7. Control Board Alarms (EA and ED)

"EA" is displayed when an EEPROM write error is detected. "ED" is displayed when an EEPROM verification or read error is detected.

Reset Options

Replacing the control board with a functioning control board will eliminate this alarm condition.

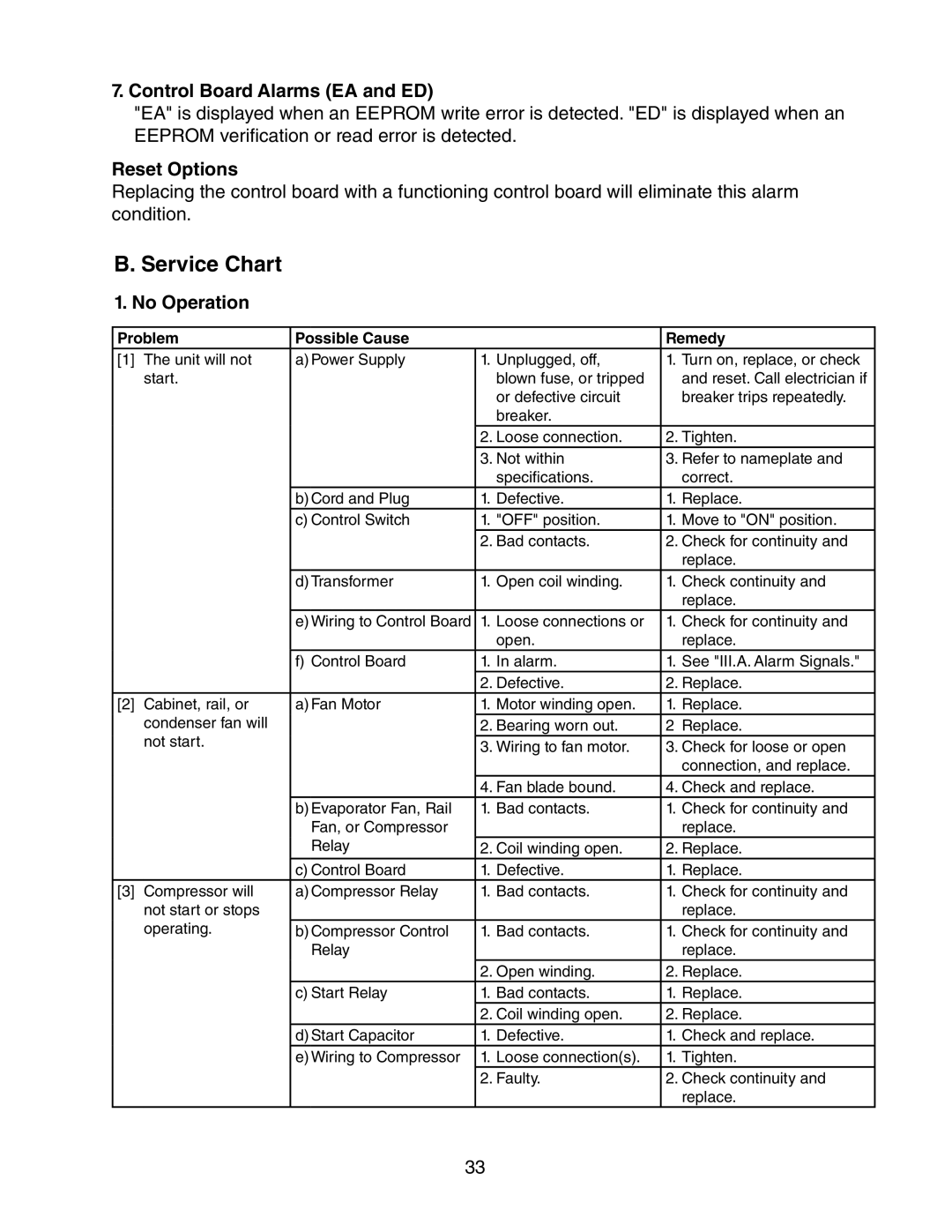

B. Service Chart

1. No Operation

Problem | Possible Cause |

|

| Remedy | ||

[1] | The unit will not | a)Power Supply | 1. | Unplugged, off, | 1. | Turn on, replace, or check |

| start. |

|

| blown fuse, or tripped |

| and reset. Call electrician if |

|

|

|

| or defective circuit |

| breaker trips repeatedly. |

|

|

|

| breaker. |

|

|

|

|

| 2. Loose connection. | 2. Tighten. | ||

|

|

| 3. Not within | 3. Refer to nameplate and | ||

|

|

|

| specifications. |

| correct. |

|

| b)Cord and Plug | 1. | Defective. | 1. | Replace. |

|

| c) Control Switch | 1. | "OFF" position. | 1. | Move to "ON" position. |

|

|

| 2. Bad contacts. | 2. Check for continuity and | ||

|

|

|

|

|

| replace. |

|

| d)Transformer | 1. | Open coil winding. | 1. | Check continuity and |

|

|

|

|

|

| replace. |

|

| e)Wiring to Control Board | 1. | Loose connections or | 1. | Check for continuity and |

|

|

|

| open. |

| replace. |

|

| f) Control Board | 1. | In alarm. | 1. | See "III.A. Alarm Signals." |

|

|

| 2. Defective. | 2. Replace. | ||

[2] | Cabinet, rail, or | a)Fan Motor | 1. | Motor winding open. | 1. | Replace. |

| condenser fan will |

| 2. Bearing worn out. | 2 | Replace. | |

| not start. |

|

|

|

|

|

|

| 3. Wiring to fan motor. | 3. Check for loose or open | |||

|

|

| ||||

|

|

|

|

|

| connection, and replace. |

|

|

| 4. Fan blade bound. | 4. Check and replace. | ||

|

| b)Evaporator Fan, Rail | 1. | Bad contacts. | 1. | Check for continuity and |

|

| Fan, or Compressor |

|

|

| replace. |

|

| Relay | 2. Coil winding open. | 2. Replace. | ||

|

| c) Control Board | 1. | Defective. | 1. | Replace. |

[3] | Compressor will | a)Compressor Relay | 1. | Bad contacts. | 1. | Check for continuity and |

| not start or stops |

|

|

|

| replace. |

| operating. | b) Compressor Control | 1. | Bad contacts. | 1. | Check for continuity and |

|

| Relay |

|

|

| replace. |

|

|

| 2. Open winding. | 2. Replace. | ||

|

| c) Start Relay | 1. | Bad contacts. | 1. | Replace. |

|

|

| 2. Coil winding open. | 2. Replace. | ||

|

| d)Start Capacitor | 1. | Defective. | 1. | Check and replace. |

|

| e)Wiring to Compressor | 1. | Loose connection(s). | 1. | Tighten. |

|

|

| 2. Faulty. | 2. Check continuity and | ||

|

|

|

|

|

| replace. |

33