Sears OwnersManual

Important Safety Instructions

Instrucciones DE Seguridad Importantes

Importantes Consignes DE SI=CURITI

Full 90-DAY Warranty On ALL Parts and Mechanical Adjustments

Machine Specifications

Especificaciones de la mdquina

Caract6ristiques de la machine

DI ,o,t,n,=LjOIIO

Indice

Rll Ko-,nnuI,,€l-Jl

LollnLeJIllr-,11-r,, l/leo81

Iu,vJIi i oll II nxI a li-1ll

Portable Case or Cabinet

Names of Parts

Nombre de las partes

Identification des pices

Pdale de contr61e

Available Accessories and Attachments

1718192O May be ordered per instructions above

Accessoires disponibles

Accesorios y refacciones disponibles

Connecting Machine to Power Supply

Power switch Machine socket Light bulb

Controlling Sewing Speed

Instrucoiones para la operaci6n

Conexi6n de la mbquina a la red elctrica

Para su seguridad

Control de la velocidad de costura

Pressure Adjusting Lever

Presser Foot Lifter

Thread Cutter

Cortahilos

Ajuste de la presibn del prensatelas

Palanca de elevaci6n del prensatelas

Estuche de accesorios

To Remove and Attach the Foot Holder

To Remove and Attach Presser Feet

Changing Needle

Cbmo quitar/poner el enmangue del prensatelas

Retrait et installation du support de pied

C6mo cambiar la aguja

Changer Iaiguille

Presser Foot Types

Pie para ojales corredizo Pie J

Tipos de pie prensatelas Pie para zig-zag Pie a

Pie para puntada recta Pie H

Pie pars cremalleras Pie E

Quilter

Pie para Ojal autombtico Pied & boutonniere automatique

Utilisez

Guia de acolchado Guide b matelasser

Selecting Needle and Thread

Lace

Malla Universal

Seleccibn de aguja e hilo

Muy Iigera Gasa, Gasa delgada

Bafiador, Tricot

Choix de Iaiguille et du fil

Poids Tissu Type daiguille Diamtre Daiguille

Blankpage pginablanca pageblanche

Horizontal Spool Pin

Large spool holder Small spool holder

Additional Spool Pin

Remplir la canette Porte-bobine horizontal

Bobbin Winding

Bobinado de la canilla

Remptir la canette

Threading chart

Removing the Hook Cover Plate

Esquema de enhebrado

Insertion de la canette

Threading the Machine

Threading the Machine

Drawing up Bobbin Thread

Extracci6n del hilo de la canilla

Enhebrado del hilo de la aguja

Enfilage de la machine

Comment faire monter le fil de la canette

Adjust the Needle Thread Tension for Straight Stitch

Tension is too loose

El hilo est=demasiado tenso

El hilo estd demasiado flojo

Si la tension est trop 61ev6e

Adjust the Needle Thread Tension for Zigzag Stitch

Correct tension

Tension correcte Endroitdu tissu Envers du tissu

Tensi6n correcta

El hilo estd demasiado tenso

Si la tension est trop faible

Stitch Selector how to select stitches

Zones

Puntadas

Selector de puntada cbmo seleccionar de

Sdlecteur de point comment choisir des points

Stitch Width control how to adjust the stitch F

Stitch Length Control how to adjust the stitch length

Indicating mark

Marca indicativa

Adjusting Stretch Stitch Balance

Reverse Stitch Control

Equilibrio de los patrones distorsionados

Signo + Pour corriger un motif dform6

Control de puntada invertida Bouton de marche arrire

Use the Quilter Guide

Straight Stitch

Use the Seam Guide

Starting to Sew

Puntada Recta

Topstitching

Quilting

SurpiqOre

Costura La vista

Acolchado

Matelassage

To Snap on the Zipper Foot

Zipper Sewing

Width

Fabric Preparation

La couture des fermetures & glissire

Costura Cremalleras

Cbmo colocar el pie para cremalleras

Pour fixer le pied fermeture & glissire

Zipper Sewing

Costura de cremalleras continuacibn

La couture des fermetures & glissire Suite

To Raise or Drop the Feed Dogs

Darning

C6mo bajar / subir los dientes del transporte

Comment monter ou descendre les griffes dentratnement

Reprisage

Basic Zigzag

Satin Stitch

Stitch width

Puntada de Satin

Puntada Zig-zag

Zig-zag simple

Point Lanc

Needle

Monogramming

Applique

Stitch foot

Monogramas

Monogrammes

Bar Tacking

Embroidery

Brides De renfort

Puntada de Refuerzo

Bordado

Broderie

Button Sewing

Overcasting Stitch

Puntada de sobrehilado o remate

Cosido de botones

Pose Des boutons

Surfilage

Blind Hem Stitch

Changing Needle Position

DobladUlo invisible Ourlet

C6mo cambiar la posicibn de la aguja

Changer la position de Iaiguille

LaceWork

Multiple Zigzag Stitch

Point zig-zag multiple

Trabajos con lazos Dentelle

Puntada de m,ltiple zig-zag

Nota Tenga cuidado de no cortar las puntadas

Shell Stitch

Box Stitch

Point De crdneau

Puntada Forma Concha Point Coquille

Puntadas De caja

Para unirlos

Fagoting Stitch

Two-point Shell Stitch

Two-point Box Stitch

Puntada para deshilachados

Decorative Stitch of Geometric Patterns

Presser foot a Zigzag foot

Puntadas decorativas de diseSos geomdtricos

Point de bordure

Puntada Para Rebordados

Points d6coratifs g6omtriques

Straight Stretch

Rick-rack Stretch

Extensibn de Rick-rackzig-zag

Extensibn

Point Droit Extensible

Croquet Extensible

Smocking

Stitch width Stitch length

Puntada elbstica de remate o sobrehilado

Surfilage Extensible

Point Smocks

Elastic Stretch Stitch

Stretch Patching

Remiendos Elbsticos

Puntada De dobladillo

Point De surjet

Point Rapi6cer Extensible

Herringbone Stretch

Gold stretch stitch position

2to

Puntada De espiga eldstica

LoTl€o l r..,YIBivlVJll lqqHl= F.ila41t

Manual Buttonhole

Ojal manual Boutonniere manuelle

Page

Ojal manual continuaci6n

How to Adjust Buttonhole Stitch Balance

C6mo equilibrar las puntadas de los ojales

Comment dcluilibrerles points pour les boutonnires

Automatic Buttonhole

Remarque Les boutonnieres reprsentdes sur

Boutonniere automatique

Plantilla

Gabarits sont grandeur nature, Vous

Width Length

Ojal Automdtico Continuacibn Boutonniere Automatique Suite

Para coser Pour coudre

Automatic Buttonhole

Ojal automdtico continuaci6n

Boutonniere automatique suite

Length

Ojal automdtico continuacibn

Boutonnibre automatique suite

Presser foot Zigzag foot Satin stitch foot Needle

Optional item

Posicibnoro de puntada

Eldsticao zone verde

Cleaning the Bobbin Holder

Replacing the Light Bulb

D6branchez la machine

Remplacement de rampoule

Cambiando la bombilla

Limpiando el portacanillas Nettoyage du porte-canette

Cleaning the Hook Race and Feed Dogs

Oiling the Machine

Engrasando la mdquina

Limpieza del garfio y los dientes del transporte

Griffesdentranement Pistedu crochet

Coser Lubrification de la machine

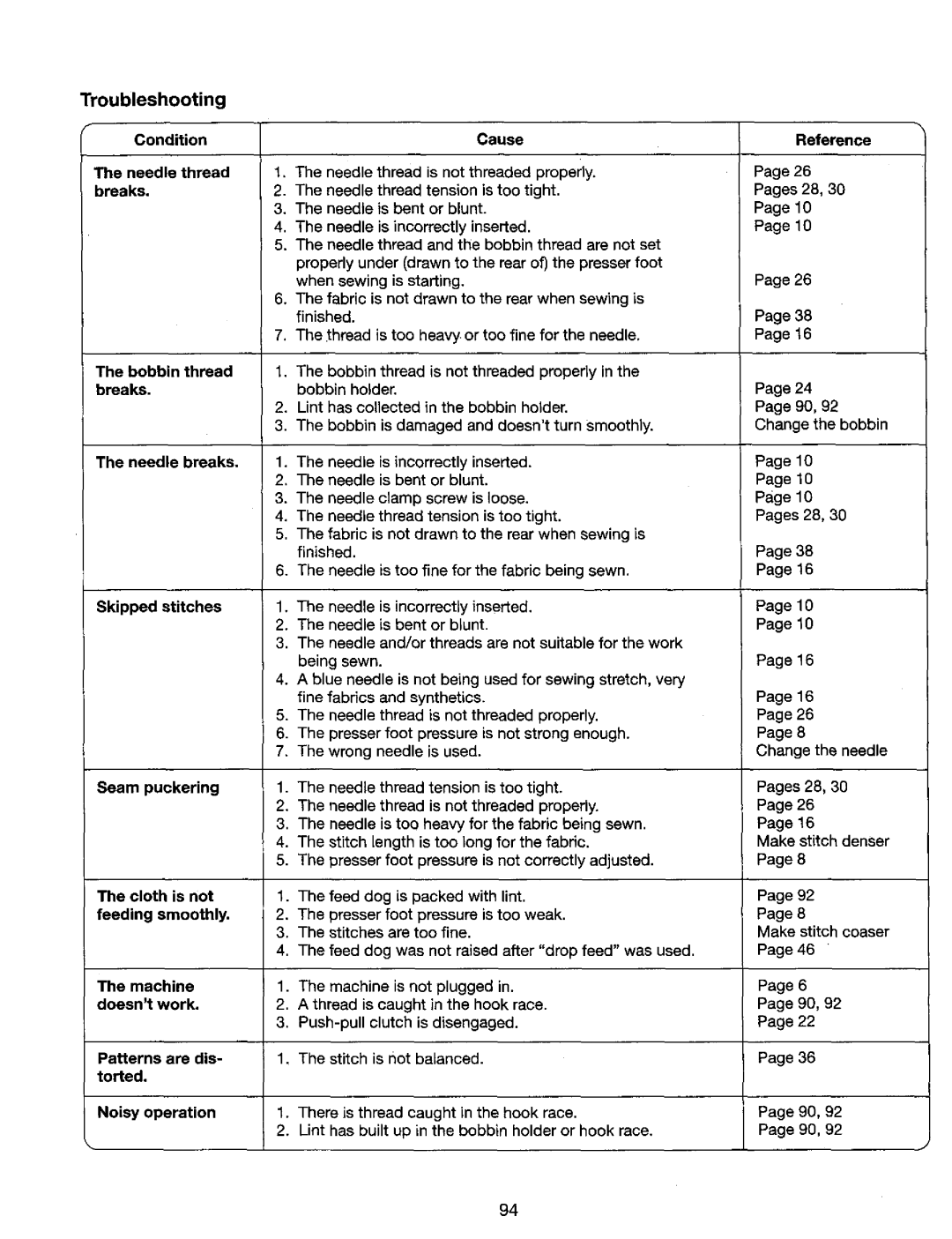

Troubleshooting

Oluciones de problemas de funcionamiento

Se rompe el hilo de la

Canilla

En cas de problbme

Probl.me Cause De rf6rence Le fil daiguille se

Sewing Machine

Sears Canada Inc., Toronto, Ont., M5B 2B8