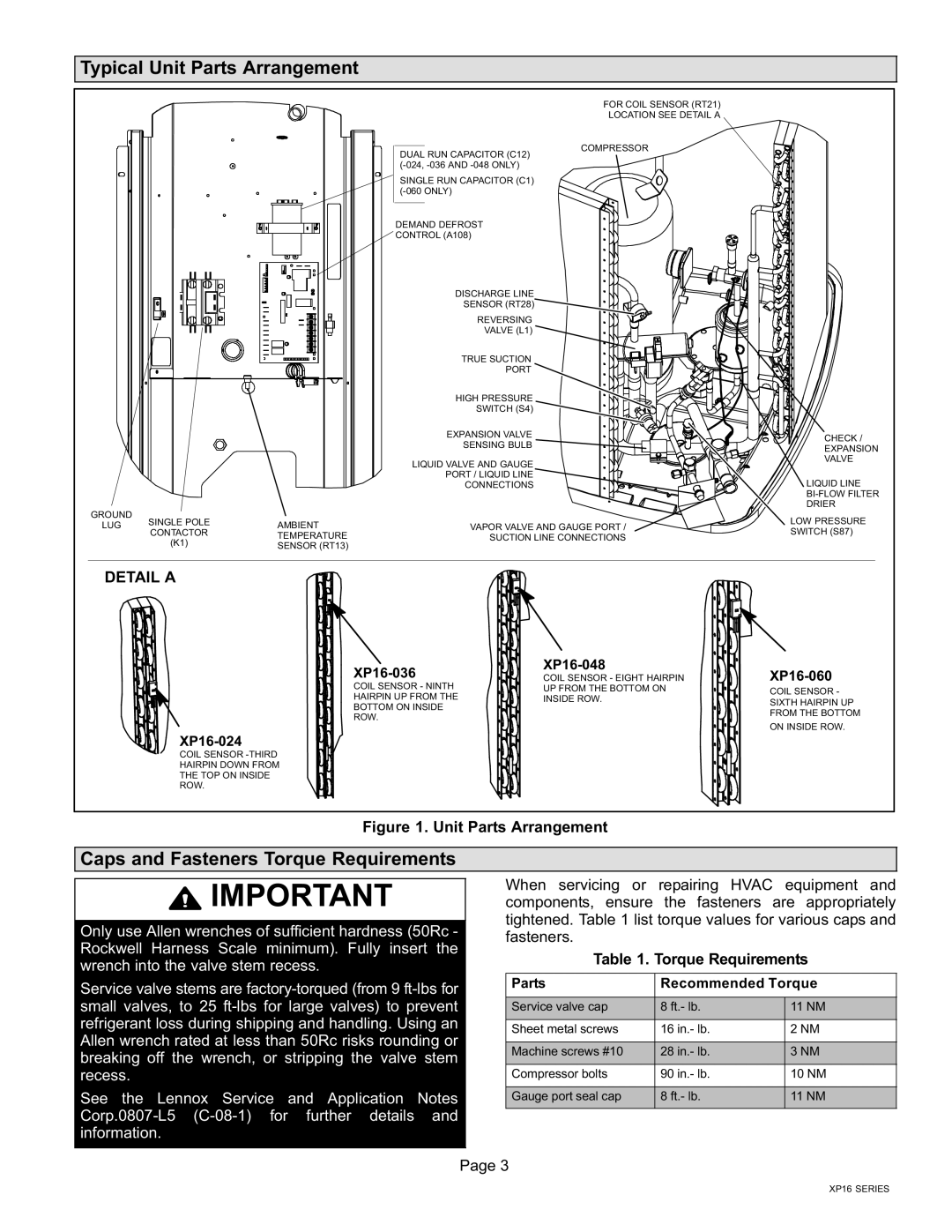

Typical Unit Parts Arrangement

FOR COIL SENSOR (RT21)

LOCATION SEE DETAIL A

|

|

| COMPRESSOR | |

|

|

| DUAL RUN CAPACITOR (C12) | |

|

|

| (−024, −036 AND −048 ONLY) | |

|

|

| SINGLE RUN CAPACITOR (C1) | |

|

|

| (−060 ONLY) | |

|

|

| DEMAND DEFROST | |

|

|

| CONTROL (A108) | |

|

|

| DISCHARGE LINE | |

|

|

| SENSOR (RT28) | |

|

|

| REVERSING | |

|

|

| VALVE (L1) | |

|

|

| TRUE SUCTION | |

|

|

| PORT | |

|

|

| HIGH PRESSURE | |

|

|

| SWITCH (S4) | |

|

|

| EXPANSION VALVE | |

|

|

| SENSING BULB | |

|

|

| LIQUID VALVE AND GAUGE | |

|

|

| PORT / LIQUID LINE | |

|

|

| CONNECTIONS | |

GROUND | SINGLE POLE |

|

| |

LUG | AMBIENT | VAPOR VALVE AND GAUGE PORT / | ||

CONTACTOR | ||||

| TEMPERATURE | SUCTION LINE CONNECTIONS | ||

| (K1) | |||

| SENSOR (RT13) |

| ||

|

|

|

CHECK /

EXPANSION

VALVE

LIQUID LINE BI−FLOW FILTER DRIER

LOW PRESSURE SWITCH (S87)

DETAIL A

XP16−036

COIL SENSOR − NINTH

HAIRPIN UP FROM THE

BOTTOM ON INSIDE

ROW.

XP16−024

COIL SENSOR −THIRD

HAIRPIN DOWN FROM

THE TOP ON INSIDE

ROW.

XP16−048

COIL SENSOR − EIGHT HAIRPIN UP FROM THE BOTTOM ON INSIDE ROW.

XP16−060

COIL SENSOR − SIXTH HAIRPIN UP FROM THE BOTTOM

ON INSIDE ROW.

Figure 1. Unit Parts Arrangement

Caps and Fasteners Torque Requirements

IMPORTANT

When servicing or repairing HVAC equipment and components, ensure the fasteners are appropriately tightened. Table 1 list torque values for various caps and fasteners.

Table 1. Torque Requirements

Parts | Recommended Torque | |

Service valve cap | 8 ft.− lb. | 11 NM |

Sheet metal screws | 16 in.− lb. | 2 NM |

Machine screws #10 | 28 in.− lb. | 3 NM |

Compressor bolts | 90 in.− lb. | 10 NM |

Gauge port seal cap | 8 ft.− lb. | 11 NM |

Page 3

XP16 SERIES