4.If ports are clogged, clean with a straight pin. Do not enlarge or distort port. Do not leave anything stuck in the ports when replacing black porcelain burner base.

5.After cleaning the orifice opening and ports, replace the burner cap. Make sure cap is set straight on burner and that the tabs on cap fit into the grooves of burner base.

6.Check the burner for proper lighting after cleaning.

Note: If a gas burner burns with an uneven orange flame, reposition the burner cap so it sits flat on the burner housing. If burner lights slowly, have your gas service person check the gas pressure to the appliance.

If a top burner flame has been adjusted too low, the electronic ignitor may start to spark. Readjust flame until ignitor stops sparking.

When cleaning around the surface burner, use care. If cleaning cloth should catch the ignitor, it could damage it, preventing ignition.

If surface burner does not light, check if ignitor is broken, soiled or wet. If clogged, clean the small port beneath the ignitor using a straight pin.

Wipe acid or sugar spills as soon as the cooktop has cooled as these spills will discolor the porcelain.

See Cleaning Guide – Page 31.

Oven Venting - gas top models

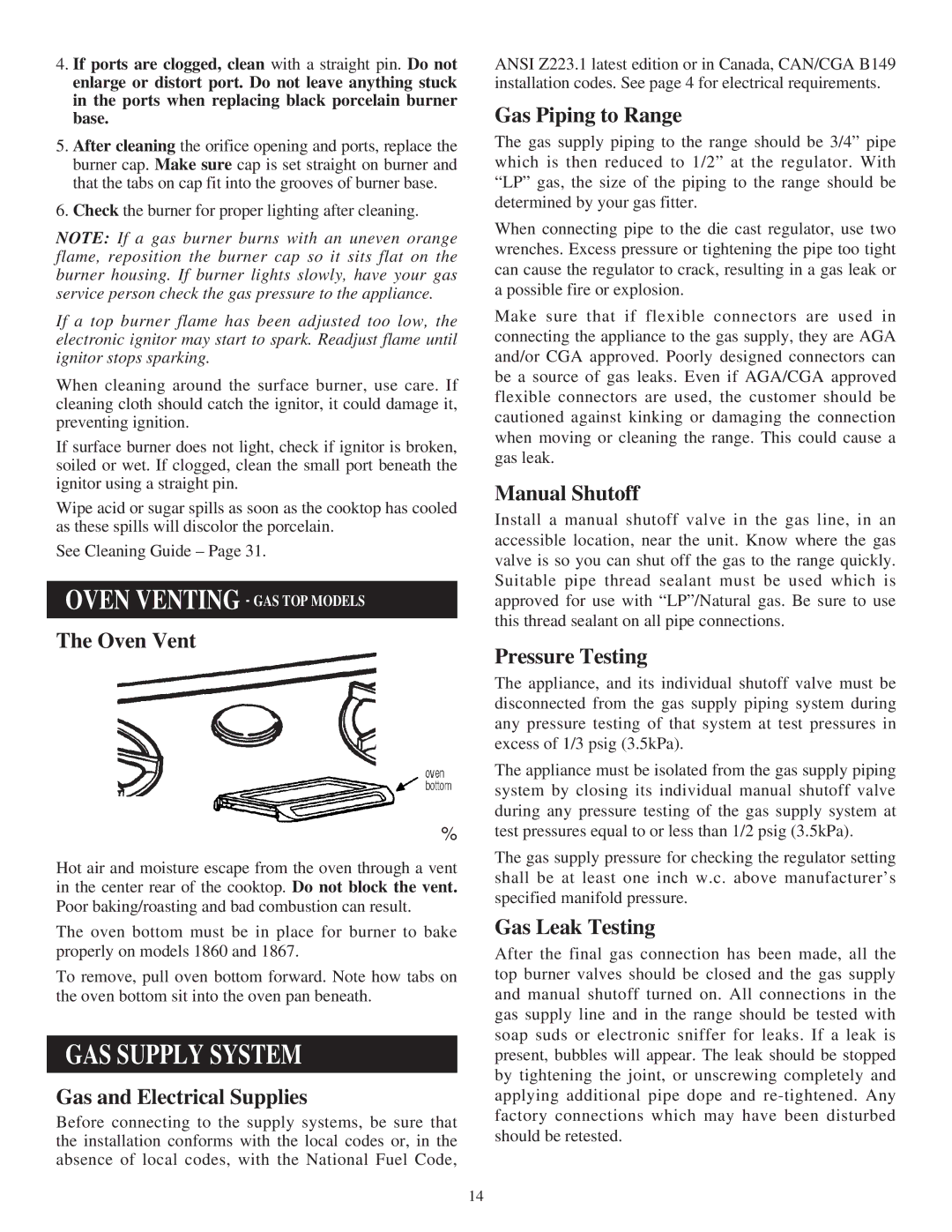

The Oven Vent

%

Hot air and moisture escape from the oven through a vent in the center rear of the cooktop. Do not block the vent. Poor baking/roasting and bad combustion can result.

The oven bottom must be in place for burner to bake properly on models 1860 and 1867.

To remove, pull oven bottom forward. Note how tabs on the oven bottom sit into the oven pan beneath.

Gas Supply System

Gas and Electrical Supplies

Before connecting to the supply systems, be sure that the installation conforms with the local codes or, in the absence of local codes, with the National Fuel Code,

ANSI Z223.1 latest edition or in Canada, CAN/CGA B149 installation codes. See page 4 for electrical requirements.

Gas Piping to Range

The gas supply piping to the range should be 3/4” pipe which is then reduced to 1/2” at the regulator. With “LP” gas, the size of the piping to the range should be determined by your gas fitter.

When connecting pipe to the die cast regulator, use two wrenches. Excess pressure or tightening the pipe too tight can cause the regulator to crack, resulting in a gas leak or a possible fire or explosion.

Make sure that if flexible connectors are used in connecting the appliance to the gas supply, they are AGA and/or CGA approved. Poorly designed connectors can be a source of gas leaks. Even if AGA/CGA approved flexible connectors are used, the customer should be cautioned against kinking or damaging the connection when moving or cleaning the range. This could cause a gas leak.

Manual Shutoff

Install a manual shutoff valve in the gas line, in an accessible location, near the unit. Know where the gas valve is so you can shut off the gas to the range quickly. Suitable pipe thread sealant must be used which is approved for use with “LP”/Natural gas. Be sure to use this thread sealant on all pipe connections.

Pressure Testing

The appliance, and its individual shutoff valve must be disconnected from the gas supply piping system during any pressure testing of that system at test pressures in excess of 1/3 psig (3.5kPa).

The appliance must be isolated from the gas supply piping system by closing its individual manual shutoff valve during any pressure testing of the gas supply system at test pressures equal to or less than 1/2 psig (3.5kPa).

The gas supply pressure for checking the regulator setting shall be at least one inch w.c. above manufacturer’s specified manifold pressure.

Gas Leak Testing

After the final gas connection has been made, all the top burner valves should be closed and the gas supply and manual shutoff turned on. All connections in the gas supply line and in the range should be tested with soap suds or electronic sniffer for leaks. If a leak is present, bubbles will appear. The leak should be stopped by tightening the joint, or unscrewing completely and applying additional pipe dope and

14