| TROUBLESHOOTING | |||

|

|

|

|

|

| Observe all Safety Guidelines detailed throughout this manual | |||

|

|

|

|

|

| PROBLEMS | POSSIBLE AREAS OF | RECOMMENDED | |

| (SYMPTOMS) | MISADJUSTMENTS(S) | COURSE OF ACTION |

|

|

|

|

|

|

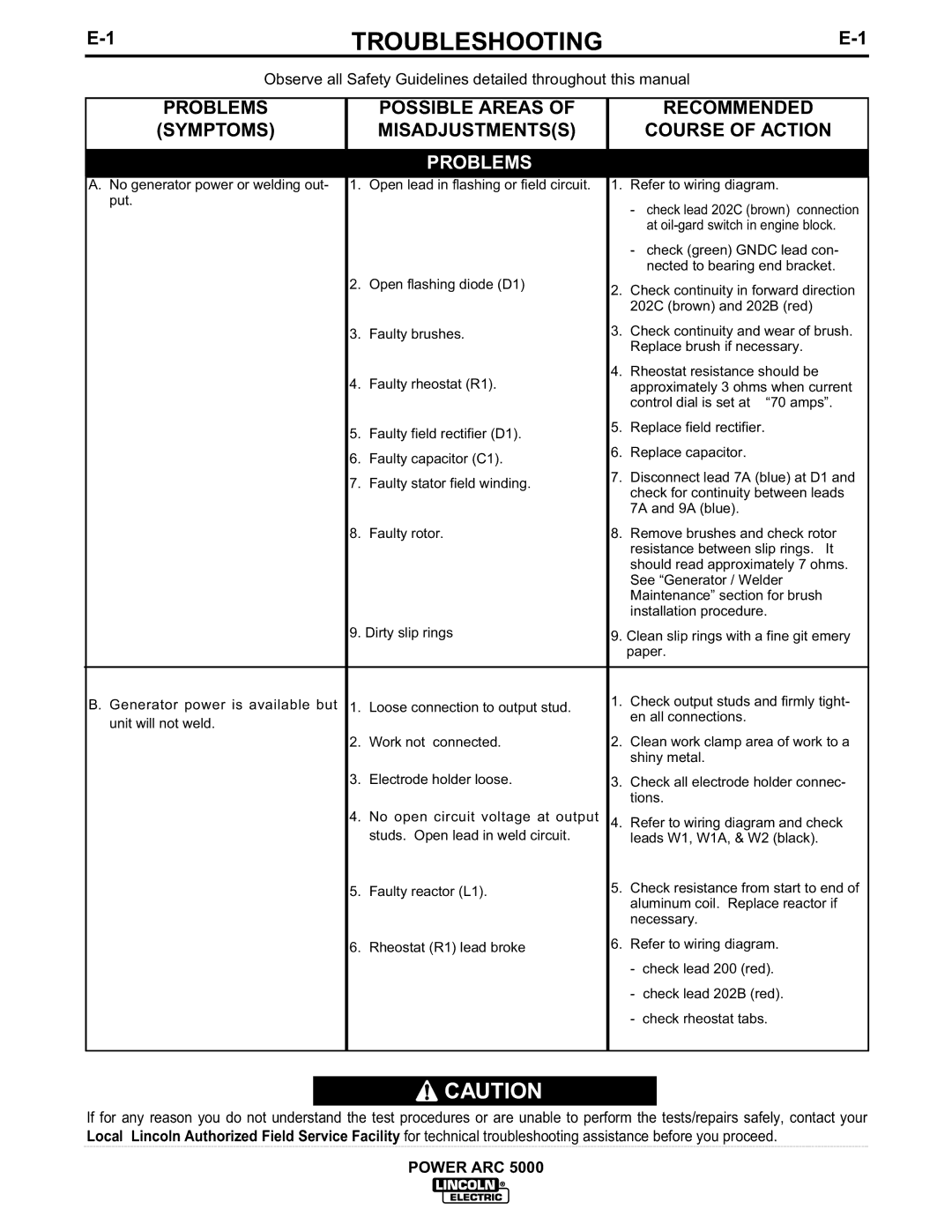

PROBLEMS

A.No generator power or welding out- 1. Open lead in flashing or field circuit. 1. Refer to wiring diagram. put.

-check lead 202C (brown) connection at

-check (green) GNDC lead con- nected to bearing end bracket.

2. | Open flashing diode (D1) | 2. | Check continuity in forward direction | |

|

|

| 202C (brown) and 202B (red) | |

3. | Faulty brushes. | 3. | Check continuity and wear of brush. | |

|

|

| Replace brush if necessary. | |

4. | Faulty rheostat (R1). | 4. | Rheostat resistance should be | |

| approximately 3 ohms when current | |||

|

|

| control dial is set at “70 amps”. | |

5. | Faulty field rectifier (D1). | 5. | Replace field rectifier. | |

|

|

| ||

6. | Faulty capacitor (C1). | 6. | Replace capacitor. | |

|

|

| ||

7. | Faulty stator field winding. | 7. | Disconnect lead 7A (blue) at D1 and | |

| check for continuity between leads | |||

|

|

| ||

|

|

| 7A and 9A (blue). | |

8. | Faulty rotor. | 8. | Remove brushes and check rotor | |

|

|

| resistance between slip rings. It | |

|

|

| should read approximately 7 ohms. | |

|

|

| See “Generator / Welder | |

|

|

| Maintenance” section for brush | |

|

|

| installation procedure. | |

9. Dirty slip rings | 9. Clean slip rings with a fine git emery | |||

|

|

| paper. | |

|

|

|

| |

B. Generator power is available but 1. | Loose connection to output stud. | 1. | Check output studs and firmly tight- | |

unit will not weld. |

|

| en all connections. | |

| 2. | Clean work clamp area of work to a | ||

2. | Work not connected. | |||

|

|

| shiny metal. | |

3. | Electrode holder loose. | 3. | Check all electrode holder connec- | |

|

|

| tions. | |

4. | No open circuit voltage at output | 4. | Refer to wiring diagram and check | |

| studs. Open lead in weld circuit. |

| leads W1, W1A, & W2 (black). | |

5. | Faulty reactor (L1). | 5. | Check resistance from start to end of | |

|

|

| aluminum coil. Replace reactor if | |

|

|

| necessary. | |

6. | Rheostat (R1) lead broke | 6. | Refer to wiring diagram. | |

|

|

| - | check lead 200 (red). |

|

|

| - | check lead 202B (red). |

|

|

| - | check rheostat tabs. |

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

POWER ARC 5000