BIGLA30 specifications

The Frymaster BIGLA30 is a state-of-the-art commercial frying solution designed to meet the high demands of busy food service environments. Known for its energy efficiency, reliability, and advanced technology, the BIGLA30 has become a favorite among restaurateurs and catering businesses.One of the standout features of the BIGLA30 is its large capacity. With a significant oil capacity, it allows for frying large quantities of food simultaneously, making it ideal for high-volume establishments. This capacity enables kitchens to keep up with demand during peak hours, ensuring that orders are fulfilled quickly and efficiently.

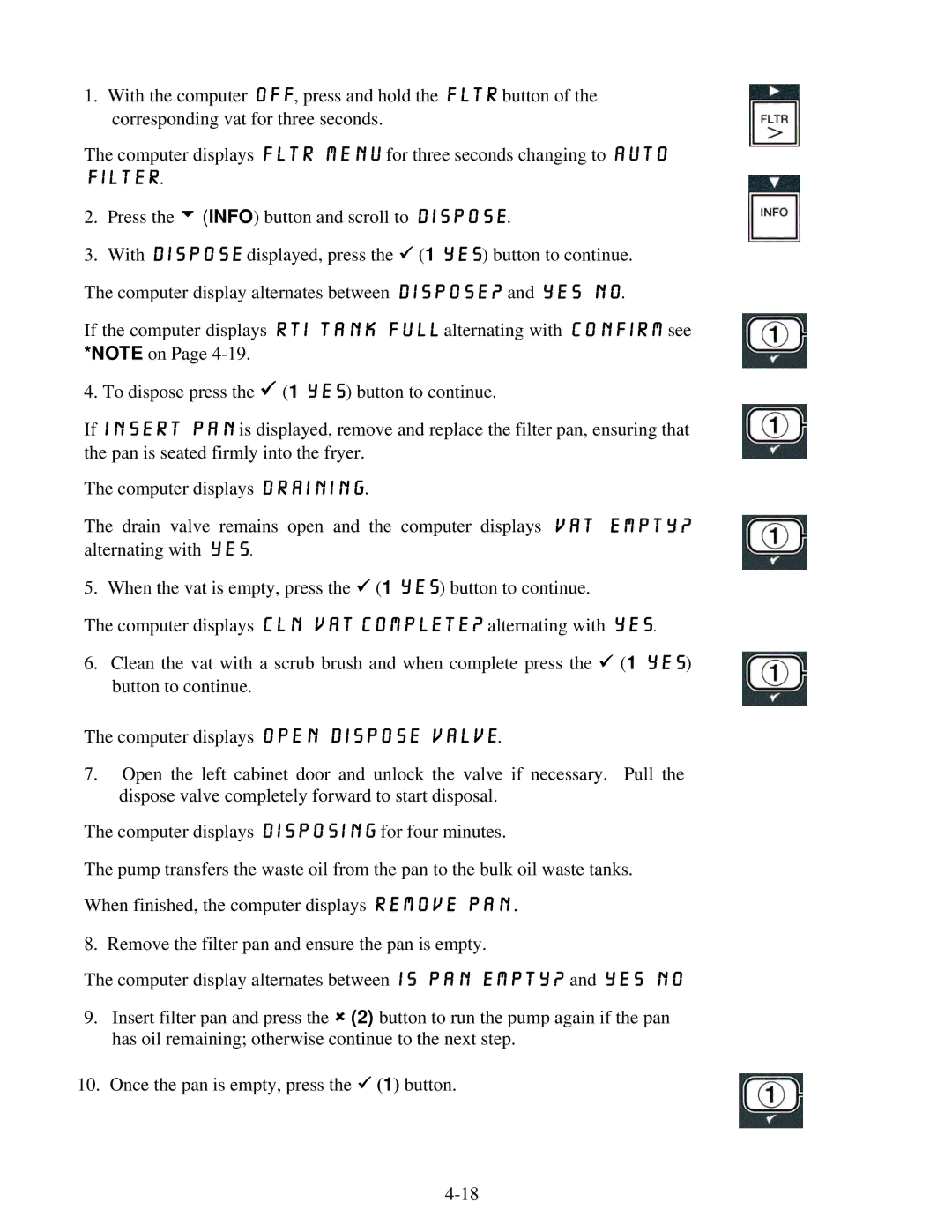

The Frymaster BIGLA30 is equipped with advanced digital controls that simplify the frying process. The intuitive interface allows operators to easily adjust cooking times and temperatures, ensuring consistent results. The digital controls are also equipped with a filtration system that automatically cleans the oil, which prolongs its life and ensures the food maintains optimal flavor.

Another prominent feature of the BIGLA30 is its energy-efficient design. It utilizes innovative heating technology that reduces energy consumption while providing high-performance frying. This not only helps to lower operational costs but also supports environmentally friendly practices within the kitchen.

Safety is paramount in any commercial kitchen, and the BIGLA30 excels in this area. It is designed with safety mechanisms such as automatic shut-off and temperature control systems to prevent overheating. Additionally, the unit features large, easy-to-grip handles on pots, allowing for safe handling and transfer of food items.

In terms of construction, the Frymaster BIGLA30 is built with high-quality materials that ensure durability and longevity. The robust design can withstand the rigors of a busy kitchen and is easy to maintain, reducing downtime and service costs. Its sleek stainless-steel exterior not only presents a professional aesthetic but is also simple to clean, contributing to overall kitchen hygiene.

Furthermore, the BIGLA30 is compatible with various cooking applications, making it versatile enough to fry a wide range of items from crispy fries to delicious chicken. This adaptability makes it a valuable addition to any food service operation.

In summary, the Frymaster BIGLA30 is a top-tier frying solution that combines capacity, energy efficiency, advanced technology, and safety features. Its ability to deliver consistent results while minimizing costs makes it an essential tool for any commercial kitchen.