SAFETY INSPECTION/TROUBLESHOOTING | PROCEDURE 2 |

|

|

This Procedure Includes the Following: |

|

Safety Inspection Checklist | Checking Battery Charge Level |

Troubleshooting - Mechanical |

|

Troubleshooting - Electrical |

|

|

|

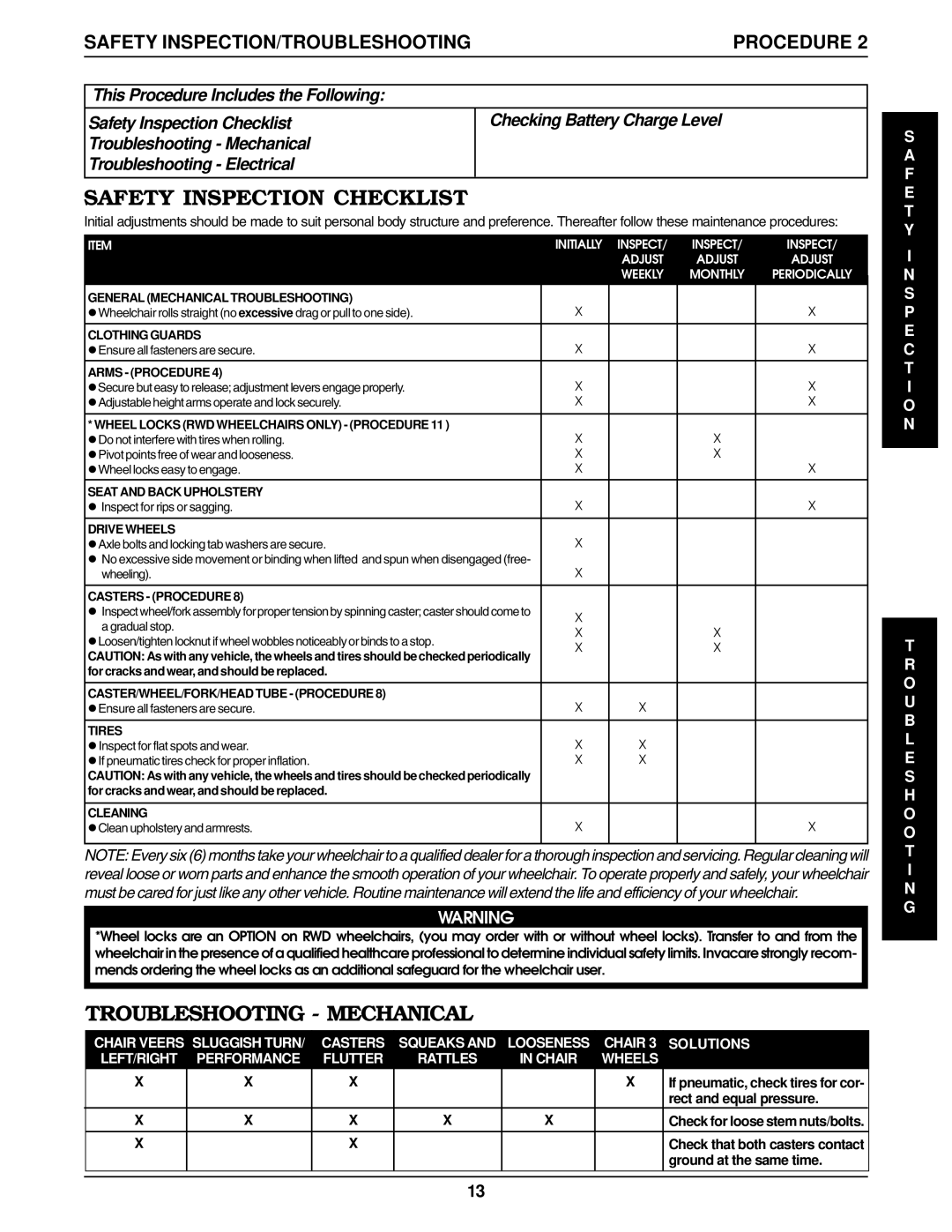

SAFETY INSPECTION CHECKLIST

Initial adjustments should be made to suit personal body structure and preference. Thereafter follow these maintenance procedures:

ITEM | INITIALLY | INSPECT/ | INSPECT/ | INSPECT/ |

|

| ADJUST | ADJUST | ADJUST |

|

| WEEKLY | MONTHLY | PERIODICALLY |

|

| |||

|

|

|

|

|

GENERAL (MECHANICAL TROUBLESHOOTING) | X |

|

| X |

lWheelchair rolls straight (no excessive drag or pull to one side). |

|

| ||

|

|

|

|

|

CLOTHING GUARDS | X |

|

| X |

lEnsure all fasteners are secure. |

|

| ||

|

|

|

|

|

ARMS - (PROCEDURE 4) | X |

|

| X |

lSecure but easy to release; adjustment levers engage properly. |

|

| ||

lAdjustable height arms operate and lock securely. | X |

|

| X |

|

|

|

|

|

* WHEEL LOCKS (RWD WHEELCHAIRS ONLY) - (PROCEDURE 11 ) | X |

| X |

|

lDo not interfere with tires when rolling. |

|

| ||

lPivot points free of wear and looseness. | X |

| X |

|

lWheel locks easy to engage. | X |

|

| X |

|

|

|

|

|

SEAT AND BACK UPHOLSTERY | X |

|

| X |

l Inspect for rips or sagging. |

|

| ||

|

|

|

|

|

DRIVE WHEELS | X |

|

|

|

lAxle bolts and locking tab washers are secure. |

|

|

| |

l No excessive side movement or binding when lifted and spun when disengaged (free- | X |

|

|

|

wheeling). |

|

|

| |

|

|

|

|

|

CASTERS - (PROCEDURE 8) |

|

|

|

|

l Inspect wheel/fork assembly for proper tension by spinning caster; caster should come to | X |

|

|

|

a gradual stop. |

|

|

| |

X |

| X |

| |

lLoosen/tighten locknut if wheel wobbles noticeably or binds to a stop. |

|

| ||

X |

| X |

| |

CAUTION: As with any vehicle, the wheels and tires should be checked periodically |

|

| ||

|

|

|

| |

for cracks and wear, and should be replaced. |

|

|

|

|

|

|

|

|

|

CASTER/WHEEL/FORK/HEAD TUBE - (PROCEDURE 8) | X | X |

|

|

lEnsure all fasteners are secure. |

|

| ||

|

|

|

|

|

TIRES | X | X |

|

|

lInspect for flat spots and wear. |

|

| ||

lIf pneumatic tires check for proper inflation. | X | X |

|

|

CAUTION: As with any vehicle, the wheels and tires should be checked periodically |

|

|

|

|

for cracks and wear, and should be replaced. |

|

|

|

|

|

|

|

|

|

CLEANING | X |

|

| X |

lClean upholstery and armrests. |

|

| ||

|

|

|

|

|

NOTE: Every six (6) months take your wheelchair to a qualified dealer for a thorough inspection and servicing. Regular cleaning will reveal loose or worn parts and enhance the smooth operation of your wheelchair. To operate properly and safely, your wheelchair must be cared for just like any other vehicle. Routine maintenance will extend the life and efficiency of your wheelchair.

WARNING

*Wheel locks are an OPTION on RWD wheelchairs, (you may order with or without wheel locks). Transfer to and from the wheelchair in the presence of a qualified healthcare professional to determine individual safety limits. Invacare strongly recom- mends ordering the wheel locks as an additional safeguard for the wheelchair user.

TROUBLESHOOTING - MECHANICAL

CHAIR VEERS | SLUGGISH TURN/ | CASTERS | SQUEAKS AND | LOOSENESS | CHAIR 3 | SOLUTIONS |

LEFT/RIGHT | PERFORMANCE | FLUTTER | RATTLES | IN CHAIR | WHEELS |

|

X | X | X |

|

| X | If pneumatic, check tires for cor- |

|

|

|

|

|

| rect and equal pressure. |

X | X | X | X | X |

| Check for loose stem nuts/bolts. |

X |

| X |

|

|

| Check that both casters contact |

|

|

|

|

|

| ground at the same time. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

S A F E T Y

I

N S P E C T I O N

T R O U B L E S H O O T I N G

13