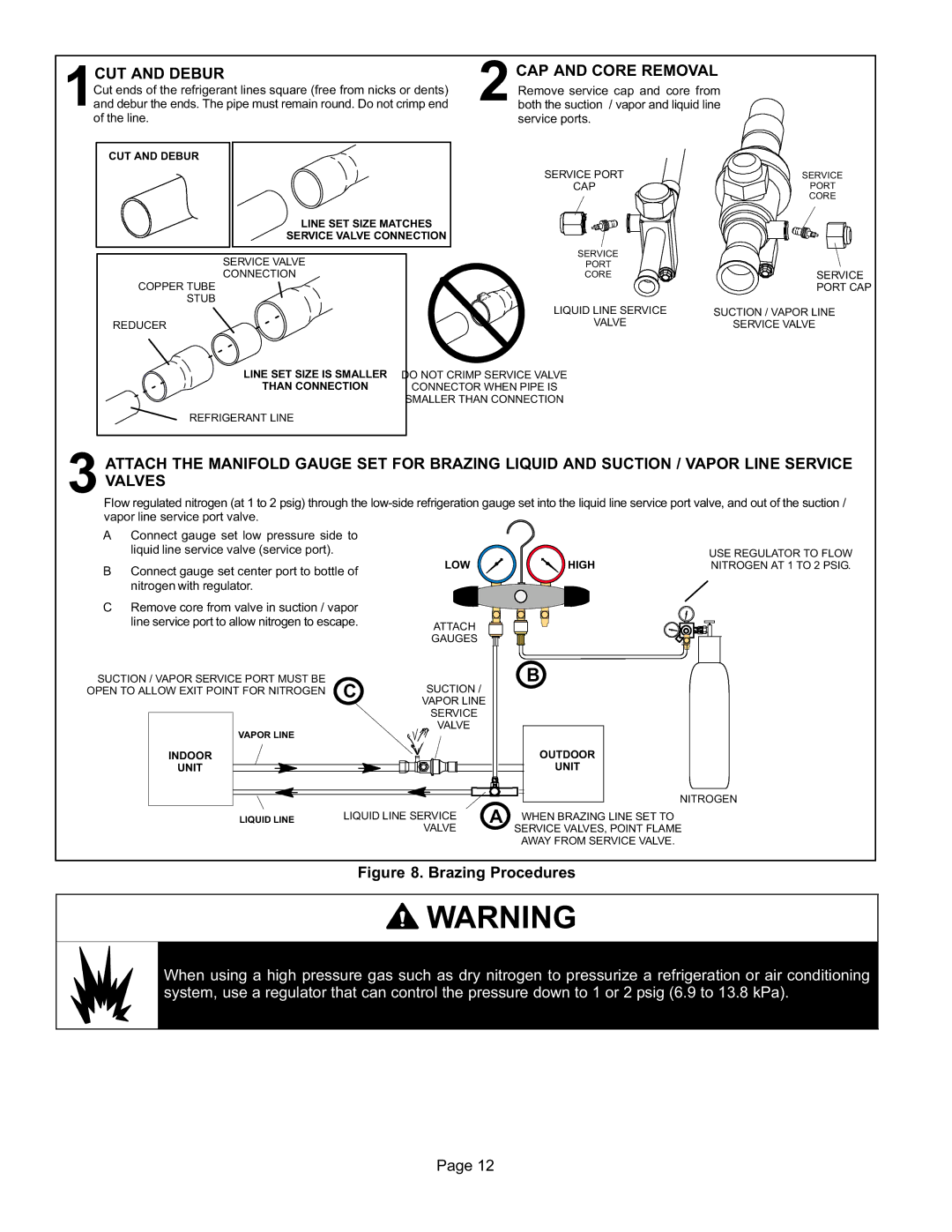

1CUT AND DEBUR

Cut ends of the refrigerant lines square (free from nicks or dents) and debur the ends. The pipe must remain round. Do not crimp end of the line.

2CAP AND CORE REMOVAL Remove service cap and core from both the suction / vapor and liquid line service ports.

CUT AND DEBUR

LINE SET SIZE MATCHES

SERVICE VALVE CONNECTION

SERVICE PORT | SERVICE |

CAP | PORT |

| CORE |

SERVICE VALVE | SERVICE |

|

PORT |

| |

CONNECTION | CORE | SERVICE |

COPPER TUBE |

| PORT CAP |

STUB |

|

|

| LIQUID LINE SERVICE | SUCTION / VAPOR LINE |

REDUCER | VALVE | SERVICE VALVE |

LINE SET SIZE IS SMALLER DO NOT CRIMP SERVICE VALVE |

| |

THAN CONNECTION | CONNECTOR WHEN PIPE IS |

|

| SMALLER THAN CONNECTION |

|

REFRIGERANT LINE |

|

|

3ATTACH THE MANIFOLD GAUGE SET FOR BRAZING LIQUID AND SUCTION / VAPOR LINE SERVICE VALVES

Flow regulated nitrogen (at 1 to 2 psig) through the low−side refrigeration gauge set into the liquid line service port valve, and out of the suction / vapor line service port valve.

AConnect gauge set low pressure side to liquid line service valve (service port).

BConnect gauge set center port to bottle of nitrogen with regulator.

CRemove core from valve in suction / vapor line service port to allow nitrogen to escape.

SUCTION / VAPOR SERVICE PORT MUST BE | C |

OPEN TO ALLOW EXIT POINT FOR NITROGEN |

VAPOR LINE

INDOOR

UNIT

LOW

ATTACH

GAUGES

SUCTION /

VAPOR LINE

SERVICE

VALVE

HIGH

B

OUTDOOR

UNIT

USE REGULATOR TO FLOW NITROGEN AT 1 TO 2 PSIG.

NITROGEN

LIQUID LINE | LIQUID LINE SERVICE | A WHEN BRAZING LINE SET TO |

| VALVE | SERVICE VALVES, POINT FLAME |

|

| AWAY FROM SERVICE VALVE. |

Figure 8. Brazing Procedures

![]() WARNING

WARNING

When using a high pressure gas such as dry nitrogen to pressurize a refrigeration or air conditioning system, use a regulator that can control the pressure down to 1 or 2 psig (6.9 to 13.8 kPa).

Page 12