DEAN MILLIVOLT GAS FRYERS

CHAPTER 3: INSTALLATION INSTRUCTIONS

3.7 Gas Conversion Procedures

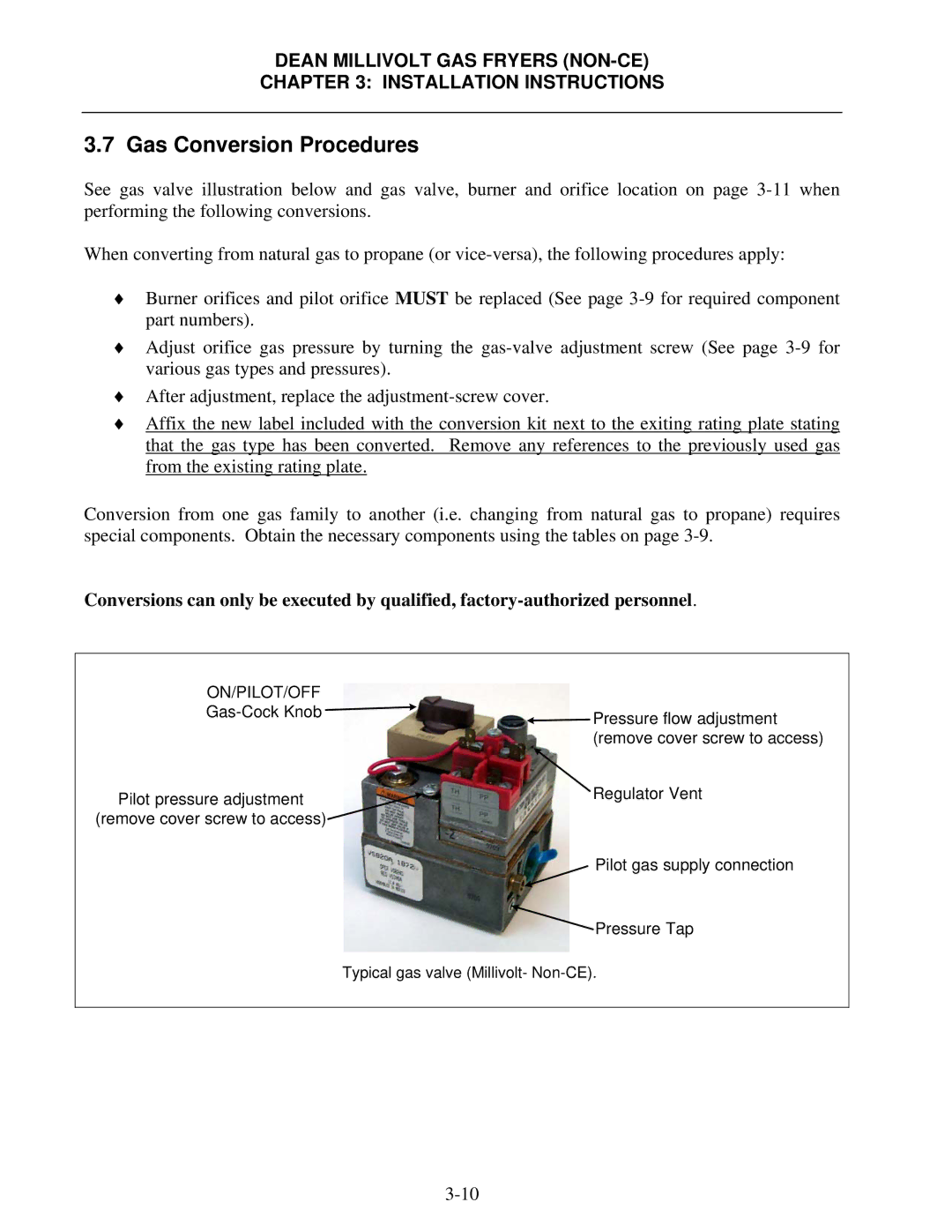

See gas valve illustration below and gas valve, burner and orifice location on page

When converting from natural gas to propane (or

♦Burner orifices and pilot orifice MUST be replaced (See page

♦Adjust orifice gas pressure by turning the

♦After adjustment, replace the

♦Affix the new label included with the conversion kit next to the exiting rating plate stating that the gas type has been converted. Remove any references to the previously used gas from the existing rating plate.

Conversion from one gas family to another (i.e. changing from natural gas to propane) requires special components. Obtain the necessary components using the tables on page

Conversions can only be executed by qualified,

ON/PILOT/OFF |

|

Pressure flow adjustment | |

| |

| (remove cover screw to access) |

Pilot pressure adjustment | Regulator Vent |

(remove cover screw to access) |

|

| Pilot gas supply connection |

| Pressure Tap |

Typical gas valve (Millivolt-