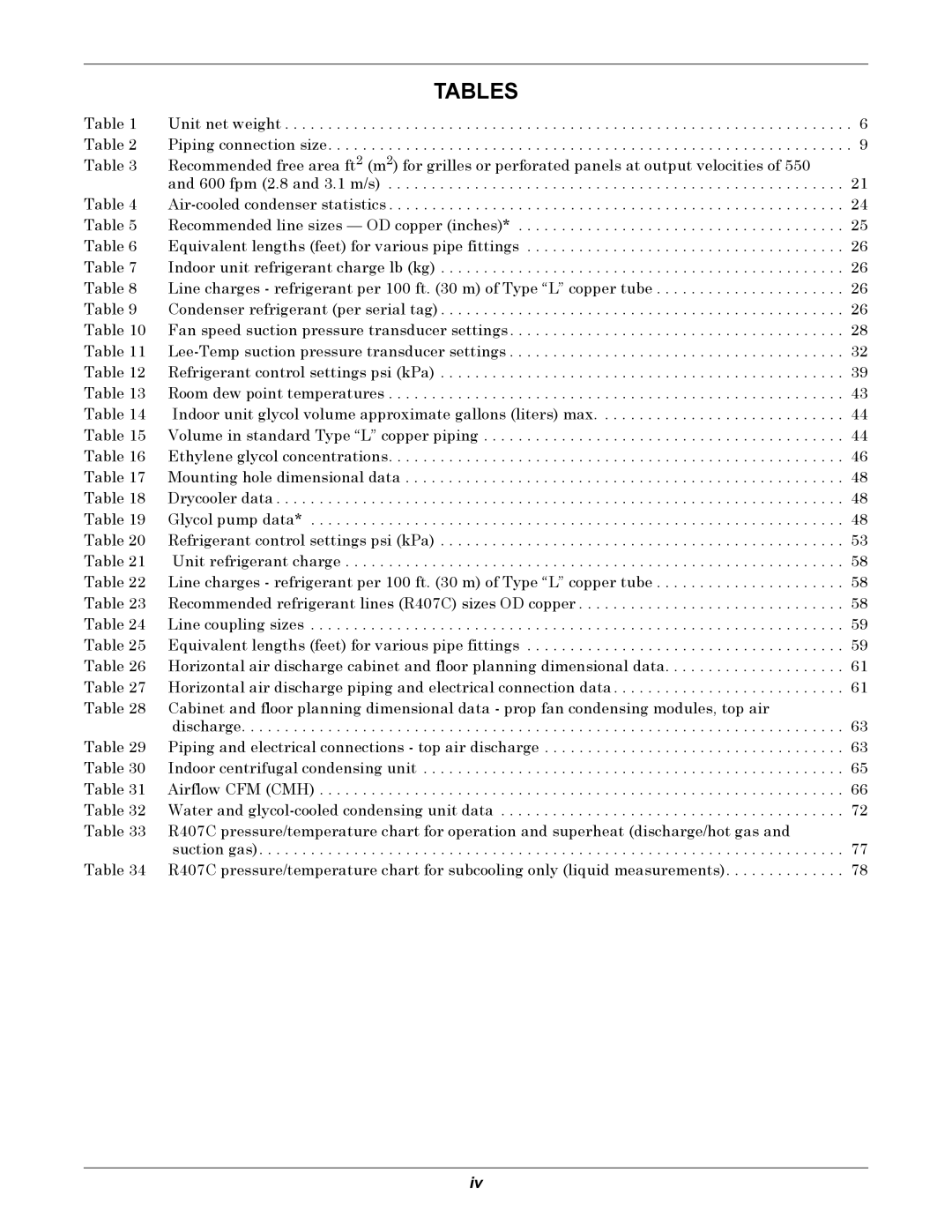

TABLES

Table 1 Unit net weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 Table 2 Piping connection size. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Table 3 Recommended free area ft2 (m2) for grilles or perforated panels at output velocities of 550

and 600 fpm (2.8 and 3.1 m/s) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 Table 4 Air-cooled condenser statistics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24 Table 5 Recommended line sizes — OD copper (inches)* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 Table 6 Equivalent lengths (feet) for various pipe fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26 Table 7 Indoor unit refrigerant charge lb (kg) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26 Table 8 Line charges - refrigerant per 100 ft. (30 m) of Type “L” copper tube . . . . . . . . . . . . . . . . . . . . . . 26 Table 9 Condenser refrigerant (per serial tag) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26 Table 10 Fan speed suction pressure transducer settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28 Table 11 Lee-Temp suction pressure transducer settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32 Table 12 Refrigerant control settings psi (kPa) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39 Table 13 Room dew point temperatures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43 Table 14 Indoor unit glycol volume approximate gallons (liters) max. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44 Table 15 Volume in standard Type “L” copper piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44 Table 16 Ethylene glycol concentrations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46 Table 17 Mounting hole dimensional data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48 Table 18 Drycooler data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48 Table 19 Glycol pump data* . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48 Table 20 Refrigerant control settings psi (kPa) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53 Table 21 Unit refrigerant charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58 Table 22 Line charges - refrigerant per 100 ft. (30 m) of Type “L” copper tube . . . . . . . . . . . . . . . . . . . . . . 58 Table 23 Recommended refrigerant lines (R407C) sizes OD copper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58 Table 24 Line coupling sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59 Table 25 Equivalent lengths (feet) for various pipe fittings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59 Table 26 Horizontal air discharge cabinet and floor planning dimensional data. . . . . . . . . . . . . . . . . . . . . 61 Table 27 Horizontal air discharge piping and electrical connection data . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Table 28 Cabinet and floor planning dimensional data - prop fan condensing modules, top air discharge. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Table 29 Piping and electrical connections - top air discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63 Table 30 Indoor centrifugal condensing unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65 Table 31 Airflow CFM (CMH) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66 Table 32 Water and glycol-cooled condensing unit data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Table 33 R407C pressure/temperature chart for operation and superheat (discharge/hot gas and

suction gas). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77 Table 34 R407C pressure/temperature chart for subcooling only (liquid measurements). . . . . . . . . . . . . . 78