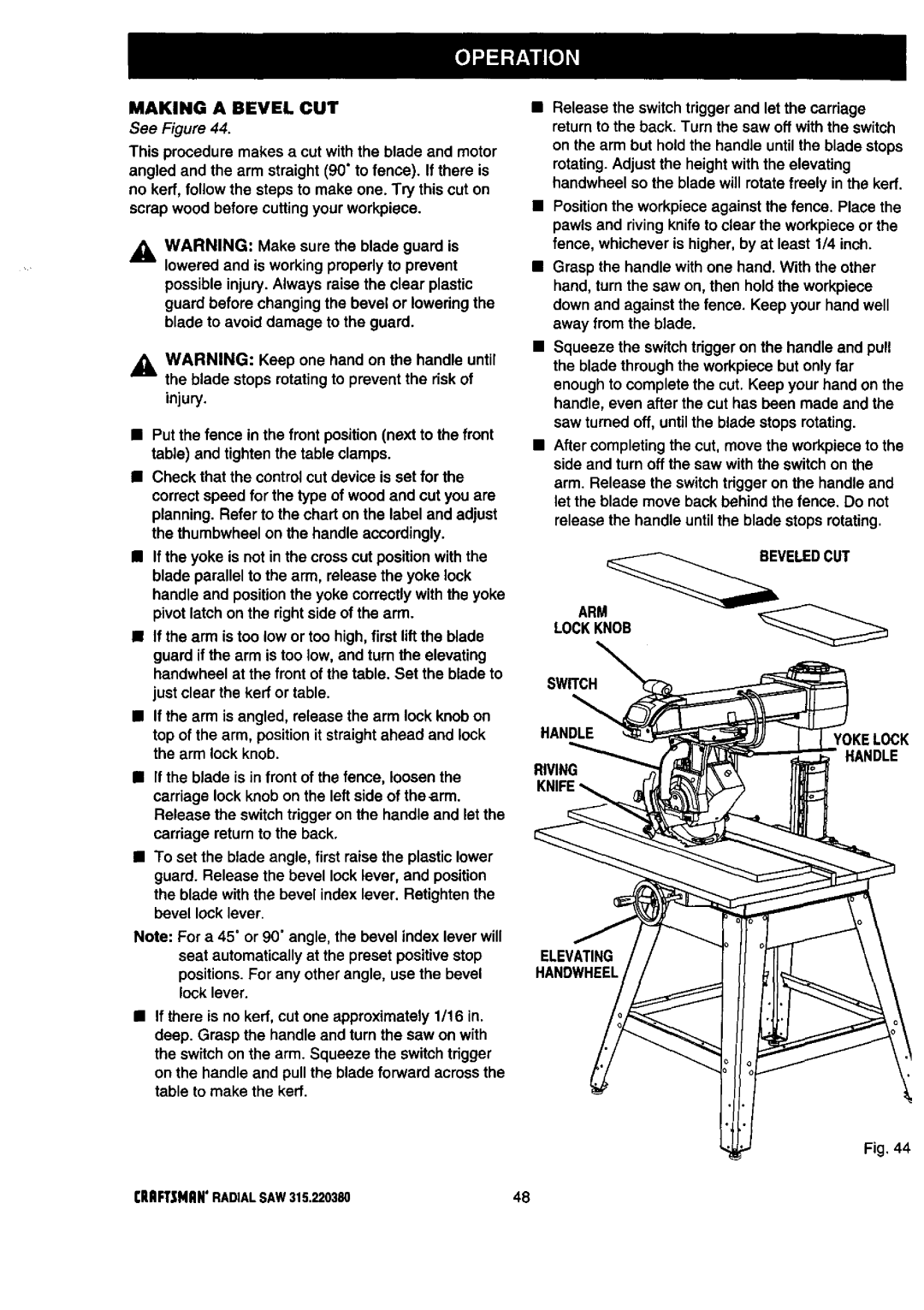

See Figure 44.

This procedure makes a cut with the blade and motor angled and the arm straight (90" to fence). If there is no kerf, follow the steps to make one. Try this cut on scrap wood before cutting your workpiece.

_k WARNING: Make sure the blade guard is lowered and is working properly to prevent

possible injury. Always raise the clear plastic guard before changing the bevel or Iowedng the blade to avoid damage to the guard.

_1, WARNING: Keep one hand on the handle until the blade stops rotating to prevent the risk of

injury.

•Put the fence in the front position (next to the front table) and tighten the table clamps.

•Check that the control cut device is set for the correct speed for the type of wood and cut you are planning. Refer to the chart on the label and adjust the thumbwheel on the handle accordingly.

•If the yoke is not in the cross cut position with the blade parallel to the arm, release the yoke lock handle and position the yoke correctly with the yoke pivot latch on the right side of the arm.

•If the arm is too low or too high, first lift the blade guard if the arm is too low, and turn the elevating handwheel at the front of the table. Set the blade to just clear the kerr or table.

•If the arm is angled, release the arm lock knob on top of the arm, position it straight ahead and lock the arm lock knob.

•If the blade is in front of the fence, loosen the carriage lock knob on the left side of thearm. Release the switch trigger on the handle and let the carriage return to the back.

•To set the blade angle, first raise the plastic lower guard. Release the bevel lock lever, and position the blade with the bevel index lever, Retighten the bevel lock lever.

Note: For a 45" or 90" angle, the bevel index lever will seat automatically at the preset positive stop positions. For any other angle, use the bevel lock lever.

•If there is no kerf, cut one approximately 1/16 in. deep. Grasp the handle and turn the saw on with the switch on the arm. Squeeze the switch trigger on the handle and pull the blade forward across the table to make the kerf.

•Release the switch trigger and let the cardage return to the back. Turn the saw off with the switch on the arm but hold the handle until the blade stops rotating. Adjust the height with the elevating handwheel so the blade will rotate freely in the kert.

•Position the workpiece against the fence. Place the pawls and riving knife to clear the workpiece or the fence, whichever is higher, by at least 1/4 inch.

•Grasp the handle with one hand. With the other hand, turn the saw on, then hold the workpiece down and against the fence. Keep your hand well away from the blade.

•Squeeze the switch tdgger on the handle and pull the blade through the workpiece but only far enough to complete the cut. Keep your hand on the handle, even after the cut has been made and the saw turned off, until the blade stops rotating.

•After completing the cut, move the workpieca to the side and turn off the saw with the switch on the

arm. Release the switch tdgger on the handle and let the blade move back behind the fence. Do not

release the handle until the blade stops rotating.

SWITCH

HANDLEYOKELOCK

HANDLE

RIVING

ELEVATING

HANDWHEEL

Fig. 44

{RAFTSMAN"RADIALSAW 315.220380 | 48 |