INSTALLATION | ||

|

|

|

STACKING

POWER ARC 5000 machines CANNOT be stacked.

TILTING

Place the machine on a secure, level surface whenev- er you use it or store it. Any surfaces you place it on other than the ground must be firm,

The gasoline engine is designed to run in a level posi- tion for best performance. It can operate at an angle, but this should never be more than 15 degrees in any direction. If you do operate it at a slight angle, be sure to check the oil regularly and keep the oil level full. Also, fuel capacity will be a little less at an angle.

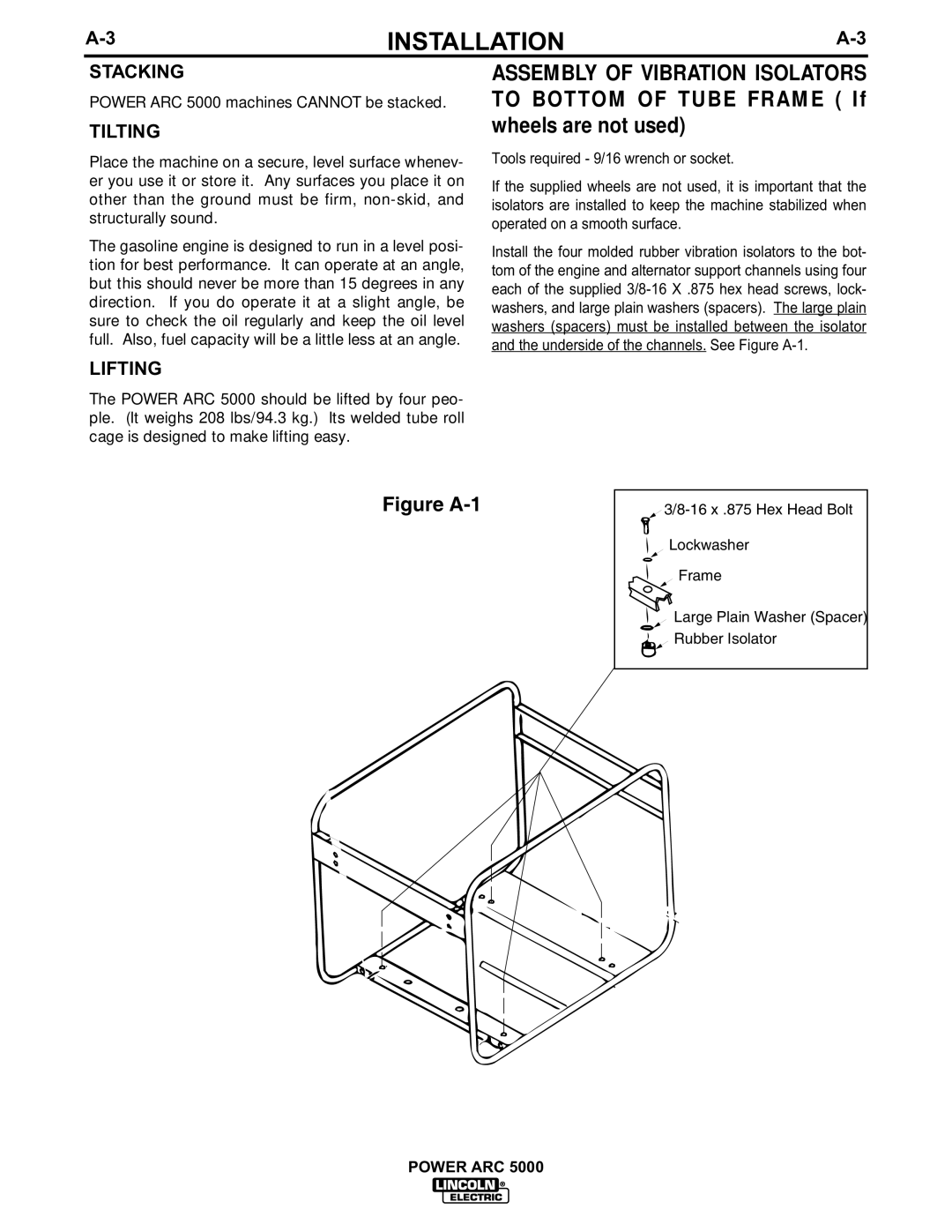

ASSEMBLY OF VIBRATION ISOLATORS TO BOTTOM OF TUBE FRAME ( If wheels are not used)

Tools required - 9/16 wrench or socket.

If the supplied wheels are not used, it is important that the isolators are installed to keep the machine stabilized when operated on a smooth surface.

Install the four molded rubber vibration isolators to the bot- tom of the engine and alternator support channels using four each of the supplied

LIFTING

The POWER ARC 5000 should be lifted by four peo- ple. (It weighs 208 lbs/94.3 kg.) Its welded tube roll cage is designed to make lifting easy.

Figure A-1

![]()

Lockwasher

Frame

Large Plain Washer (Spacer) ![]()

![]() Rubber Isolator

Rubber Isolator

POWER ARC 5000