Setup

Flush Spray Gun |

|

|

| Adjust Spray Pattern | ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Before running any paint through the spray gun:

1.Flush the gun with a solvent that is compat- ible with the fluid to be sprayed, using the lowest possible fluid pressure and a grounded metal container. See Clean and Flush Gun, page 20.

2.Perform Pressure Relief Procedure, page 18.

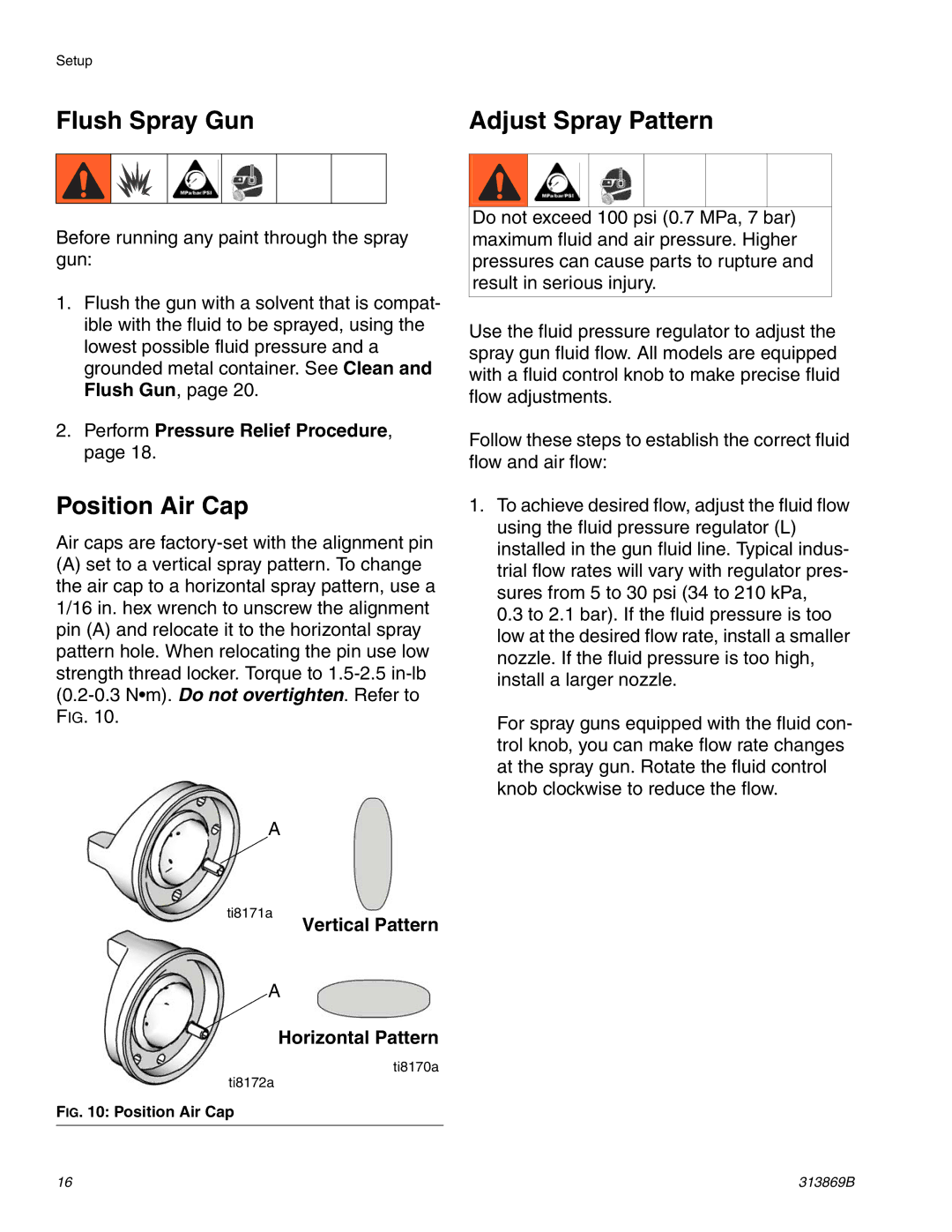

Position Air Cap

Air caps are

(A)set to a vertical spray pattern. To change the air cap to a horizontal spray pattern, use a 1/16 in. hex wrench to unscrew the alignment pin (A) and relocate it to the horizontal spray pattern hole. When relocating the pin use low strength thread locker. Torque to

A

ti8171a

Vertical Pattern

A

Horizontal Pattern

ti8170a

ti8172a

FIG. 10: Position Air Cap

Do not exceed 100 psi (0.7 MPa, 7 bar) maximum fluid and air pressure. Higher pressures can cause parts to rupture and result in serious injury.

Use the fluid pressure regulator to adjust the spray gun fluid flow. All models are equipped with a fluid control knob to make precise fluid flow adjustments.

Follow these steps to establish the correct fluid flow and air flow:

1.To achieve desired flow, adjust the fluid flow using the fluid pressure regulator (L) installed in the gun fluid line. Typical indus- trial flow rates will vary with regulator pres- sures from 5 to 30 psi (34 to 210 kPa,

0.3 to 2.1 bar). If the fluid pressure is too low at the desired flow rate, install a smaller nozzle. If the fluid pressure is too high, install a larger nozzle.

For spray guns equipped with the fluid con- trol knob, you can make flow rate changes at the spray gun. Rotate the fluid control knob clockwise to reduce the flow.

16 | 313869B |