Priming and Calibration

Machine Priming

Before the machine can be properly calibrated with material, it will need to be primed.

Read all manufacturer’s warning and material MSDS to know the specific hazards of the material used.

From the Run Screen press ![]() then press

then press ![]() . The following screen will be displayed.

. The following screen will be displayed.

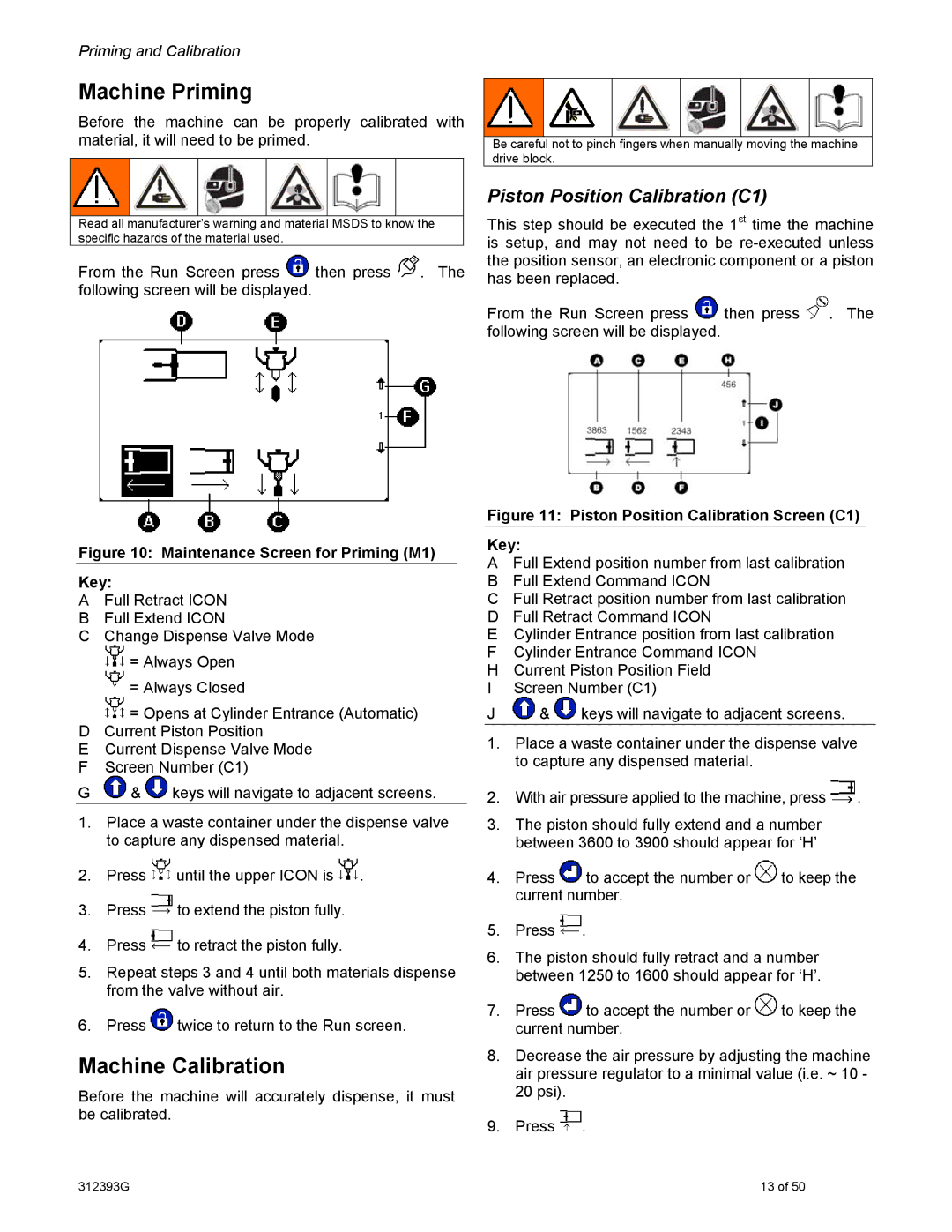

Figure 10: Maintenance Screen for Priming (M1)

Key:

AFull Retract ICON

BFull Extend ICON

CChange Dispense Valve Mode ![]() = Always Open

= Always Open

![]() = Always Closed

= Always Closed

![]() = Opens at Cylinder Entrance (Automatic)

= Opens at Cylinder Entrance (Automatic)

DCurrent Piston Position

ECurrent Dispense Valve Mode

FScreen Number (C1)

G![]() &

& ![]() keys will navigate to adjacent screens.

keys will navigate to adjacent screens.

1.Place a waste container under the dispense valve to capture any dispensed material.

2.Press ![]() until the upper ICON is

until the upper ICON is ![]() .

.

3.Press ![]() to extend the piston fully.

to extend the piston fully.

4.Press ![]() to retract the piston fully.

to retract the piston fully.

5.Repeat steps 3 and 4 until both materials dispense from the valve without air.

6.Press ![]() twice to return to the Run screen.

twice to return to the Run screen.

Machine Calibration

Before the machine will accurately dispense, it must be calibrated.

Be careful not to pinch fingers when manually moving the machine drive block.

Piston Position Calibration (C1)

This step should be executed the 1st time the machine is setup, and may not need to be

From the Run Screen press ![]() then press

then press ![]() . The following screen will be displayed.

. The following screen will be displayed.

Figure 11: Piston Position Calibration Screen (C1)

Key:

AFull Extend position number from last calibration

BFull Extend Command ICON

CFull Retract position number from last calibration

DFull Retract Command ICON

ECylinder Entrance position from last calibration

FCylinder Entrance Command ICON

HCurrent Piston Position Field

IScreen Number (C1)

J![]() &

& ![]() keys will navigate to adjacent screens.

keys will navigate to adjacent screens.

1.Place a waste container under the dispense valve to capture any dispensed material.

2.With air pressure applied to the machine, press ![]() .

.

3.The piston should fully extend and a number between 3600 to 3900 should appear for ‘H’

4.Press ![]() to accept the number or

to accept the number or ![]() to keep the current number.

to keep the current number.

5.Press ![]() .

.

6.The piston should fully retract and a number between 1250 to 1600 should appear for ‘H’.

7.Press ![]() to accept the number or

to accept the number or ![]() to keep the current number.

to keep the current number.

8.Decrease the air pressure by adjusting the machine air pressure regulator to a minimal value (i.e. ~ 10 - 20 psi).

9.Press ![]() .

.

312393G | 13 of 50 |