MAINTENANCE | ||

|

|

|

GENERATOR/WELDER MAINTENANCE

STORAGE: Store the POWER ARC 5000 in clean, dry, protected areas.

CLEANING: Blow out the generator and controls periodically with low pressure air. Do this at least once a week in particularly dirty areas.

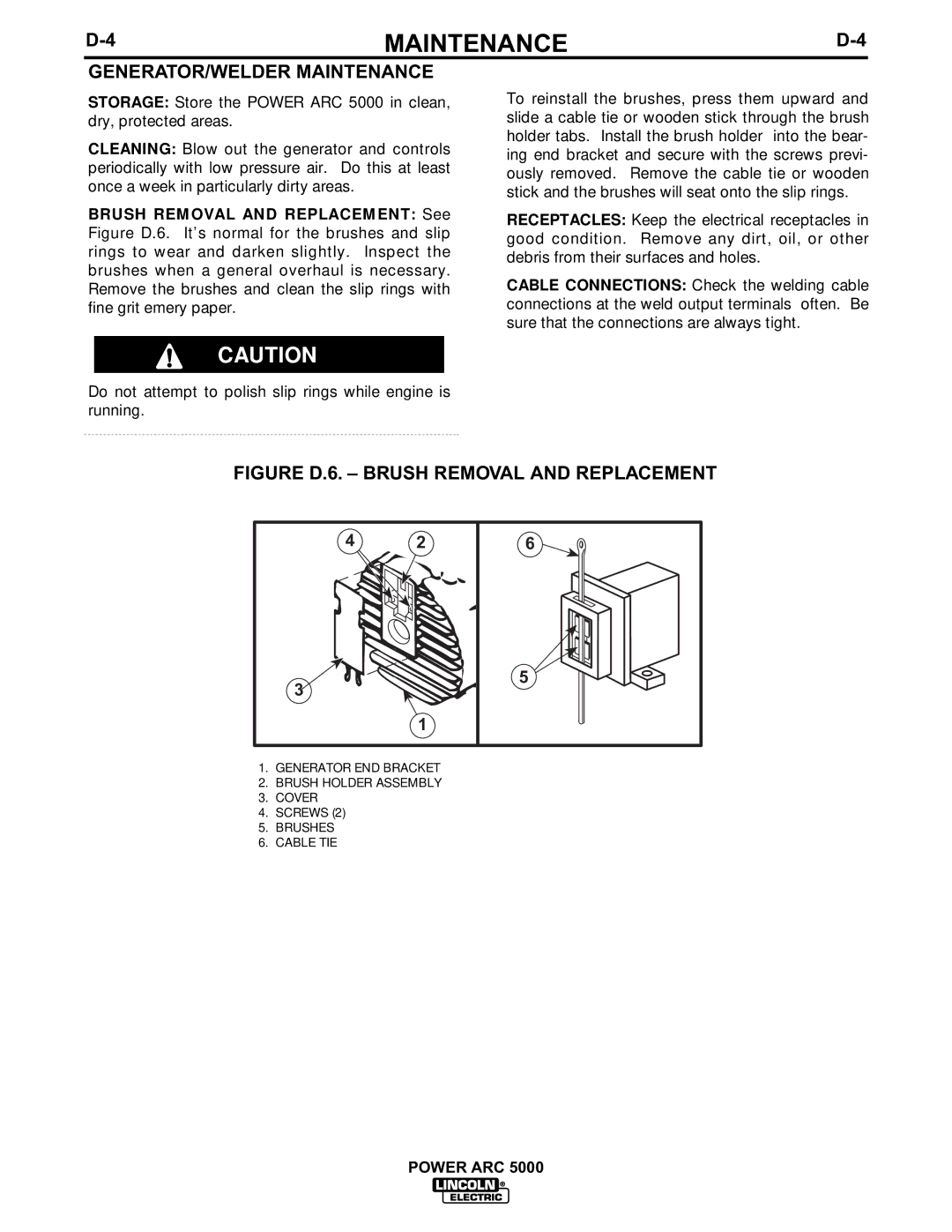

BRUSH REMOVAL AND REPLACEMENT: See Figure D.6. It’s normal for the brushes and slip rings to wear and darken slightly. Inspect the brushes when a general overhaul is necessary. Remove the brushes and clean the slip rings with fine grit emery paper.

To reinstall the brushes, press them upward and slide a cable tie or wooden stick through the brush holder tabs. Install the brush holder into the bear- ing end bracket and secure with the screws previ- ously removed. Remove the cable tie or wooden stick and the brushes will seat onto the slip rings.

RECEPTACLES: Keep the electrical receptacles in good condition. Remove any dirt, oil, or other debris from their surfaces and holes.

CABLE CONNECTIONS: Check the welding cable connections at the weld output terminals often. Be sure that the connections are always tight.

CAUTION

Do not attempt to polish slip rings while engine is running.

FIGURE D.6. – BRUSH REMOVAL AND REPLACEMENT

4 | 2 | 6 |

3 |

| 5 |

|

| |

| 1 |

|

1.GENERATOR END BRACKET

2.BRUSH HOLDER ASSEMBLY

3.COVER

4.SCREWS (2)

5.BRUSHES

6.CABLE TIE

POWER ARC 5000