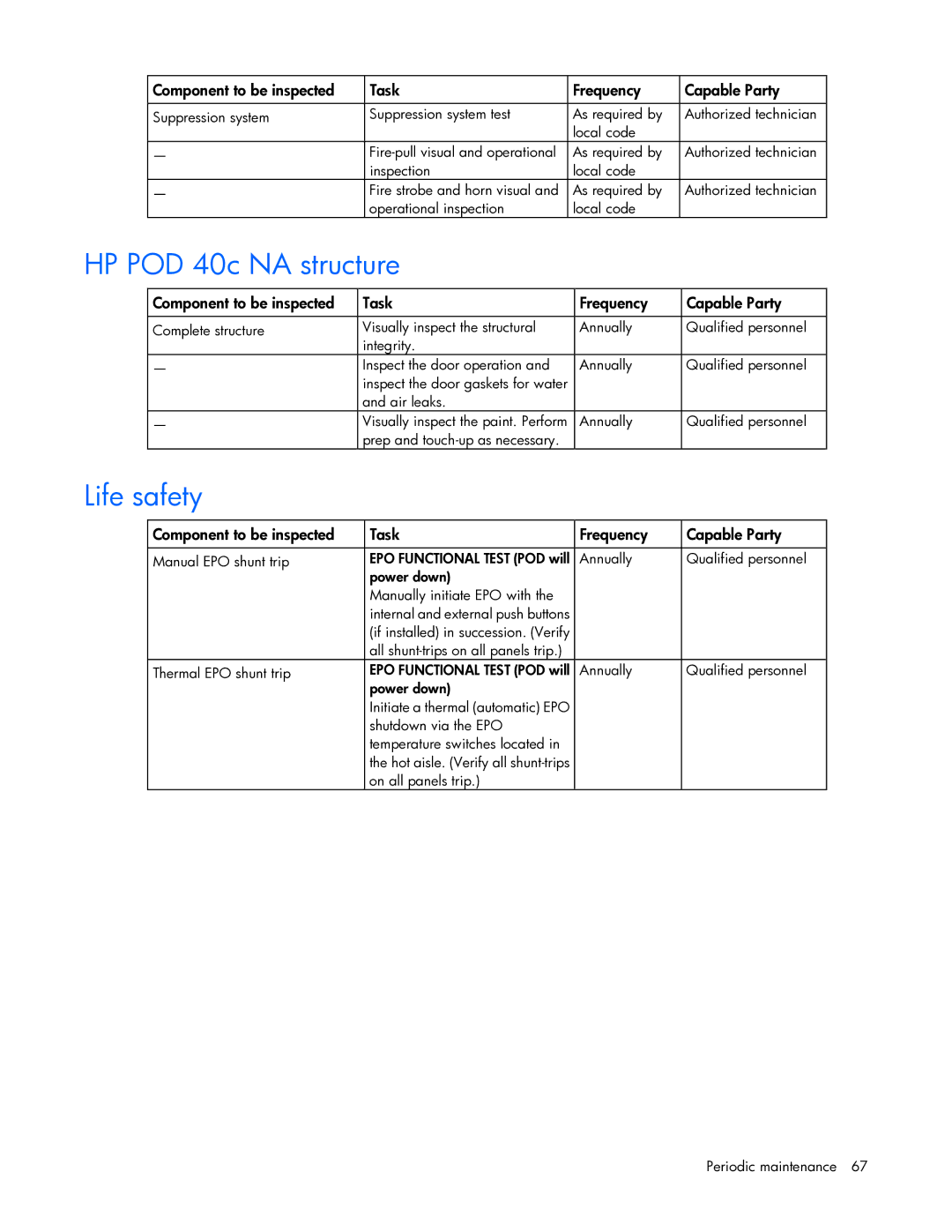

Component to be inspected | Task | Frequency | Capable Party |

|

|

|

|

Suppression system | Suppression system test | As required by | Authorized technician |

|

| local code |

|

— | As required by | Authorized technician | |

| inspection | local code |

|

— | Fire strobe and horn visual and | As required by | Authorized technician |

| operational inspection | local code |

|

HP POD 40c NA structure

Component to be inspected | Task | Frequency | Capable Party |

|

|

|

|

Complete structure | Visually inspect the structural | Annually | Qualified personnel |

| integrity. |

|

|

— | Inspect the door operation and | Annually | Qualified personnel |

| inspect the door gaskets for water |

|

|

| and air leaks. |

|

|

— | Visually inspect the paint. Perform | Annually | Qualified personnel |

| prep and |

|

|

Life safety

Component to be inspected | Task | Frequency | Capable Party |

|

|

|

|

Manual EPO shunt trip | EPO FUNCTIONAL TEST (POD will | Annually | Qualified personnel |

| power down) |

|

|

| Manually initiate EPO with the |

|

|

| internal and external push buttons |

|

|

| (if installed) in succession. (Verify |

|

|

| all |

|

|

Thermal EPO shunt trip | EPO FUNCTIONAL TEST (POD will | Annually | Qualified personnel |

| power down) |

|

|

| Initiate a thermal (automatic) EPO |

|

|

| shutdown via the EPO |

|

|

| temperature switches located in |

|

|

| the hot aisle. (Verify all |

|

|

| on all panels trip.) |

|

|

Periodic maintenance 67