Priming and Calibration

10.The machine pistons should extend slowly until they encounter the cylinder entrance and a number between 2000 to 2400 should appear for ‘H’.

11.If the pistons do not move, manually move the piston by pulling on the machine drive block, until mechanical resistance is encountered at the cylinder entrance.

12.Press ![]() to accept the number or

to accept the number or ![]() to keep the current number.

to keep the current number.

13.Adjust the Air Pressure Regulator back to a reasonable value for proper machine operation.

14.Press ![]() twice to return to the Run screen.

twice to return to the Run screen.

Phasing (C2)

To enable the machine to dispense the correct ratio of material from the A and B tanks and to mix properly, both materials will need to enter the static mixer at the same time. Phasing shots will need to be executed to visually verify that the 2 materials are exiting the dispense valve at the same time.

Remove any static mixer attached to the dispense valve, and replace it with a ratio check nozzle. Place a waste container under the valve to capture any dispensed material.

From the Run screen, press ![]() , then press

, then press ![]() , and then press

, and then press ![]() once. The following will screen will be displayed.

once. The following will screen will be displayed.

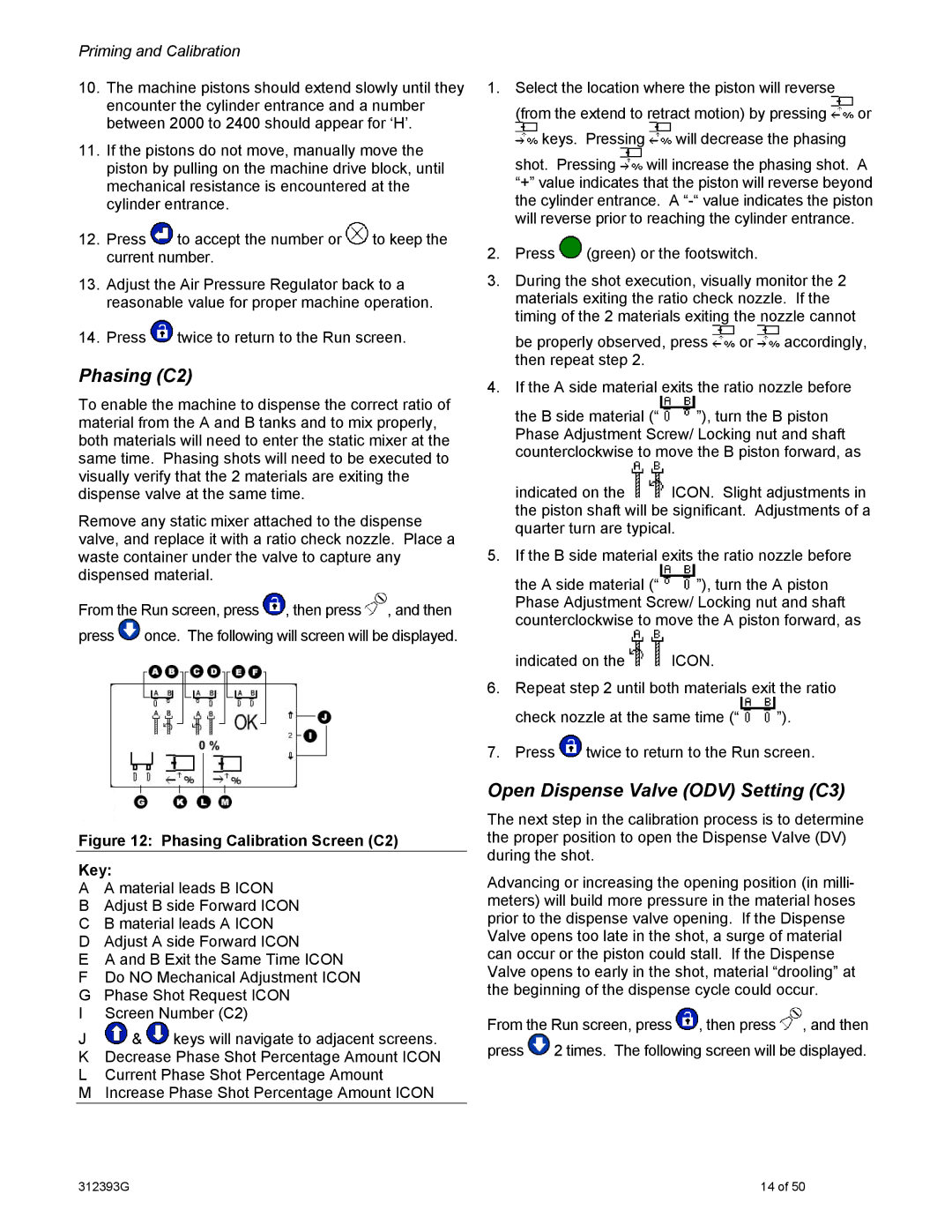

Figure 12: Phasing Calibration Screen (C2)

Key:

AA material leads B ICON

BAdjust B side Forward ICON

CB material leads A ICON

DAdjust A side Forward ICON

EA and B Exit the Same Time ICON

FDo NO Mechanical Adjustment ICON

GPhase Shot Request ICON

IScreen Number (C2)

J![]() &

& ![]() keys will navigate to adjacent screens.

keys will navigate to adjacent screens.

KDecrease Phase Shot Percentage Amount ICON

LCurrent Phase Shot Percentage Amount

MIncrease Phase Shot Percentage Amount ICON

1.Select the location where the piston will reverse (from the extend to retract motion) by pressing ![]() or

or ![]() keys. Pressing

keys. Pressing ![]() will decrease the phasing shot. Pressing

will decrease the phasing shot. Pressing ![]() will increase the phasing shot. A “+” value indicates that the piston will reverse beyond the cylinder entrance. A

will increase the phasing shot. A “+” value indicates that the piston will reverse beyond the cylinder entrance. A

2.Press ![]() (green) or the footswitch.

(green) or the footswitch.

3.During the shot execution, visually monitor the 2 materials exiting the ratio check nozzle. If the timing of the 2 materials exiting the nozzle cannot be properly observed, press ![]() or

or ![]() accordingly, then repeat step 2.

accordingly, then repeat step 2.

4.If the A side material exits the ratio nozzle before

the B side material (“![]() ”), turn the B piston Phase Adjustment Screw/ Locking nut and shaft counterclockwise to move the B piston forward, as

”), turn the B piston Phase Adjustment Screw/ Locking nut and shaft counterclockwise to move the B piston forward, as

indicated on the ![]() ICON. Slight adjustments in the piston shaft will be significant. Adjustments of a quarter turn are typical.

ICON. Slight adjustments in the piston shaft will be significant. Adjustments of a quarter turn are typical.

5.If the B side material exits the ratio nozzle before

the A side material (“![]() ”), turn the A piston Phase Adjustment Screw/ Locking nut and shaft counterclockwise to move the A piston forward, as

”), turn the A piston Phase Adjustment Screw/ Locking nut and shaft counterclockwise to move the A piston forward, as

indicated on the ![]() ICON.

ICON.

6.Repeat step 2 until both materials exit the ratio

check nozzle at the same time (“![]() ”).

”).

7.Press ![]() twice to return to the Run screen.

twice to return to the Run screen.

Open Dispense Valve (ODV) Setting (C3)

The next step in the calibration process is to determine the proper position to open the Dispense Valve (DV) during the shot.

Advancing or increasing the opening position (in milli- meters) will build more pressure in the material hoses prior to the dispense valve opening. If the Dispense Valve opens too late in the shot, a surge of material can occur or the piston could stall. If the Dispense Valve opens to early in the shot, material “drooling” at the beginning of the dispense cycle could occur.

From the Run screen, press ![]() , then press

, then press ![]() , and then press

, and then press ![]() 2 times. The following screen will be displayed.

2 times. The following screen will be displayed.

312393G | 14 of 50 |