MAINTENANCE | ||

|

|

|

CLEAN AIR FILTER PRE-CLEANER

CAUTION

Do not use petroleum solvents such as kerosene to clean the air

IZED AIR TO CLEAN OR DRY THE AIR PRE-CLEANER.

To service the

1.Wash in liquid detergent and water.

2.Squeeze dry in a clean cloth.

3.Saturate in clean engine oil.

4.Squeeze in a clean, absorbent cloth to remove all excess oil.

CLEAN ENGINE: Remove dirt and debris with a cloth or a brush. Do not clean with a forceful spray of water. Water might contaminate the fuel system.

CAUTION

Periodically clean the muffler area to remove com- bustible debris.

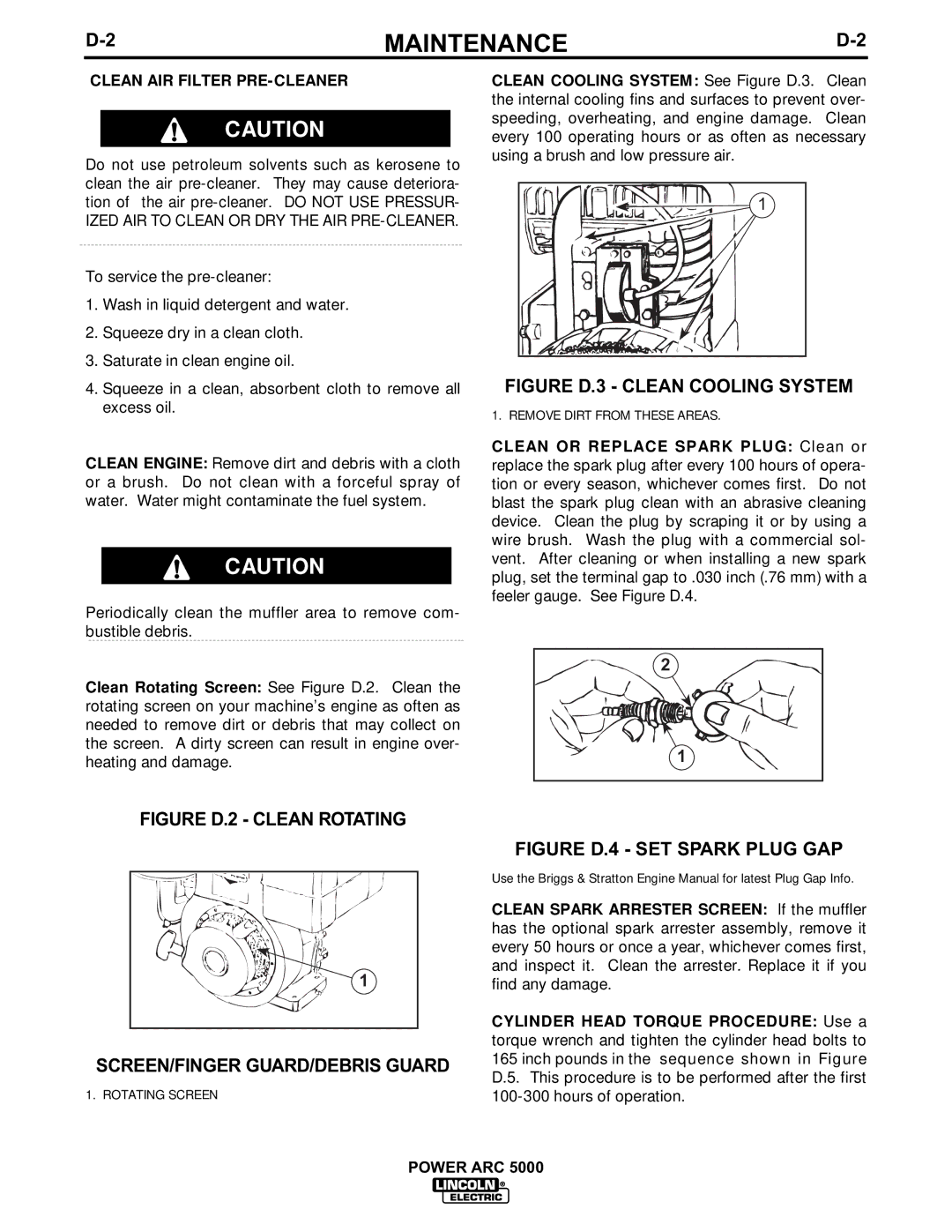

CLEAN COOLING SYSTEM: See Figure D.3. Clean the internal cooling fins and surfaces to prevent over- speeding, overheating, and engine damage. Clean every 100 operating hours or as often as necessary using a brush and low pressure air.

1 |

FIGURE D.3 - CLEAN COOLING SYSTEM

1. REMOVE DIRT FROM THESE AREAS.

CLEAN OR REPLACE SPARK PLUG: Clean or replace the spark plug after every 100 hours of opera- tion or every season, whichever comes first. Do not blast the spark plug clean with an abrasive cleaning device. Clean the plug by scraping it or by using a wire brush. Wash the plug with a commercial sol- vent. After cleaning or when installing a new spark plug, set the terminal gap to .030 inch (.76 mm) with a feeler gauge. See Figure D.4.

Clean Rotating Screen: See Figure D.2. Clean the rotating screen on your machine’s engine as often as needed to remove dirt or debris that may collect on the screen. A dirty screen can result in engine over- heating and damage.

2

1

FIGURE D.2 - CLEAN ROTATING

1

SCREEN/FINGER GUARD/DEBRIS GUARD

1. ROTATING SCREEN

FIGURE D.4 - SET SPARK PLUG GAP

Use the Briggs & Stratton Engine Manual for latest Plug Gap Info.

CLEAN SPARK ARRESTER SCREEN: If the muffler has the optional spark arrester assembly, remove it every 50 hours or once a year, whichever comes first, and inspect it. Clean the arrester. Replace it if you find any damage.

CYLINDER HEAD TORQUE PROCEDURE: Use a torque wrench and tighten the cylinder head bolts to 165 inch pounds in the sequence shown in Figure D.5. This procedure is to be performed after the first

POWER ARC 5000