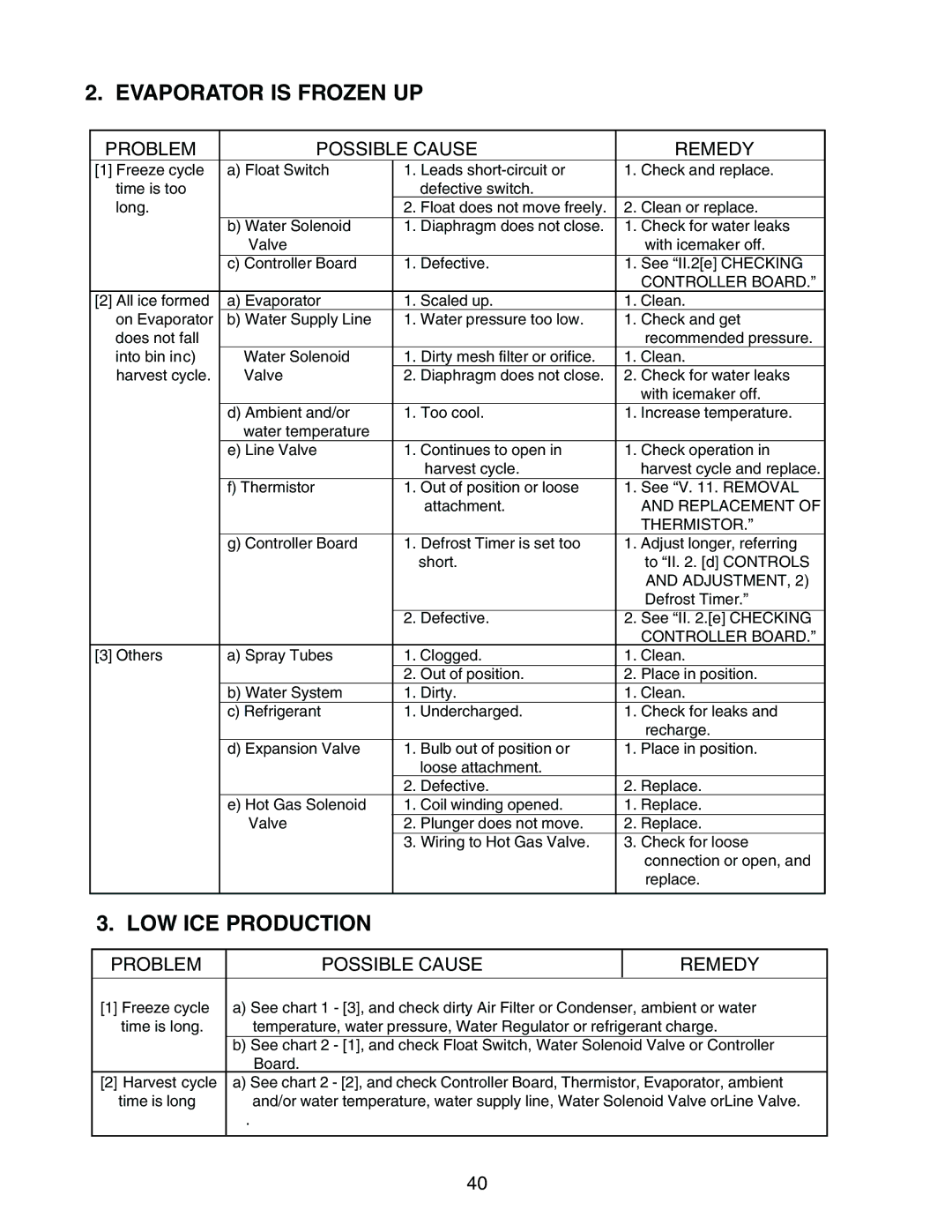

2. EVAPORATOR IS FROZEN UP

PROBLEM | POSSIBLE CAUSE |

| REMEDY | |||||

[1] Freeze cycle | a) Float Switch | 1. | Leads | 1. | Check and replace. | |||

time is too |

|

|

| defective switch. |

|

|

|

|

long. |

|

| 2. | Float does not move freely. | 2. | Clean or replace. | ||

| b) Water Solenoid | 1. | Diaphragm does not close. | 1. | Check for water leaks | |||

| Valve |

|

|

| with icemaker off. | |||

|

|

|

|

|

|

|

|

|

| c) Controller Board | 1. | Defective. | 1. | See “II.2[e] CHECKING | |||

|

|

|

|

|

| CONTROLLER BOARD.” | ||

[2] All ice formed | a) Evaporator | 1. | Scaled up. | 1. | Clean. |

|

| |

on Evaporator | b) Water Supply Line | 1. | Water pressure too low. | 1. | Check and get | |||

does not fall |

|

|

|

|

| recommended pressure. | ||

into bin inc) | Water Solenoid | 1. | Dirty mesh filter or orifice. | 1. | Clean. | |||

harvest cycle. | Valve | 2. | Diaphragm does not close. | 2. | Check for water leaks | |||

|

|

|

|

|

| with icemaker off. | ||

| d) Ambient and/or | 1. | Too cool. | 1. Increase temperature. | ||||

| water temperature |

|

|

|

|

|

| |

| e) Line Valve | 1. | Continues to open in | 1. | Check operation in | |||

|

|

|

| harvest cycle. |

| harvest cycle and replace. | ||

| f) Thermistor | 1. | Out of position or loose | 1. | See “V. 11. REMOVAL | |||

|

|

|

| attachment. |

| AND REPLACEMENT OF | ||

|

|

|

|

|

| THERMISTOR.” | ||

| g) Controller Board | 1. | Defrost Timer is set too | 1. | Adjust longer, referring |

| ||

|

|

|

| short. |

| to “II. 2. [d] CONTROLS | ||

|

|

|

|

|

| AND ADJUSTMENT, 2) | ||

|

|

|

|

|

| Defrost Timer.” | ||

|

|

|

|

|

|

| ||

|

|

| 2. Defective. | 2. | See “II. 2.[e] CHECKING | |||

|

|

|

|

|

| CONTROLLER BOARD.” | ||

[3] Others | a) Spray Tubes | 1. Clogged. | 1. Clean. | |||||

|

|

| 2. | Out of position. | 2. | Place in position. |

| |

| b) Water System | 1. | Dirty. | 1. | Clean. | |||

| c) Refrigerant | 1. Undercharged. | 1. | Check for leaks and | ||||

|

|

|

|

|

| recharge. | ||

| d) Expansion Valve | 1. | Bulb out of position or | 1. | Place in position. | |||

|

|

|

| loose attachment. |

|

|

|

|

|

|

| 2. Defective. | 2. | Replace. | |||

| e) Hot Gas Solenoid | 1. Coil winding opened. | 1. Replace. | |||||

| Valve |

| 2. | Plunger does not move. | 2. Replace. | |||

|

|

| 3. | Wiring to Hot Gas Valve. | 3. | Check for loose | ||

|

|

|

|

|

| connection or open, and | ||

|

|

|

|

|

| replace. | ||

|

|

|

|

|

|

|

|

|

3. LOW ICE PRODUCTION

PROBLEM | POSSIBLE CAUSE | REMEDY |

|

|

|

[1] Freeze cycle | a) See chart 1 - [3], and check dirty Air Filter or Condenser, ambient or water | |

time is long. | temperature, water pressure, Water Regulator or refrigerant charge. | |

| b) See chart 2 - [1], and check Float Switch, Water Solenoid Valve or Controller | |

| Board. |

|

[2] Harvest cycle | a) See chart 2 - [2], and check Controller Board, Thermistor, Evaporator, ambient | |

time is long | and/or water temperature, water supply line, Water Solenoid Valve orLine Valve. | |

| . |

|

|

|

|

40