OCX Oxygen/Combustibles Transmitter

Page

Effective January, 2007 Rev

Summary

Page

Table of Contents

Appendix a

Appendix B

OCX Oxygen/Combustibles Transmitter

Essential Instructions

Definitions

Symbols

Preface

Scope System Description

Description and Specifications

Component Checklist System Overview

Typical System Package

OCX

System Configuration

System Features

System Operation

Handling the OCX

System Considerations

OCX 8800 Hart Connections and AMS Application

Integral Electronics

Specifications

General Purpose OCX

Clean, dry atmosphere, two 3/4-14 NPT conduit ports

IM-106-880, Rev January Product Matrix General Purpose OCX

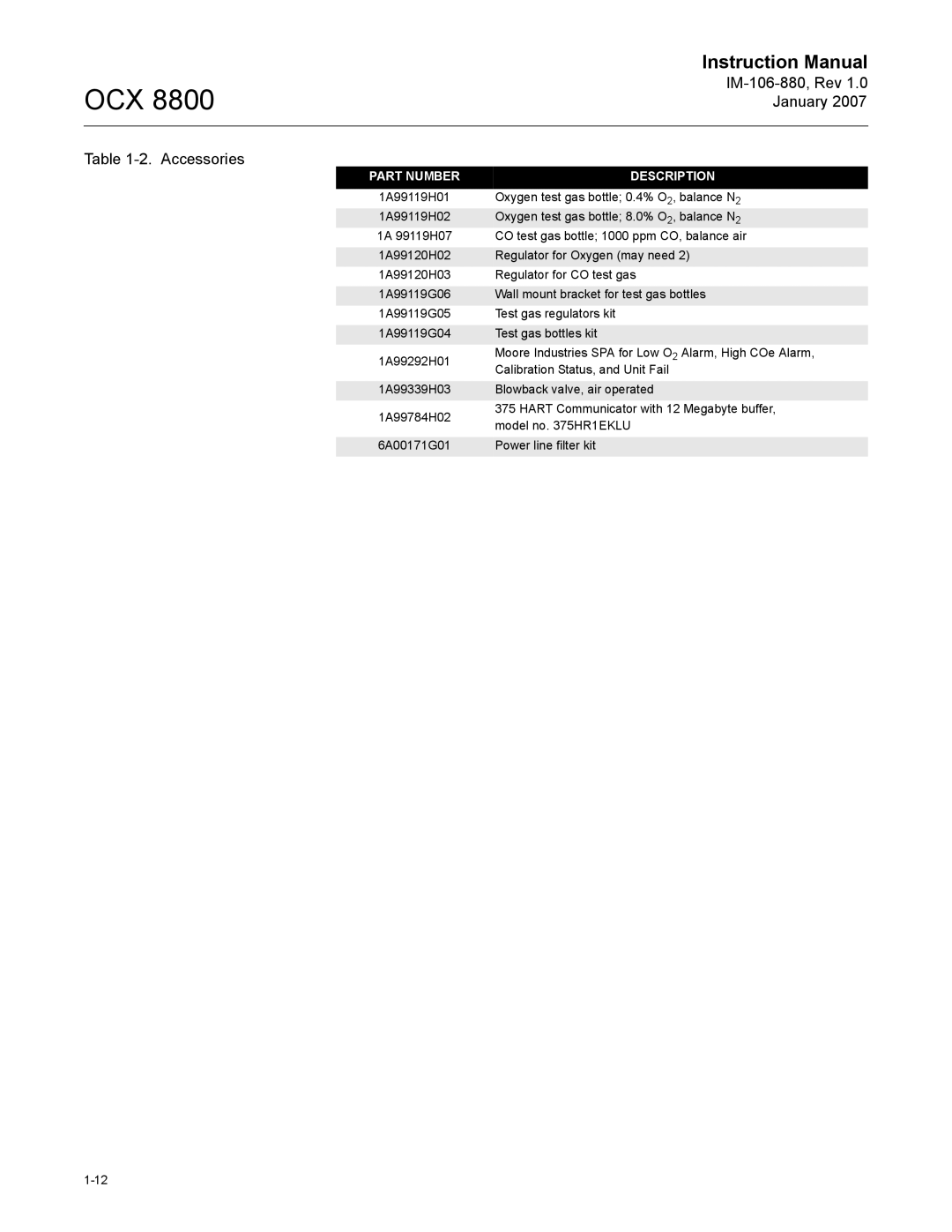

IM-106-880, Rev 1.0 January Accessories

Section Installation

Selecting Location

Mechanical Installation

Installation

Enclosures

Installation, OCX

Adapter Plate Installation

Installation with Drip Loops

Installation

Electrical

Connect 4-20 mA Signals

O2 4-20 mA Signal

COe 4-20 mA Signal

Alarm Output Relay

TOP View 1/2 Size

Pneumatic Installation

Reference Air Set Option only

HIO LOO

Reference Air Set and Solenoids Option

Reference Air Set, Solenoids, and Blowback Option

Piping Arrangement, Blowback with Autocalibration

Piping Arrangement, Blowback without Autocalibration

Initial Startup

Configuration and Startup

Verify Installation

Verify Configuration

Initial Power UP

OCX 8800 Defaults

OCX 8800 Reset Procedure

SET Test GAS Values

Using Hart Communications

Overview Hart Communicator Signal Connections

Signal Line Connections ≥ 250 Ohms Load Resistance

Method 1, for Load Resistance ≥ 250 Ohms

Method 2, for Load Resistance 250 Ohms

OUT

Hart Communicator PC Connections

Off-line and On-line Operations

Hart Menu Tree

Is specific to OCX 8800 applications

Hart Menu Tree Sheet 2 IM-106-880, Rev 1.0 January

Hart Menu Tree Sheet 3

Hart Menu Tree Sheet 4

Trim Procedures O2 D/A trim procedure using HART/AMS

COe D/A trim procedure using HART/AMS

Overview Fully Automatic Calibration

Autocalibration Setup using Hart

Section Calibration

OCX

Operator Initiated Autocalibration Manual Calibration

Autocalibration using Hart

Manual O2 Calibration using Hart

OCX

Manual COe Calibration using Hart

Manual O2 and COe Calibration using Hart

OCX

OCX

Overview

Maintenance and Service

OCX 8800 Removal and Installation

OCX with Integral Electronics

Remove OCX

Electronics Housing Terminal Blocks

Install OCX

Repair Sensor Housing

Remove Cover and Terminals Insulator

Removal of O2 Cell and Heater Strut Assembly

Remove O2 Cell and Heater Strut Assembly

Remove Sample Block Heater Rods

Remove COe Sensor Assembly

COe Sensor Thermocouple, and Heater Connections

Removal COe Sensor Assembly

Alignment COe Sensor Assembly

Remove Eductor

Eductor Alignment Matchmarks

Sensor Housing Sample Tube Exhaust Tube Situ Filter

Disassemble O2 Cell and Heater Strut Assembly

10. O2 Cell, Heater Thermocouple, Exploded View

Disassemble COe Sensor Assembly

11. COe Sensor Exploded View

Sensor Housing Assembly

Assemble COe Sensor Assembly

Assemble O2 Sensor and Heater Strut Assembly

Install Sample and Exhaust Tubes

Install Eductor

14. COe Sensor Parts Alignment

Install COe Sensor Assembly

15. Band Heater Height

16. COe Sensor Holder Alignment

17. COe Sensor Thermocouple, and Heater Connections

18. Installation of O2 Cell and Heater Strut Assembly

Install Sample Block Heater Rods

19. O2 Cell Thermocouple, Heater Connections

Sensor Housing Leak Test

Install O2 Cell and Heater Strut Assembly

Install Terminals Insulator and Cover

Remove Flash Prom

Repair Electronics Housing

Remove Cover

20. Removal/Installation of Electronics Housing Components

Remove Electronics Stack

Remove EMI Filter and Terminal Block

Install EMI Filter and Terminal Block

Remove Solenoid Valves

Install Flash Prom

Install Solenoid Valves

Install Electronics Stack

Electronics Housing

Install Cover

TOP View

‘R’ Type Fitting

Replace Tube Fittings

‘E’ Type Fitting

Install Tube Fittings

Troubleshooting

Grounding Electrical Noise Electrostatic Discharge

Total Power Loss

Diagnostic Alarms

Fault Isolation

Probable Cause Recommended Corrective Action

SB Temp Hi Sample block heater temperature high, 190ºC

SB TC Open Sample block heater thermocouple open

Repair broken wire or loose connection

Oxygen Concentration %

Board Temp Hi Electronics temperature maximum exceeded, 85ºC

Htr Relay Failed Heater relay failure

Electronics Housing Sensor Housing

Alarm Relay Event Alarms/Conditions

OCX

Replacement Parts

O2 Cell and Heater Strut Assembly

Sensor Housing

Sensor Housing Components

Index No Part Number

37390087

Tube, Sample, 9 ft .7 m Inconel

Electronics Housing

Electronics Housing Components

Cover, Window

EMI Filter and Terminal Block

O2 Cell and Heater Strut Assembly

OCX

Appendix a Safety Data

Safety Instructionsimportant

Důležité

Vigtigt

Belangrijk

OCX

Wichtig

Σημαντικο

Oluline Teave

Tärkeää

OCX

Fontos

Importante

Svarbu

Svarīgi

Importanti

Viktig

Ważne

Equipamento só pode ser aberto por técnicos qualificados

Dôležité

Pomembno

Importante

Viktigt

Safety Data Sheet for Ceramic Fiber Products

July 1

Flash Point None

Threshold Limit Value See Section

Exposure to Used Ceramic Fiber Product

Section VI. Reactivity Data STABILITY/CONDITIONS to Avoid

Ventilation

Concentration

High Pressure GAS Cylinders

Appendix B SPA with Hart Alarm

Description

B-1

B-2

Setup

Jumper and Switch Settings

Figure B-3. SPA Jumper Dip Switch Settings

Configuration/Calibration

Figure B-5. SPA Front Panel

OCX

Scle

Appendix C Return of Materials

Returning Material

OCX

Index

Index-2

Warranty

EUROPE, Middle EAST, Africa GAS Chromatography ASIA-PACIFIC