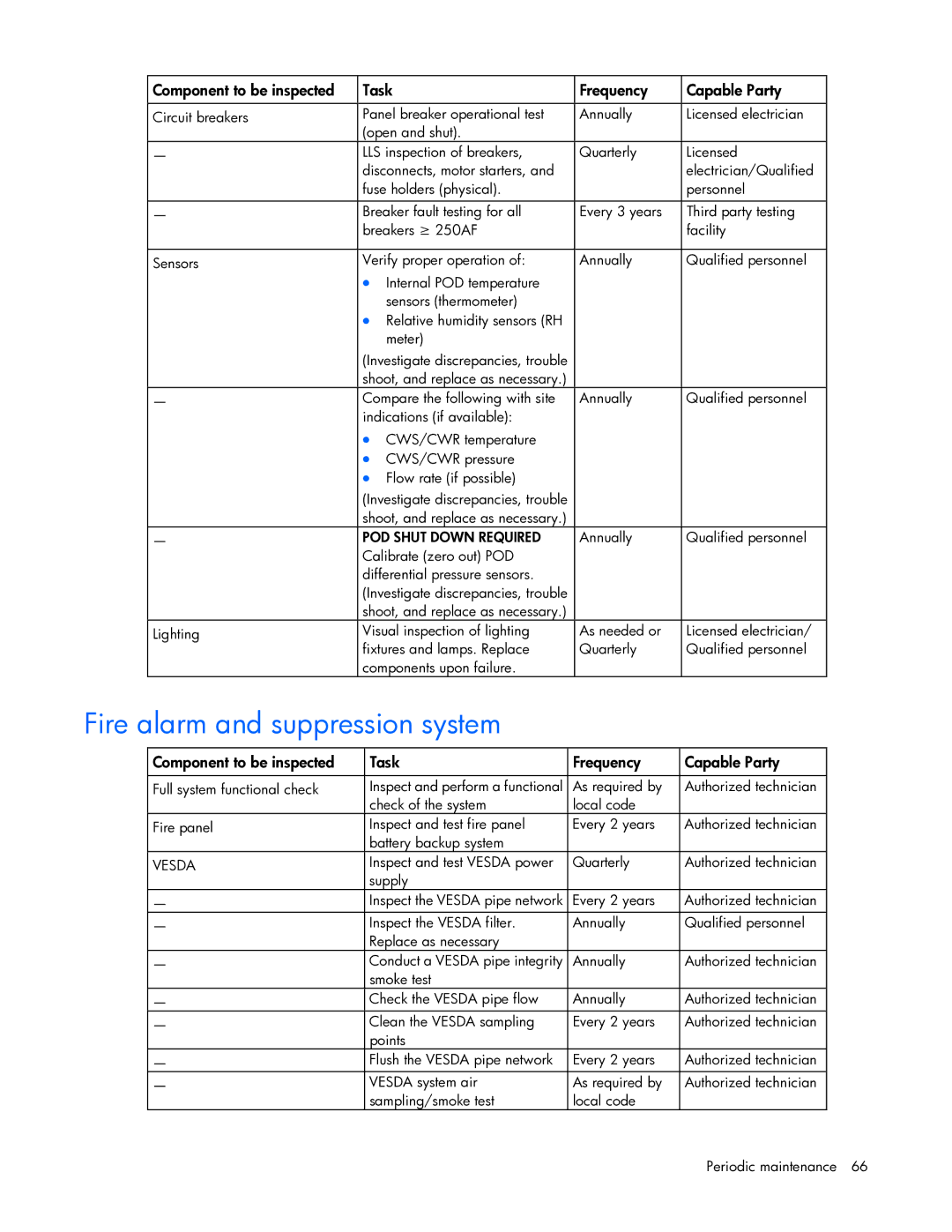

Component to be inspected | Task | Frequency | Capable Party | |

|

|

|

| |

Circuit breakers | Panel breaker operational test | Annually | Licensed electrician | |

| (open and shut). |

|

| |

— | LLS inspection of breakers, | Quarterly | Licensed | |

| disconnects, motor starters, and |

| electrician/Qualified | |

| fuse holders (physical). |

| personnel | |

|

|

|

| |

— | Breaker fault testing for all | Every 3 years | Third party testing | |

| breakers ≥ 250AF |

| facility | |

|

|

|

| |

Sensors | Verify proper operation of: | Annually | Qualified personnel | |

| • | Internal POD temperature |

|

|

|

| sensors (thermometer) |

|

|

| • Relative humidity sensors (RH |

|

| |

|

| meter) |

|

|

| (Investigate discrepancies, trouble |

|

| |

| shoot, and replace as necessary.) |

|

| |

— | Compare the following with site | Annually | Qualified personnel | |

| indications (if available): |

|

| |

| • | CWS/CWR temperature |

|

|

| • | CWS/CWR pressure |

|

|

| • Flow rate (if possible) |

|

| |

| (Investigate discrepancies, trouble |

|

| |

| shoot, and replace as necessary.) |

|

| |

— | POD SHUT DOWN REQUIRED | Annually | Qualified personnel | |

| Calibrate (zero out) POD |

|

| |

| differential pressure sensors. |

|

| |

| (Investigate discrepancies, trouble |

|

| |

| shoot, and replace as necessary.) |

|

| |

Lighting | Visual inspection of lighting | As needed or | Licensed electrician/ | |

| fixtures and lamps. Replace | Quarterly | Qualified personnel | |

| components upon failure. |

|

| |

Fire alarm and suppression system

Component to be inspected | Task | Frequency | Capable Party |

|

|

|

|

|

|

Full system functional check | Inspect and perform a functional | As required by | Authorized technician |

|

| check of the system | local code |

|

|

Fire panel | Inspect and test fire panel | Every 2 years | Authorized technician |

|

| battery backup system |

|

|

|

VESDA | Inspect and test VESDA power | Quarterly | Authorized technician |

|

| supply |

|

|

|

— | Inspect the VESDA pipe network | Every 2 years | Authorized technician |

|

— | Inspect the VESDA filter. | Annually | Qualified personnel |

|

| Replace as necessary |

|

|

|

— | Conduct a VESDA pipe integrity | Annually | Authorized technician |

|

| smoke test |

|

|

|

— | Check the VESDA pipe flow | Annually | Authorized technician |

|

— | Clean the VESDA sampling | Every 2 years | Authorized technician |

|

| points |

|

|

|

— | Flush the VESDA pipe network | Every 2 years | Authorized technician |

|

— | VESDA system air | As required by | Authorized technician |

|

| sampling/smoke test | local code |

|

|

|

|

| Periodic maintenance 66 | |