REPAIRS

assembly is supplied with an “O” ring (47) . The “O” ring must be removed before the pulley is fitted.

Replacing Bearings

The fitting procedure is the reverse of the removal procedure.

Tightening torques:

•Blade bolts 122 Nm (90 lb/ft).

•Pulley bolts 61 Nm (45 lb/ft).

Sharpening and Balancing Blades |

| |

| WARNING! |

|

| Blades with any cracking must |

|

| not be used. Do not straighten |

|

| a damaged blade if there is any |

|

| danger of crack formation. |

|

• | Remove the blades. |

|

• Check that the blades do not have cracks | ||

or any other damage. If they do, scrap | Grinding a blade |

them. |

|

•Clamp in a screw vice (see diagram) and file until sharp.

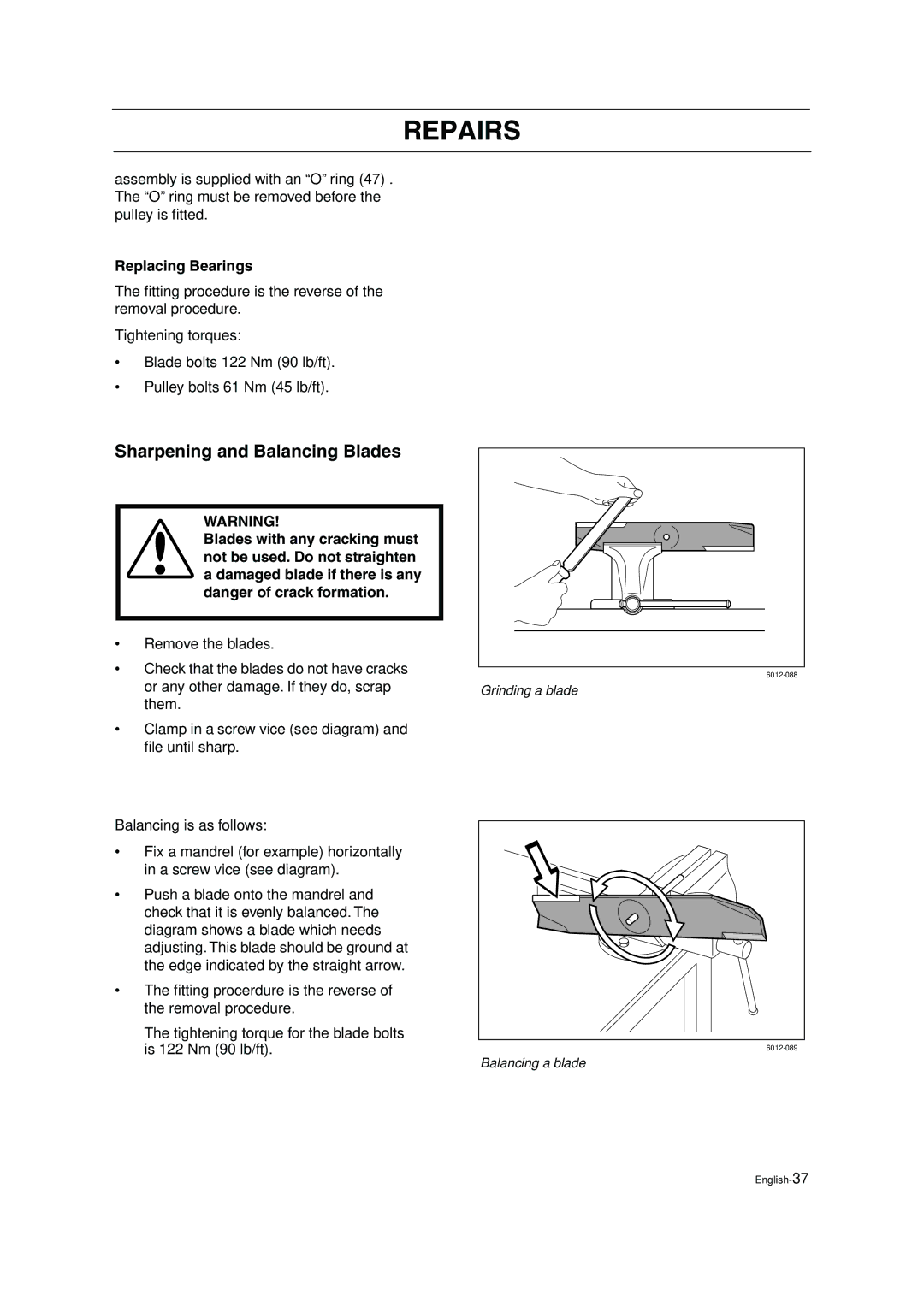

Balancing is as follows: |

|

• Fix a mandrel (for example) horizontally |

|

in a screw vice (see diagram). |

|

• Push a blade onto the mandrel and |

|

check that it is evenly balanced. The |

|

diagram shows a blade which needs |

|

adjusting. This blade should be ground at |

|

the edge indicated by the straight arrow. |

|

• The fitting procerdure is the reverse of |

|

the removal procedure. |

|

The tightening torque for the blade bolts |

|

is 122 Nm (90 lb/ft). | |

| Balancing a blade |