Chapter 7 FUNCTIONS

7.1.2 Data setting

Data setting related to speed control

Setting item | Function code | Setting Range, Setting Contents |

Orientation speed setting (Note 1) | P015 | 0.00∼ 99.99 / 100.0∼ 120.0 (Hz) |

|

|

|

Orientation direction setting (Note 2) | P016 | 0:Forward / 1:Reverse |

|

|

|

(Note 1) : In order to stop the motor for setting position. (Motor takes 2 rotation to stop setting position)Don’t set high frequency to the orientation speed setting. Otherwise it will be

(Note 2) : Turn direction of the motor while orientation is done based on the setting of P016. Data setting related to position control

Setting item | Function | Setting range, setting contents | |

code | |||

|

| ||

Orientation stop position(Note 3) | P014 | 0. ∼ 4095. | |

|

|

| |

Completion range setting | P017 | 0∼ 9999. / 1000 (10,000) (pulses) | |

(Setting four times fairly of the encoder pulses) | |||

|

| ||

Completion delay time (Note 4) | P018 | 0.00∼ 9.99 | |

Position loop gain(Note 5) | P023 | 0.00∼ 99.99 / 100.0 (rad/s) | |

|

|

|

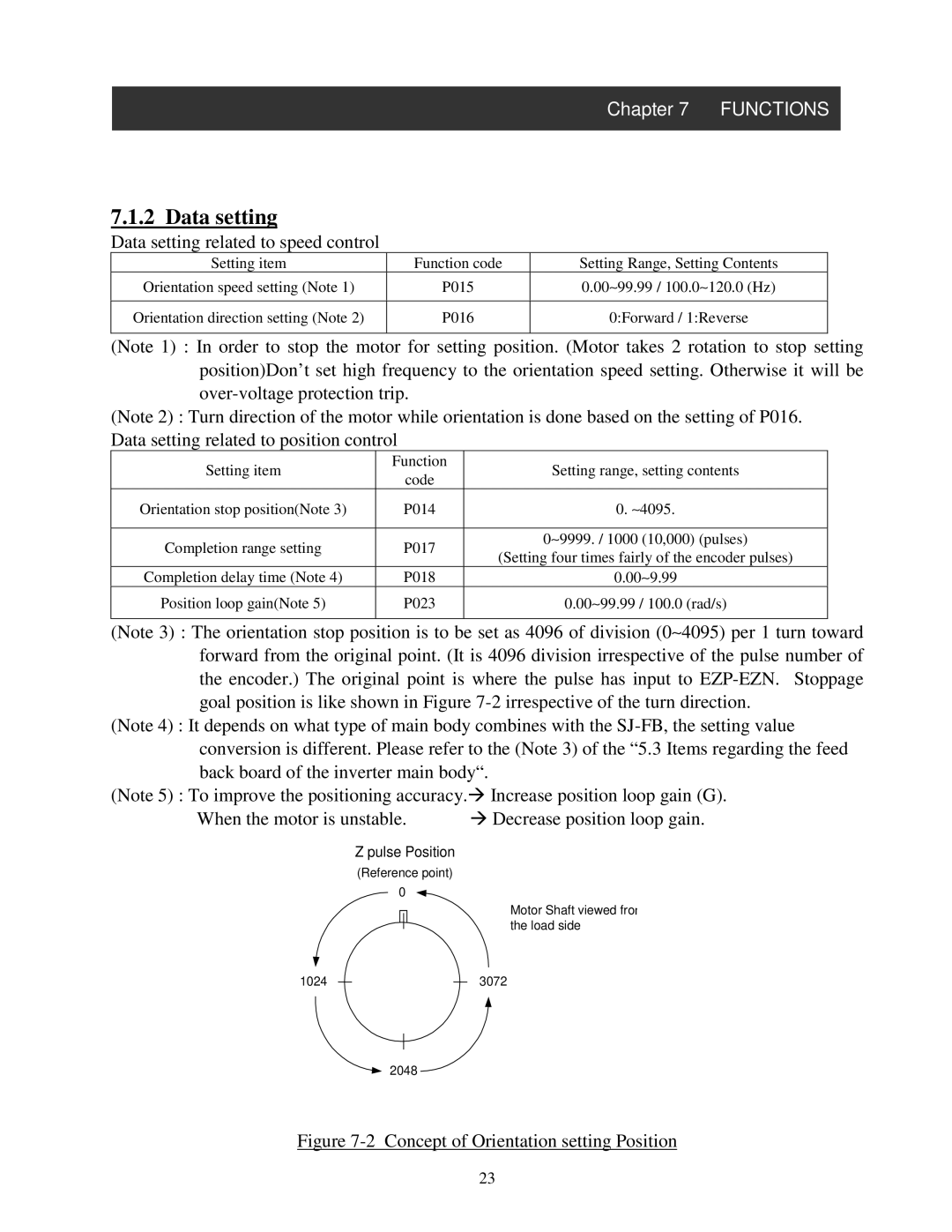

(Note 3) : The orientation stop position is to be set as 4096 of division (0∼ 4095) per 1 turn toward forward from the original point. (It is 4096 division irrespective of the pulse number of the encoder.) The original point is where the pulse has input to

(Note 4) : It depends on what type of main body combines with the

(Note 5) : To improve the positioning accuracy.à Increase position loop gain (G).

When the motor is unstable. | à Decrease position loop gain. |

Z pulse Position

(Reference point) 0 ![]()

Motor Shaft viewed from the load side

10243072

2048

Figure 7-2 Concept of Orientation setting Position

23