101

Rider Pro

Operator´s manual

IMPORTANT INFORMATION

CONTENTS Operator’s Manual for Rider Pro

Safe operation practices for ride-on mowers

SAFETY INSTRUCTIONS

I. General operation

II. Slope operation

Travel and transport on public roads

IV. Service

Towing

Intended use

Dear customer

INSTRUCTION

Driving and transport on public roads

Towing

Serial number

Good service

EXPLANATION OF SYMBOLS

Read the instructions before starting the machine

General use

Clear the area from stones etc. before cutting

Never carry passengers

Driving on slopes

Be extra careful when driving on slopes

Do as follows

Cut slopes upwards and downwards, not sideways

Children

Maintenance

Keep children away from the mowing area

Never allow children to drive the machine

Clean the machine regularly from grass, leaves and other waste

Never smoke in the vicinity of the battery or the fuel

Never drive the machine in an enclosed space

Do not alter the setting of the governor and do not race the engine

PRESENTATION

Presentation

Location of the controls

Throttle control

Choke lever

Speed limiter

Cutting unit

Lift lever for cutting unit

Lifting of the cutting unit Lowering of the cutting unit

Parking brake

Lever for adjustment of the cutting height

Seat

Fuelling

DRIVING

Before starting

Starting the engine

Driving the machine

Mowing pattern

Cutting tips

Release lever

Stopping the engine

Maintenance schedule

MAINTENANCE

Maintenance

Maintenance interval in

The parking brake is applied

The engine is switched off

The ignition key is removed

The cutting unit is disengaged

Engine hood

Removing of the machine hoods

Front hood

Right-hand fender

Transmission cover

Checking and adjustment of the steering wires

Checking and adjustment of the throttle wire

Adjusting the brakes

Checking and adjusting the choke wire

Poorly adjusted brakes can result in reduced braking power

Checking of the fuel pump’s air filter

Replacement of the fuel filter

Do not use compressed air to clean the paper filter

Replacing the air filter

Do not wash the paper filter Do not oil the paper filter

Check the transmission’s air intake

Cleaning the filter

Check the engine’s cooling air intake

Muffler air intake

Procedures on contact with acid

Check the level of the battery acid

Inspecting the safety system

Checking the tyre pressure

The tyre pressure should be 60 kPa 0.6 kp/cm2 all round

The maximum tyre pressure is 80 kPa 0,8 kp/cm2

Fitting the cutting unit

Installing BioClip

Checking and adjustment of the cutting unit’s ground pressure

BioClip

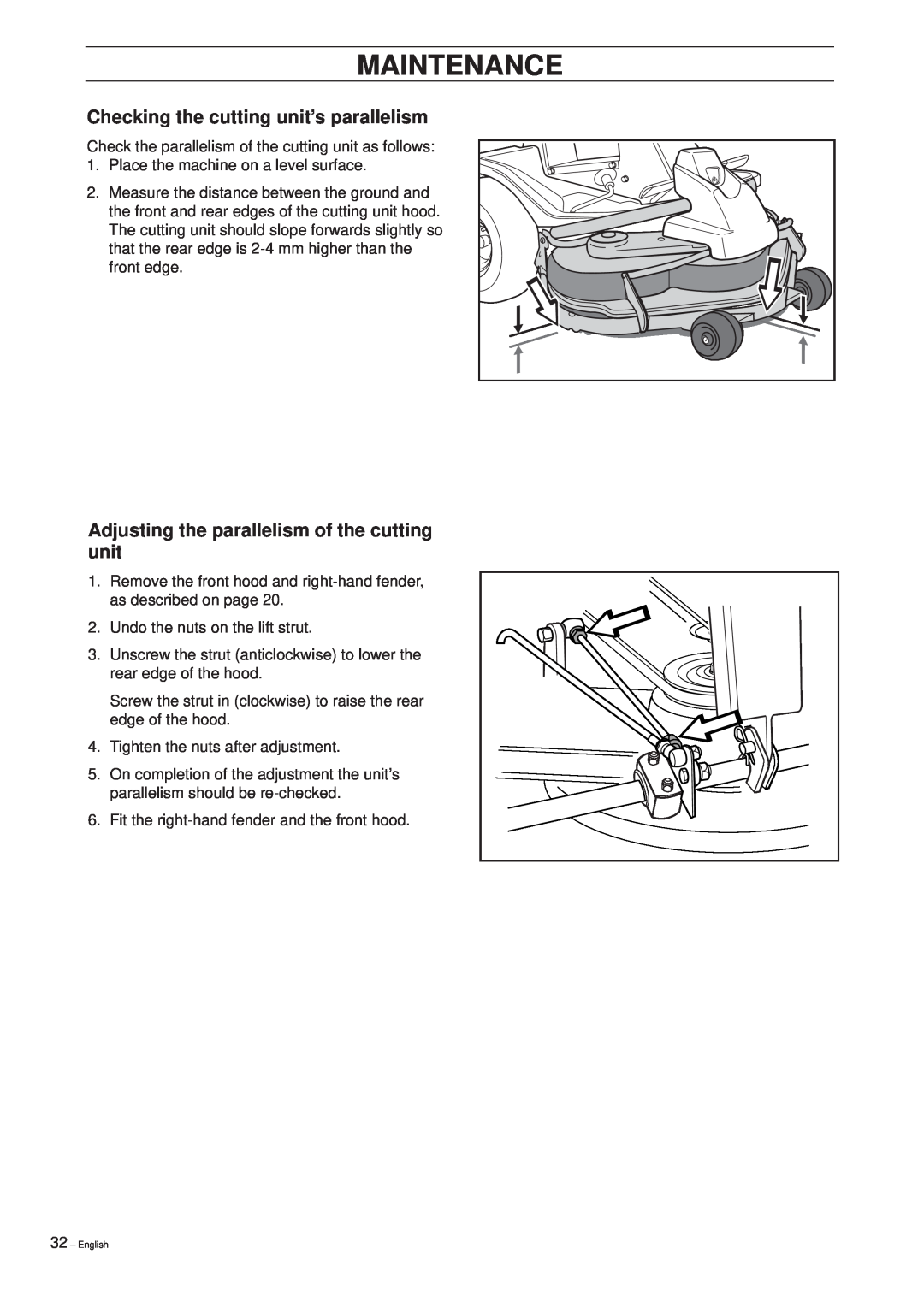

Checking the cutting unit’s parallelism

Adjusting the parallelism of the cutting unit

Removing the belt

Removing the cutting unit

Protect your hands by wearing gloves when working with the blades

Belt replacement on the BioClip

Replacing the cutting unit’s belts

BioClip 103 Versions 1 and BioClip 103 Versions 1 and

Belt replacement on cutting unit’s with side or rear ejectors

Belt replacement on BioClip

Placing in service position

Service position for cutting unit

5. Disengage the spring from the drive belt tensioning wheel

Restoring from service position

Checking the blades

Cutting units with rear ejection Cutting units with side ejection

BioClip103 BioClip

Replacing the break-pin BioClip

LUBRICATION

Lubrication chart

12/12 1/12

1/52 1/365

Lubricating wires

General

1. Cutting unit

2. Pedal mechanism in frame tunnel

3. Chains in frame tunnel

4. Triangular link and joints

6. Throttle and choke wires, lever bearings

5. Driver’s seat

7. Belt tensioner

8. Engine oil

Changing the engine oil

FULL

10. Parking brake wire

9. Gear lever

11. Transmission oil level

13. Replacing the oil filter

12. Transmission

IMPORTANT INFORMATION Dispose of used filters at a recycling station

Avoid skin contact, wash with soap and water in the event of spillage

TROUBLE SHOOTING SCHEDULE

Problem

Procedure

Service

STORAGE

Winter storage

1. Microswitch, hydrostatic transmission 2. Microswitch, cutting unit

WIRING DIAGRAM

3. Microswitch, seat 4. Ignition lock 5. Counter 6. Start relay

Explanation of colour abbreviations in wiring diagram

Rider Pro

TECHNICAL DATA

Engine

Electrical system

BioClip

EU declaration of conformity Only applies to Europe

Side ejector

Rear ejector

SERVICEJOURNAL

Pre-delivery service

Work done

54 - English

25 hour service

50 hour service

56 - English

100/200 hour service

300 hour service

58 - English

At least once a season

Date, mileage, stamp, sign

60 - English

´*3-Q¶5w¨

Page

2001W02