Maintenance

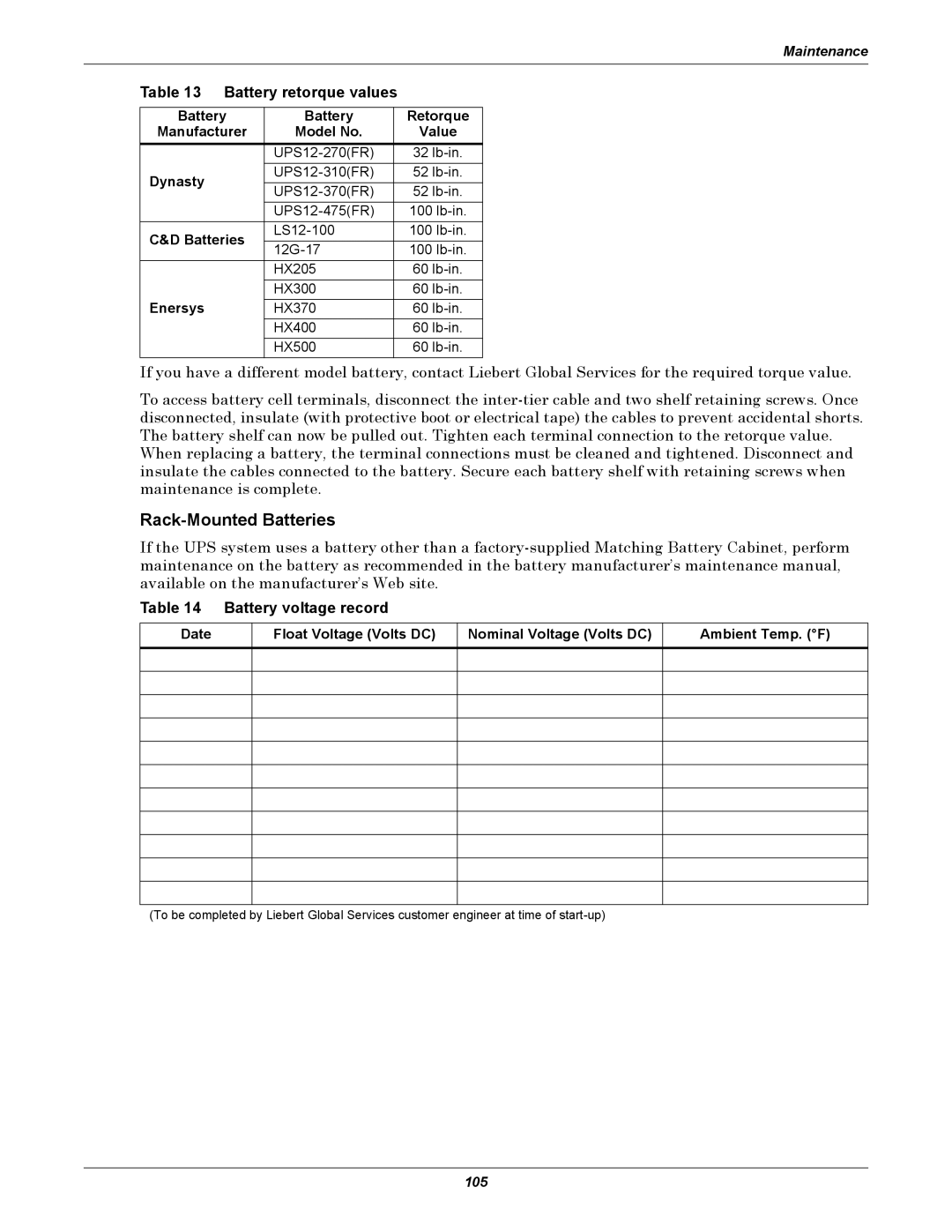

Table 13 Battery retorque values

Battery | Battery | Retorque | |

Manufacturer | Model No. | Value | |

| 32 | ||

Dynasty | 52 | ||

52 | |||

| |||

| 100 | ||

C&D Batteries | 100 | ||

100 | |||

| |||

| HX205 | 60 | |

| HX300 | 60 | |

Enersys | HX370 | 60 | |

| HX400 | 60 | |

| HX500 | 60 |

If you have a different model battery, contact Liebert Global Services for the required torque value.

To access battery cell terminals, disconnect the

When replacing a battery, the terminal connections must be cleaned and tightened. Disconnect and insulate the cables connected to the battery. Secure each battery shelf with retaining screws when maintenance is complete.

Rack-Mounted Batteries

If the UPS system uses a battery other than a

Table 14 Battery voltage record

Date

Float Voltage (Volts DC)

Nominal Voltage (Volts DC)

Ambient Temp. (°F)

(To be completed by Liebert Global Services customer engineer at time of

105