5.Connect feed pumps

a.Install feed pumps (K) in component A and B supply drums. See FIG. 1 and FIG. 2, pages 8 and 9.

b.Seal component A drum and use desiccant dryer (M) in vent.

c.Install agitator (L) in component B drum, if nec- essary.

d.Ensure A and B inlet valves (FV) are closed.

FV

ti10971a

NOTE:

Supply hoses from feed pumps should be 3/4 in. (19

mm)ID.

e.Connect and tighten component A and B supply hose to the 3/4 npt(f) swivel on the component A and B inlet valve.

6.Connect pressure relief lines

Setup

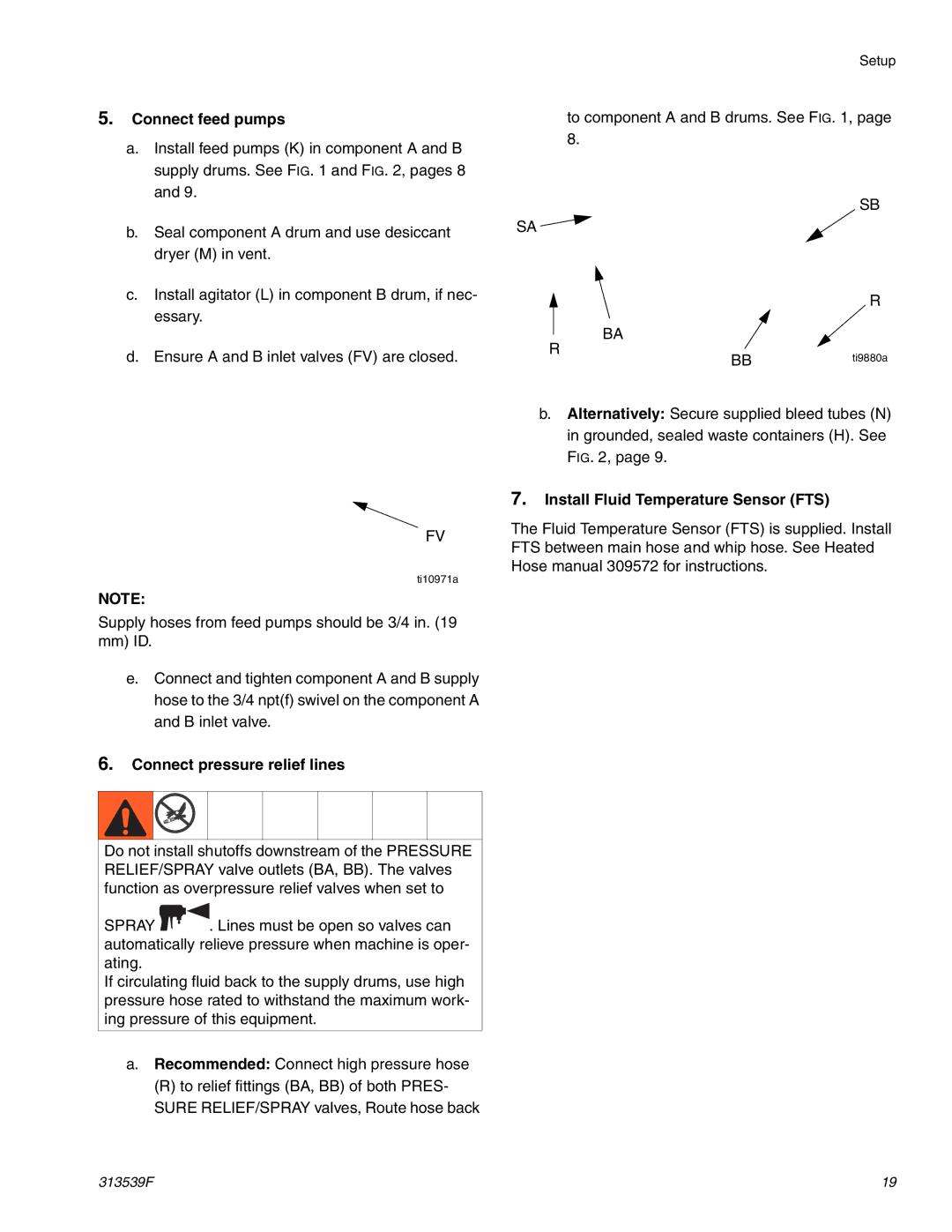

to component A and B drums. See FIG. 1, page 8.

SB

SA ![]()

![]()

R

BA

R

BBti9880a

b.Alternatively: Secure supplied bleed tubes (N) in grounded, sealed waste containers (H). See FIG. 2, page 9.

7.Install Fluid Temperature Sensor (FTS)

The Fluid Temperature Sensor (FTS) is supplied. Install FTS between main hose and whip hose. See Heated Hose manual 309572 for instructions.

Do not install shutoffs downstream of the PRESSURE RELIEF/SPRAY valve outlets (BA, BB). The valves function as overpressure relief valves when set to

SPRAY ![]() . Lines must be open so valves can automatically relieve pressure when machine is oper- ating.

. Lines must be open so valves can automatically relieve pressure when machine is oper- ating.

If circulating fluid back to the supply drums, use high pressure hose rated to withstand the maximum work- ing pressure of this equipment.

a.Recommended: Connect high pressure hose

(R) to relief fittings (BA, BB) of both PRES- SURE RELIEF/SPRAY valves, Route hose back

313539F | 19 |