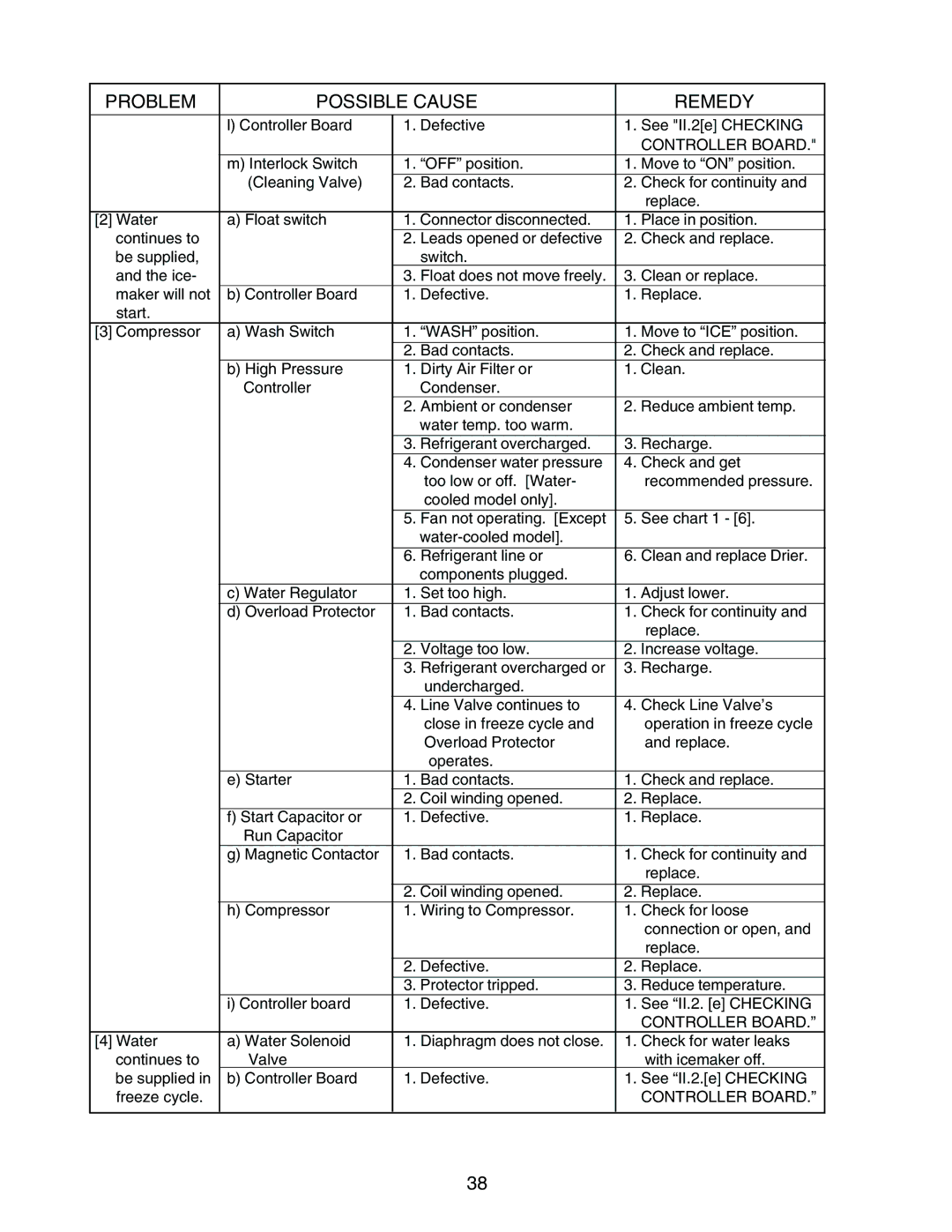

PROBLEM | POSSIBLE CAUSE |

| REMEDY | |||||

|

|

|

|

|

|

|

|

|

|

| l) Controller Board | 1. | Defective | 1. | See "II.2[e] CHECKING | ||

|

|

|

|

|

|

|

| CONTROLLER BOARD." |

|

| m) Interlock Switch | 1. | “OFF” position. | 1. | Move to “ON” position. | ||

|

| (Cleaning Valve) |

| 2. | Bad contacts. | 2. | Check for continuity and | |

|

|

|

|

|

|

|

| replace. |

[2] Water | a) Float switch | 1. | Connector disconnected. | 1. | Place in position. | |||

continues to |

|

|

| 2. | Leads opened or defective | 2. | Check and replace. | |

be supplied, |

|

|

|

| switch. |

|

| |

and the ice- |

|

| 3. | Float does not move freely. | 3. | Clean or replace. | ||

maker will not | b) Controller Board | 1. | Defective. | 1. | Replace. | |||

start. |

|

|

|

|

|

|

| |

[3] Compressor | a) Wash Switch | 1. | “WASH” position. | 1. | Move to “ICE” position. | |||

|

|

|

| 2. | Bad contacts. | 2. | Check and replace. | |

|

| b) High Pressure | 1. | Dirty Air Filter or | 1. | Clean. | ||

|

| Controller |

|

| Condenser. |

|

| |

|

|

|

|

| 2. Ambient or condenser | 2. Reduce ambient temp. | ||

|

|

|

|

|

| water temp. too warm. |

|

|

|

|

|

|

| 3. Refrigerant overcharged. | 3. | Recharge. | |

|

|

|

|

| 4. Condenser water pressure | 4. | Check and get | |

|

|

|

|

|

| too low or off. [Water- |

| recommended pressure. |

|

|

|

|

|

| cooled model only]. |

|

|

|

|

|

| 5. | Fan not operating. [Except | 5. | See chart 1 - [6]. | |

|

|

|

|

|

|

|

| |

|

|

|

| 6. | Refrigerant line or | 6. | Clean and replace Drier. | |

|

|

|

|

|

| components plugged. |

|

|

|

| c) Water Regulator | 1. | Set too high. | 1. | Adjust lower. | ||

|

| d) Overload Protector | 1. | Bad contacts. | 1. | Check for continuity and | ||

|

|

|

|

|

|

|

| replace. |

|

|

|

| 2. | Voltage too low. | 2. | Increase voltage. | |

|

|

|

| 3. | Refrigerant overcharged or | 3. Recharge. | ||

|

|

|

|

|

| undercharged. |

|

|

|

|

|

| 4. | Line Valve continues to | 4. | Check Line Valve’s | |

|

|

|

|

|

| close in freeze cycle and |

| operation in freeze cycle |

|

|

|

|

|

| Overload Protector |

| and replace. |

|

|

|

|

|

| operates. |

|

|

|

| e) Starter | 1. | Bad contacts. | 1. | Check and replace. | ||

|

|

|

| 2. | Coil winding opened. | 2. | Replace. | |

|

| f) Start Capacitor or | 1. | Defective. | 1. | Replace. | ||

|

| Run Capacitor |

|

|

|

|

| |

|

| g) Magnetic Contactor | 1. | Bad contacts. | 1. | Check for continuity and | ||

|

|

|

|

|

|

|

| replace. |

|

|

|

|

|

|

|

| |

|

|

|

| 2. | Coil winding opened. | 2. | Replace. | |

|

| h) Compressor | 1. | Wiring to Compressor. | 1. | Check for loose | ||

|

|

|

|

|

|

|

| connection or open, and |

|

|

|

|

|

|

|

| replace. |

|

|

|

| 2. | Defective. | 2. | Replace. | |

|

|

|

| 3. | Protector tripped. | 3. | Reduce temperature. | |

|

| i) Controller board | 1. | Defective. | 1. | See “II.2. [e] CHECKING | ||

|

|

|

|

|

|

|

| CONTROLLER BOARD.” |

[4] Water | a) Water Solenoid | 1. | Diaphragm does not close. | 1. | Check for water leaks | |||

continues to | Valve |

|

|

|

| with icemaker off. | ||

be supplied in | b) Controller Board | 1. | Defective. | 1. | See “II.2.[e] CHECKING | |||

freeze cycle. |

|

|

|

|

|

| CONTROLLER BOARD.” | |

|

|

|

|

|

|

|

|

|

38