OPERATION | ||

|

|

|

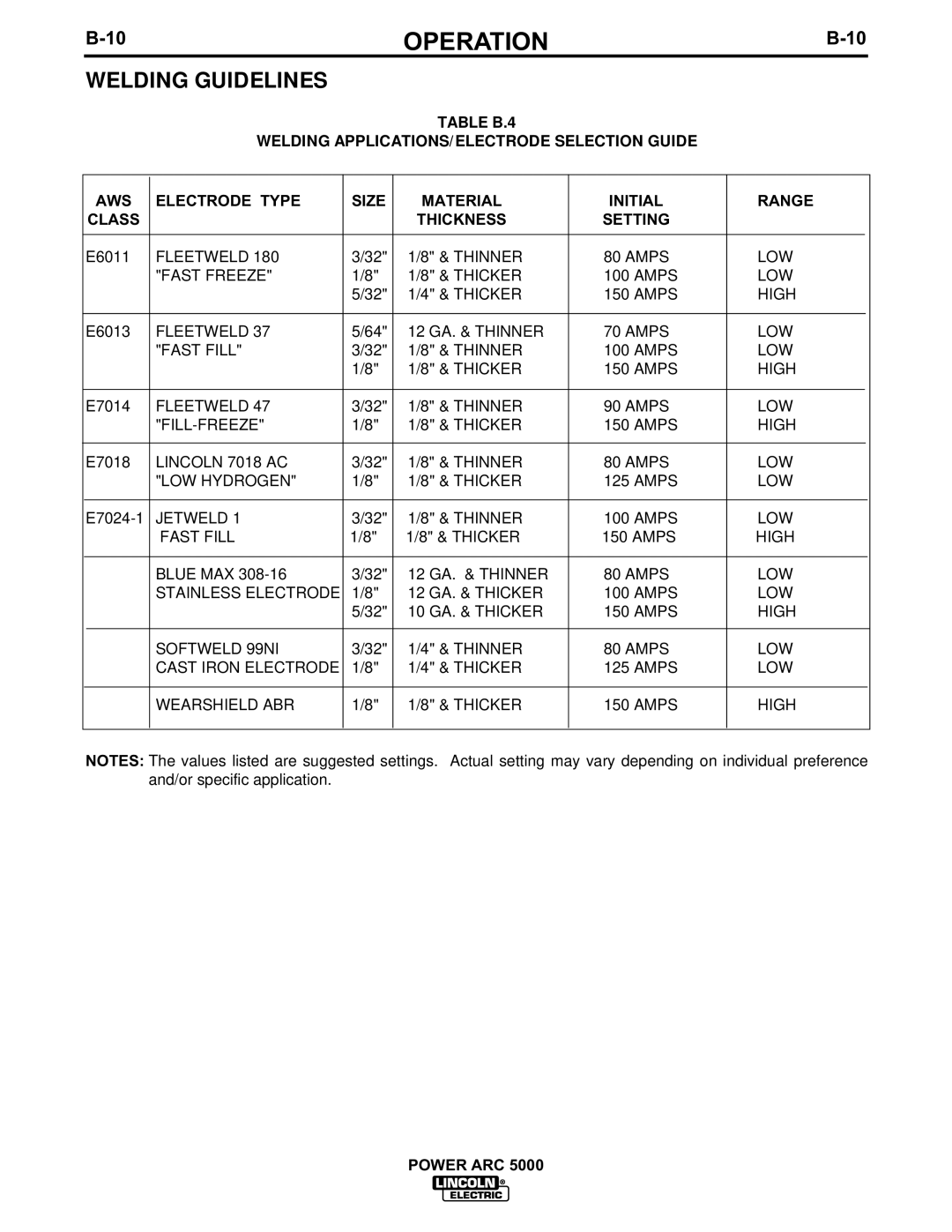

WELDING GUIDELINES

TABLE B.4

WELDING APPLICATIONS/ELECTRODE SELECTION GUIDE

| AWS |

| ELECTRODE TYPE | SIZE | MATERIAL | INITIAL | RANGE | ||

|

| ||||||||

| CLASS |

|

|

| THICKNESS | SETTING |

|

|

|

|

|

|

|

|

|

|

|

|

|

E6011 |

| FLEETWELD 180 | 3/32" | 1/8" & THINNER | 80 AMPS | LOW | |||

|

|

| "FAST FREEZE" | 1/8" | 1/8" & THICKER | 100 AMPS | LOW | ||

|

|

|

| 5/32" | 1/4" & THICKER | 150 AMPS | HIGH | ||

|

|

|

|

|

|

|

|

| |

E6013 |

| FLEETWELD 37 | 5/64" | 12 GA. & THINNER | 70 AMPS | LOW | |||

|

|

| "FAST FILL" | 3/32" | 1/8" & THINNER | 100 AMPS | LOW | ||

|

|

|

| 1/8" | 1/8" & THICKER | 150 AMPS | HIGH | ||

|

|

|

|

|

|

|

|

|

|

E7014 |

| FLEETWELD 47 | 3/32" | 1/8" & THINNER | 90 AMPS | LOW | |||

|

|

| 1/8" | 1/8" & THICKER | 150 AMPS | HIGH | |||

|

|

|

|

|

|

|

|

| |

E7018 |

| LINCOLN 7018 AC | 3/32" | 1/8" & THINNER | 80 AMPS | LOW | |||

|

|

| "LOW HYDROGEN" | 1/8" | 1/8" & THICKER | 125 AMPS | LOW | ||

|

|

|

|

|

|

|

|

| |

| JETWELD 1 | 3/32" | 1/8" & THINNER | 100 AMPS | LOW | ||||

|

|

| “FAST FILL” | 1/8" | 1/8" & THICKER | 150 AMPS | HIGH | ||

|

|

|

|

|

|

|

|

| |

|

|

| BLUE MAX | 3/32" | 12 GA. & THINNER | 80 AMPS | LOW | ||

|

|

| STAINLESS ELECTRODE | 1/8" | 12 GA. & THICKER | 100 AMPS | LOW | ||

|

|

|

| 5/32" | 10 GA. & THICKER | 150 AMPS | HIGH | ||

|

|

|

|

|

|

|

| ||

|

|

| SOFTWELD 99NI | 3/32" | 1/4" & THINNER | 80 AMPS | LOW | ||

|

|

| CAST IRON ELECTRODE | 1/8" | 1/4" & THICKER | 125 AMPS | LOW | ||

|

|

|

|

|

|

|

|

| |

|

|

| WEARSHIELD ABR | 1/8" | 1/8" & THICKER | 150 AMPS | HIGH | ||

|

|

|

|

|

|

|

|

|

|

NOTES: The values listed are suggested settings. Actual setting may vary depending on individual preference and/or specific application.

POWER ARC 5000