IRN 15 − 18.5 kW 20 − 25 HP IRN 22 − 30 kW 30 − 40 HP

AIR Compressor Group Bonded Warranty & Registered Start UP

Contents & Abbreviations

If in Doubt Consult Supervision

Foreword

Copyright Ingersoll Rand Company Limited

Decals ISO Symbols

Graphic Form and Meaning of ISO Symbols

Reset

Rotation

USE no Hooks No Side Clamps Hours Power Inspect Clean

Power Inlet AC

Decals

Change / Replace

Decals Ansi Symbols

Graphic Form and Meaning of Ansi Symbols

Decals A.N.S.I

Ccn Qty Description

Decals I.S.O

Breathing AIR Precaution

Safety

Avoid INGESTION, Skin Contact and Inhalation of Fumes

Condensate disposal

General Information

BLU Blue

RED Red

TN, TT, IT 3+N+PE −230V, 380−415V, 50Hz

TN, TT, IT 3+PE V, 60Hz

XS1

QF1

FR1

FR2

Piping and Instrumentation KEY

Installation / Handling

KEY 20−40HP 120 Gallon Baseplate

20−40HP 120 Gallon

20−40HP 240 Gallon

15−30kW 500 Litre

15−30kW 750 Litre

Dryer Installation

Unpacking

Location in the Plant

Discharge Piping

Compressor

Motor

Cooling System − Air cooled

General Data

Drive motor

IP65

Electrical Data

All data applies to standard product only

60/50Hz IRN 30HP/ 22 kW IRN 40HP / 30 kW

150A 125A 75A 70A

Be changed during installation

Outdoor Modification Option

Operating Instructions

General Operation

Do not direct the airflow at face or eyes

LOW Demand Applications

STOP/RESET KEY

Dewpoint Indicator Dryer only

Emergency Stop

Start KEY

Dewpoint Adjustment Dryer only

Setup Screen

Status Display

Status Display

VFD/FIXED Mode

Energy Savings Reset

Target Pressure

PSI

Service Screen

Alarms

Period Maintenance

Maintenance

Routine Maintenance

TOP UP Coolant Procedure

Coolant Change Procedure

Coolant Filter Change Procedure

AIR Filter Element Change Procedure

Maintenance

Recycling Disassembly

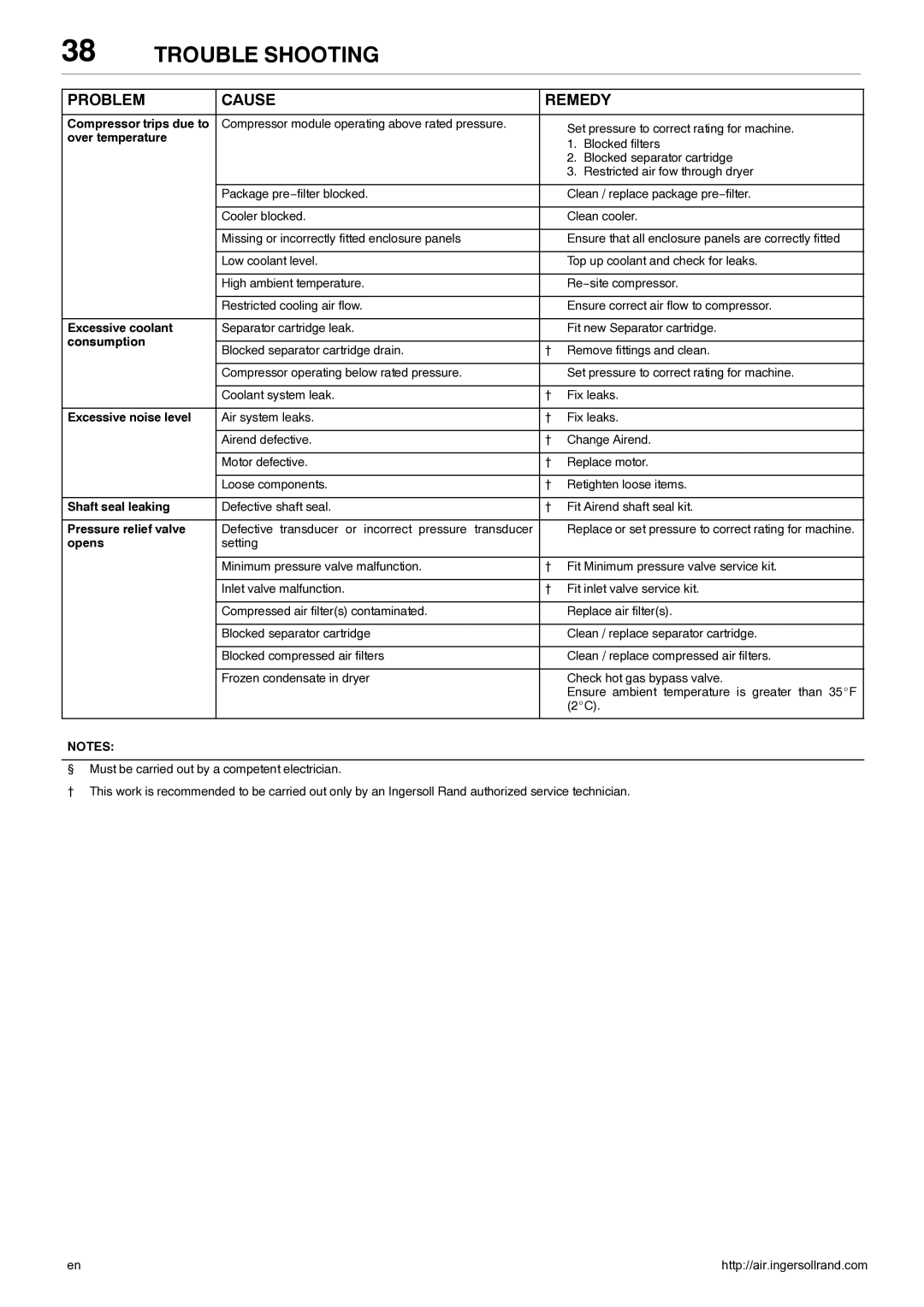

Trouble Shooting

Problem Cause Remedy

Over temperature

Excessive coolant

Consumption

Excessive noise level

Page

Page

Manuel D’UTILISATION ET D’ENTRETIEN

Garantie

Contenu & Abreviations

EN CAS DE DOUTE, REFEREZ−VOUS a Votre Superviseur

AVANT−PROPOS

Tableau

Decals Symboles ISO

Structure Graphique ET Signification DES Symboles ISO

Sous pression ’air

Recalage

Puissance Controler

Changer / Remplacer Nettoyer Prise D’ALIMENTATION AC

Decals Symboles Ansi

Structure Graphique ET Signification DES Symboles Ansi

Article Nic Quantité Description

Fixation sur base uniquement

Precautions

Precautions Contre L’UTILISATION Pour LA Respiration

Securite

Avertissement

Electricité

Mise au rebut du condensat

Lexique

Informations Générales

Fils

TN, TT, IT 3+PE −230V, 60Hz −460V, 50Hz/60Hz

TN, TT, IT 3+N+PE −230V, 380−415V, 50Hz

TN, TT, IT 3+PE V, 60Hz

TN, TT, IT 3+PE −230V, 60Hz −460V, 50Hz

Tuyauteries ET Instrumentation Lexique

Installation / Manutention

20−40 HP Banc 120 Gallon

20−40 HP 120 Gallon

20−40 HP 240 Gallon

15−30 KW 500 Litres

15−30 KW 750 Litres

Installation DU Sécheur

Desemballage

Localisation Dans L’USINE

Precaution

Tuyauterie DE Refoulement

Moteur

Compresseur

Donnees Generales

Specifications Electriques

Moteur d’entraînement

Puissance nominale 30HP / 22kW 40HP / 30kW Bobinage F

Puissance 20HP / 15kW Courant à pleine charge Maximum Cycles

Electricite

Option DE Modification À L’AIR Libre

Generalites

Instructions DE Marche

Ne pas diriger le débit d’air vers la figure ou les yeux

Arrêt D’URGENCE

Touche DE Demarrage

Touches DE Navigation

Touches D’AFFICHAGE Touche D’INFORMATION

Affichage d’état

Affichage D’ETAT

Ecran DE Reglage

Mode D’ENTRAINEMENT a Frequence Variable VFD / Vitesse Fixe

Pression Ciblée

Pression D’ARRET Automatique

MARCHE/ARRET Programme

Alarmes

Ecran DE Service

Avertissements

Période Maintenance

Maintenance DE Routine

Procedure D’EMPLISSAGE DU Produit DE Refroidissement

Procedure DE Vidange DU Liquide DE Refroidissement

Procedure DE Changement DU Filtre a Coolant

Procedure DE Changement DE L’ELEMENT Filtrant

Procedure DE Changement DE LA Cartouche DE Separation

Procedure DE Nettoyage DU Radiateur

Robinet DE Purge Electrique Description DU Produit

Reglage DE LA Minuterie

Fonctionnement

Entretien DU Filtre a AIR

Desassemblage DE LA Machine

Fuites DE Refrigerant Dans LE Circuit DE Refrigeration

Chargement DU Refrigerant

Recherche DE Pannes Raison Action

Maintenance

Defaut Cause Solution

Recherche DE Défauts

Déclenchements du

Compresseur dus aux

Surchauffes

Consommation

Page

REV Data

Grupo Compressor DE AR Garantia Formal E Arranque Registado

Garantia

Índice & Abreviaturas

SE Tiver Dúvidas Consulte O Encarregado

Introdução

Tabla

Configuração Gráfica E Significado DOS Símbolos ISO

Autocolante Símbolos ISO

Rearme

Rotação Descarga AR Filtro DEL Refrigerante

Autocolante

NÃO USE Ganchos

Horas Tensão Inspeccionar

Mudar / Substituir

Configuração Gráfica E Significado DOS Símbolos Ansi

Autocolante Símbolos Ansi

Autocolantes A.N.S.I

Ccn Qtd Descrição

Autocolantes I.S.O

Segurança

Electricidade

Eliminação de condensado

Chave

Informação Geral

Fios

BLU Azul

TN, TT, IT 3+N+PE −230V, 380−415V, 50Hz

TN, TT, IT 3+PE V, 60Hz

P1, P2 Transdutor da pressão Opção do secado Alarme comum

Principais terminais

Motor de arranque da ventoinha

Relé do estado sólido

Tubagem E Instrumentação Chave

Instalação / Manuseamento

20−40 HP Cilindro 120 Galão

20−40 HP 120 Galão

20−40 HP 240 Galão

15−30 KW 500 Litros

15−30 KW 750 Litros

Desambalamento

Nota

Instalação do Secador

Instalação

Precaução

Cuidado

Tubagem DE Descarga

Sistema DE Arrefecimento − Arrefecido a ar

Dados Gerais

Dados Eléctricos

Motor de accionamento

Todos este dados dizem respeito somente a produto de série

60/50Hz IRN 30HP/ 22 kW IRN 40HP / 30 kW

150A 125A 75A 70A

Opção DE Modificação AO AR Livre

Instruções DE Operação

Funcionamento Geral

Aviso

Cuidado Aplicações DE Baixa Potência

Paragem DE Emergência

Tecla DE Activação

Tecla DE DESACTIVAÇÃO/REINICIALIZAÇÃO

Teclas DE Navegação

Ecrã DE Configuração

Ajuste do Ponto DE Condensação Apenas Para O Secador

Ecrã do Estado

Ecrã do Estado

Pressâo Alvo

Pressão DA Desactivação Automática

Modo VFD/FIXO

ACTIVAÇÃO/DESACTIVAÇÃO Programada

Ecrã DE Assistência

Avisos

Período Manutenção

Manutenção

Conservação DE Rotina

Procedimento Para Atestar O Refrigerante

Procedimento Para a Mudança DE Refrigerante

Procedimento Para Mudança do Filtro DE Refrigerante

Procedimento Para Substituição do Elemento do Filtro DE AR

Regulação do Transdutor DE Pressão PT

Procedimento DE Limpeza do Arrefecedor

Electroválvula DE Drenagem

Para Verificar a Pressão Pretendida

Manutenção do Filtro DE AR

Regulações do Temporizador

Desmontagem DA Unidade

Solução DE Problemas Causa Acção

Fugas DE Refrigerante no Circuito DE Refrigeração

Carregamento COM Refrigerante

Manutenção

Diagnóstico DE Avarias

Avaria Causa Solução

Compressor dispara

Devido a temperatura

Alta

Consumo elevado de

Page

REV Fecha

Grupo DE Compresores DE Aire Garantia Y Arranque Registrado

Contenido & Abreviaturas

Preambulo

SI Tiene Dudas Consulte AL Supervisor

Forma Grafica Y Significado DE LOS Simbolos ISO

Calcomanias Simbolos ISO

Reposicionar

Calcomanias

Energia Electrica Inspeccionar

Riesgo de punto de aplastamiento Mantener las manos alejadas

Calcomanias Simbolos Ansi

Forma Grafica Y Significado DE LOS Simbolos Ansi

Calcomanias A.N.S.I

Elemento ccn Cantidad Descripción

Calcomanias I.S.O

Seguridad

Advertencia

Sistema eléctrico

Eliminación del condensado

Informacion General

Clave XS1

FU3

Cables

BRO Marrón WHT Blanco

TN, TT, IT 3+N+PE −230V, 380−415V, 50Hz

FU4 Fusibles del secador

Clave

Conductos E Instrumentacion Clave

Instalación / Manejo

Clave 20−40 HP Bancada 120 Galón

20−40 HP 120 Galón

20−40 HP 240 Galón

15−30 KW 500 Litros

15−30 KW 750 Litros

Desembalaje

Instalación DEL Secador

Ubicacion EN LA Planta

Precaucion

Precaución

Tuberia DE Descarga

Refrigerador − Refrigeración por aire

Compresor

Datos Generales

Datos Electricos

Potencia nominal 30HP / 22kW 40HP / 30kW Arrollamiento

150A 125A 75A 70A

Caracteristicas Electricas

Opción DE Modificación AL Aire Libre

Funcionamiento General

Instrucciones DE Operacion

Precaución Aplicaciones DE Baja Demanda

Emergency Stop Parada DE Emergencia

Tecla Start Arranque

Teclas DE Navegación

Teclas DE Visualización Información KEY

Visualización DE Estado

Visualización de Estado

Viualización de Estado

Pantalla DE Ajuste

Presión Deseada

Presión DE Parada Automática

Modo VFD / Fijo

Arranque / Parada Programado

Pantalla DE Servicio

Alarmas

Advertencias

Mantenimiento

Período Mantenimiento

Condensador

Mantenimiento DE Rutina

Procedimiento Para Restablecer EL Nivel DEL Refrigerante

Procedimiento DE Cambio DEL Refrigerante

Procedimiento DE Cambio DEL Filtro DE Refrigerante

Procedimiento DE Cambio DEL Elemento DEL Filtro

Procedimiento DE Cambio DEL Cartucho DEL Separador

Procedimiento DE Limpieza DEL Refrigerador

Valvula Electrica DE Vaciado

Ajuste DEL Transductor DE Presion PT

Mantenimiento DEL Filtro DE Aire

Ajustes DEL Temporizador

Desmontaje DE LA Unidad

Fugas DE Refrigerante EN EL Circuito DE Refrigeracion

Carga DE Refrigerante

Localizacion DE Fallos Causa Accion

Mantenimiento

Resolucion DE Averias

Averia Causa Remedio

Debido a temperatura

Excesiva

Consumo excesivo de

Se abre la válvula de