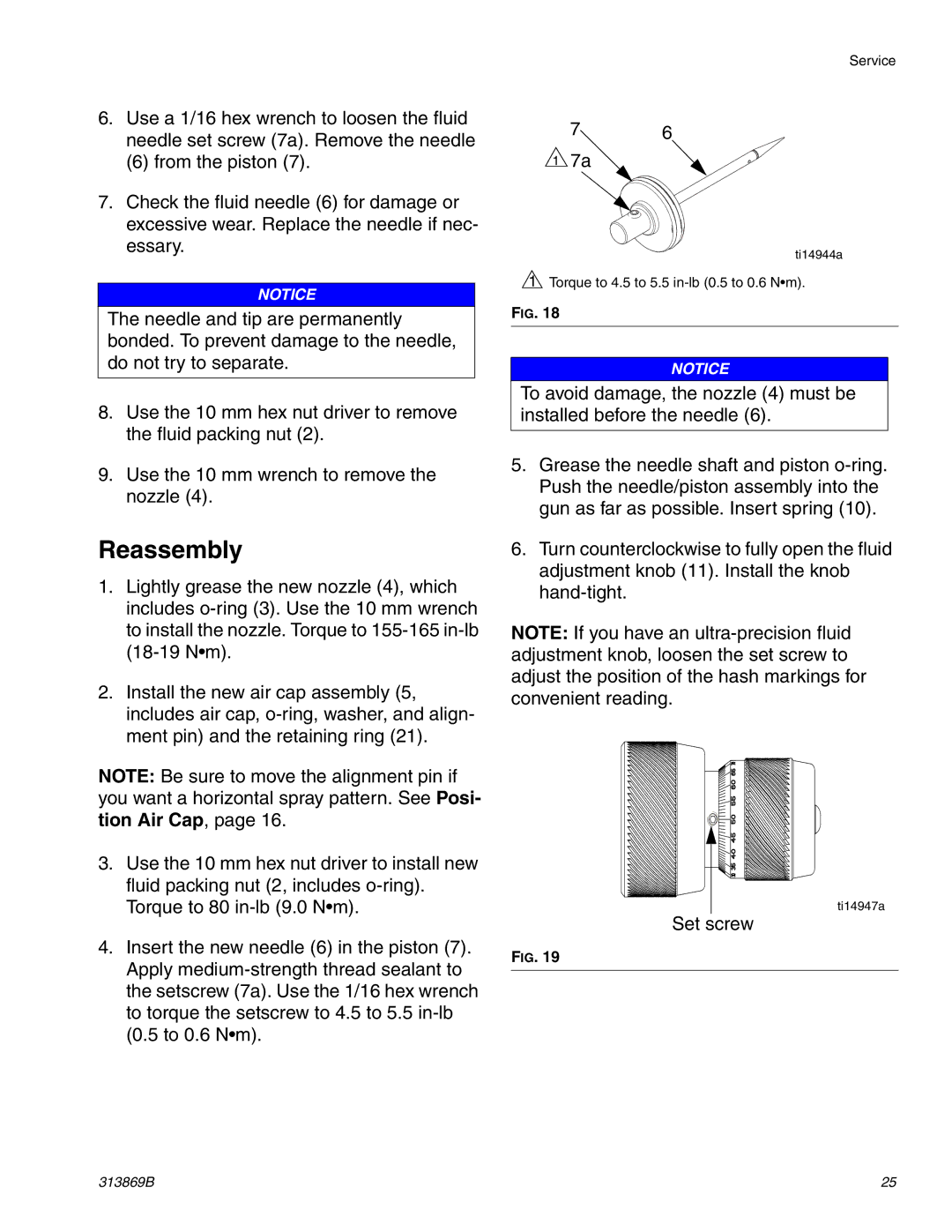

6.Use a 1/16 hex wrench to loosen the fluid needle set screw (7a). Remove the needle

(6) from the piston (7).

7.Check the fluid needle (6) for damage or excessive wear. Replace the needle if nec- essary.

NOTICE

The needle and tip are permanently bonded. To prevent damage to the needle, do not try to separate.

8.Use the 10 mm hex nut driver to remove the fluid packing nut (2).

9.Use the 10 mm wrench to remove the nozzle (4).

Reassembly

1.Lightly grease the new nozzle (4), which includes

2.Install the new air cap assembly (5, includes air cap,

NOTE: Be sure to move the alignment pin if you want a horizontal spray pattern. See Posi- tion Air Cap, page 16.

3.Use the 10 mm hex nut driver to install new fluid packing nut (2, includes

4.Insert the new needle (6) in the piston (7). Apply

Service

76

1 7a

ti14944a

1Torque to 4.5 to 5.5

FIG. 18

NOTICE

To avoid damage, the nozzle (4) must be installed before the needle (6).

5.Grease the needle shaft and piston

6.Turn counterclockwise to fully open the fluid adjustment knob (11). Install the knob

NOTE: If you have an

ti14947a

Set screw

FIG. 19

313869B | 25 |