Liebert Xtreme Density

Page

Table of Contents

Specifications

XDH and Liebert Xdcf

Iii

Tables

Liquid Liquid/Vapor Mix CoolFrame, XDH

Liebert Heat Rejection Air Cooled or Water/Glycol Cooled

Direct and Indirect System Configurations

European Union Fluorinated Greenhouse Gas Requirements

Pumped Refrigerant

Liebert XDO-Overhead Cooling Module

Liebert XDV-Vertical, Above-Cabinet Cooling Module

Liebert XDH-Horizontal Cooling Module

Liebert Xdcf

Liebert Xdcf units on BladeFrame EX cabinets

Liebert XDA-Air Flow Enhancer

Liebert XDP-Pumping Unit

Liebert XDP Minimum Load

Liebert XDC-Refrigerant Chiller

Liebert XDC Minimum Load

Liebert XD Field Piping Flexible Piping Kit

Liebert XD field-installed port kits header connection size

Liebert XD Piping

Prefabricated Headers

Determining Cooling Equipment Needs

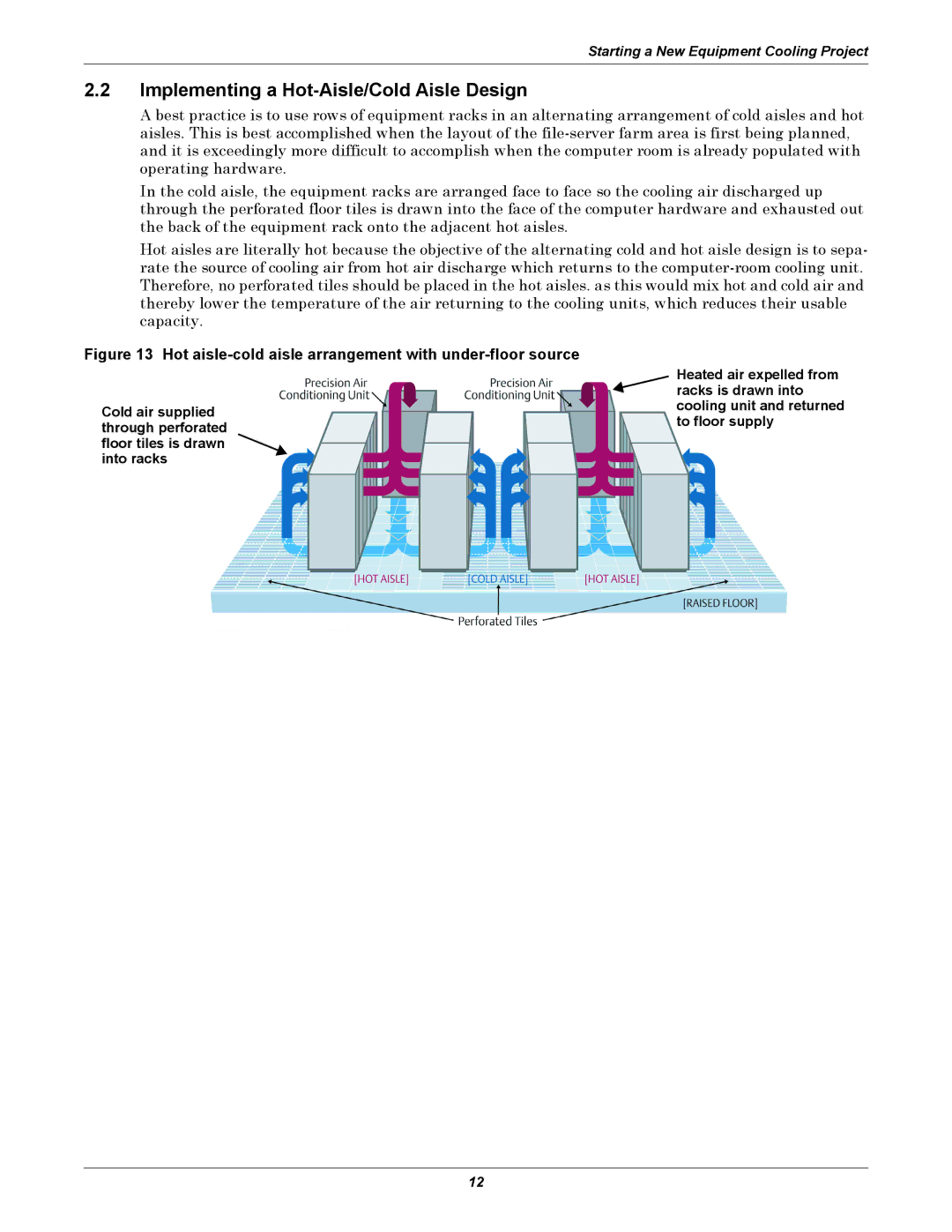

Implementing a Hot-Aisle/Cold Aisle Design

Hot aisle-cold aisle arrangement with under-floor source

Determine Cooling Requirements and Select Liebert XD System

Calculate the Heat Load to be Handled by Liebert XD System

Selecting Liebert XD Cooling Modules

Airflow Requirements for Liebert XD Solutions

Configuring a Liebert XD System

Number of Modules Supported by a Liebert XDP or Liebert XDC

Liebert XDO Placement

Determining Spacing of Liebert XDOs in an Aisle

Liebert XDO spacing-horizontal and vertical

Liebert XDV Unit Placement

Liebert XDV is suspended From ceiling structure

Input Information Step Results

Liebert Xdcf Placement

Liebert Xdcf unit mounting locations

Liebert XDH Placement

Liebert XDP/Liebert XDC Placement

Interlaced piping arrangement

For enhanced protection

Interlaced piping arrangement for enhanced protection

For enhanced

Protection

Liebert XD Refrigerant

Liebert XD Piping System Design

Supply, return pipe sizes for refrigerant loop

Key to Piping Pipe Function Size / Equivalent Pipe Length

Refrigerant Pumped

Liebert XD Piping Slope

Bypass Flow Controllers

XD CoolFrame, XDH, XDO or XDV

Liebert XDP Liebert XDC

Determining Refrigerant Volume

Liebert XDP/Liebert XDC Pumped R-134a Circuit Volume

System refrigerant charge for the supply and return mains

Return Line Diameter 5/8

Return Line Diameter

Calculating refrigerant charge-example

Liebert XDC DX R-407c Circuit Volume-Air Cooled Units

Calculating Refrigerant Charge-Example

Worksheet to calculate refrigerant charge

Outdoor condenser charge-R-407c

Chilled Water Piping

Electrical

Indoor water/glycol cooled module R-407c refrigerant charge

Liebert XDO Standard Features

Optional Features Liebert XDO

Left Side XDO 24-1/8 Rear of XDO

Liebert XDO internal mounting location

Liebert XDV Standard Features

Liebert XDO top and front electrical access points

Optional Features-Liebert XDV

Liebert XDV dimensions

Detail Area a Detail a

Power Source

Liebert XDV electrical connections for CSA-approved units

Suspending single Liebert XDV from Unistruts

Page

Liebert Xdcf Standard Features

Liebert XDP

XD CoolFrame, XDH, XDO or XDV

Liebert Xdcf Mechanical Considerations

Liebert TM

Return Pipe

Liebert Xdcf Installation Considerations

Liebert Xdcf Piping Connection Methods and Points

Egenera BladeFrame

Liebert XDH Standard Features

Optional Features-Liebert XDH

Header System

Liebert XDH dimensions

Supply and return piping connections

Recommended Arc

Or 2-5/8 O.D

Rear XD Cooling Module Either 5/8 or 7/8

Refer to for details

Liebert XD Liebert XDV CoolFrame

Liebert XD Flex Pipe Kit

Liebert XD Flex Pipe assemblies, supply and return

Liebert XDH

Liebert XD Piping Dimensions and Features

Piping Installation Method prefabricated headers

Two-port prefabricated piping legend

Four-port prefabricated piping legend

Branch Piping Standard Run Long Run Four Port 186551G21

Five-port prefabricated piping legend

Branch Piping Standard Run Long Run Five Port

Ten-port prefabricated piping legend

Branch Piping Standard Run Long Run Ten Port 186650G51

Liebert XDP Standard Features

33-1/8 990 1067 XDP160

Unit piping outlet connection sizes, inches, OD Cu

Model Pipe Connection Point 50/60 HZ

Enclosure Cover

Customer Power

Liebert XDC Standard Features

Liebert XDC Optional Features

Liebert XDC piping locations

Liebert XD Chiller piping connection sizes

Liebert XDC Water/Glycol Piping Connection Sizes

Piping locations-floor stand and valve assembly

Front view of Liebert XDC and electrical enclosures

Switch

Transformer

Electrical handy box, factory-installed with cover

Liebert XDC Extra Low Voltage field connections points

Liebert XDC160 specifications

Piping Connections

Performance Data

Heat Rejection Equipment

Performance Data

204

Liebert XDP160 specifications

Liebert XDO16 specifications

Liebert XDO20 specifications

Pipe Connections without flex pipe

Sides, Front and Rear

Liebert XDO20 dimensions-domestic and export

Liebert XDV8 specifications

Liebert XDV10 specifications

Liebert XDV8 dimensions-domestic and export

Liebert XDV10 dimensions-domestic and export

Liebert Xdcf specifications

Liebert XDH specifications

Specifications

Specifications

Page

Ti n

Ne t

Iti

That