T H E O R Y O F O P E R A T I O N

Stepper motor

5

The V8.5e uses a bipolar,

5.3INTERFACE

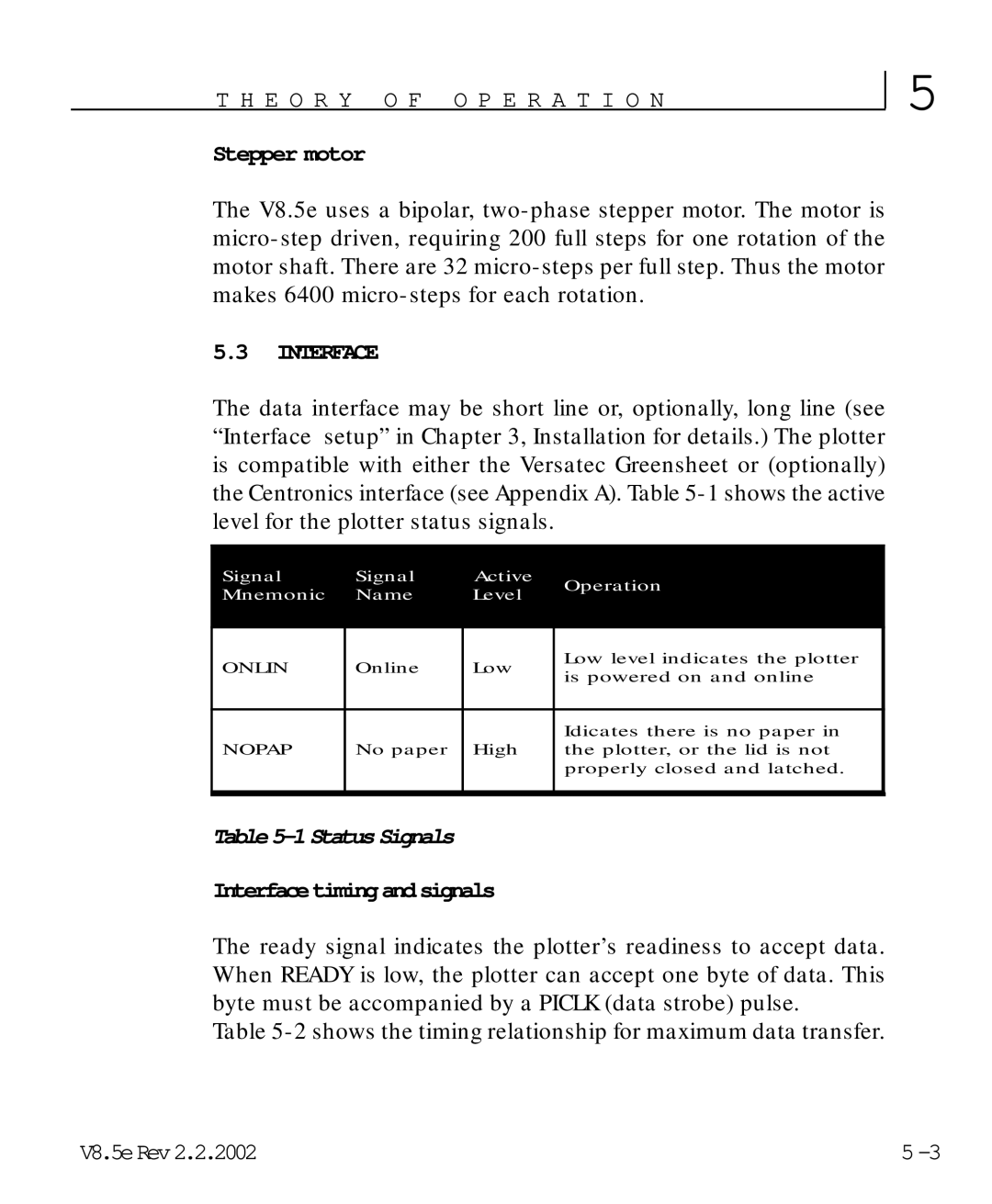

The data interface may be short line or, optionally, long line (see “Interface setup” in Chapter 3, Installation for details.) The plotter is compatible with either the Versatec Greensheet or (optionally) the Centronics interface (see Appendix A). Table

Signal | Signal | Active | Operation | |

Mnemonic | Name | Level | ||

| ||||

|

|

|

| |

ONLIN | Online | Low | Low level indicates the plotter | |

is powered on and online | ||||

|

|

| ||

|

|

|

| |

|

|

| Idicates there is no paper in | |

NOPAP | No paper | High | the plotter, or the lid is not | |

|

|

| properly closed and latched. | |

|

|

|

| |

|

|

|

|

Table 5-1 Status Signals

Interface timing and signals

The ready signal indicates the plotter’s readiness to accept data. When READY is low, the plotter can accept one byte of data. This byte must be accompanied by a PICLK (data strobe) pulse.

Table

V8.5eRev2.2.2002 | 5 |