Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Section TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

Return to Master TOC

TROUBLESHOOTING & REPAIR |

| |||||||

|

|

|

|

|

|

| ||

|

|

|

|

| ||||

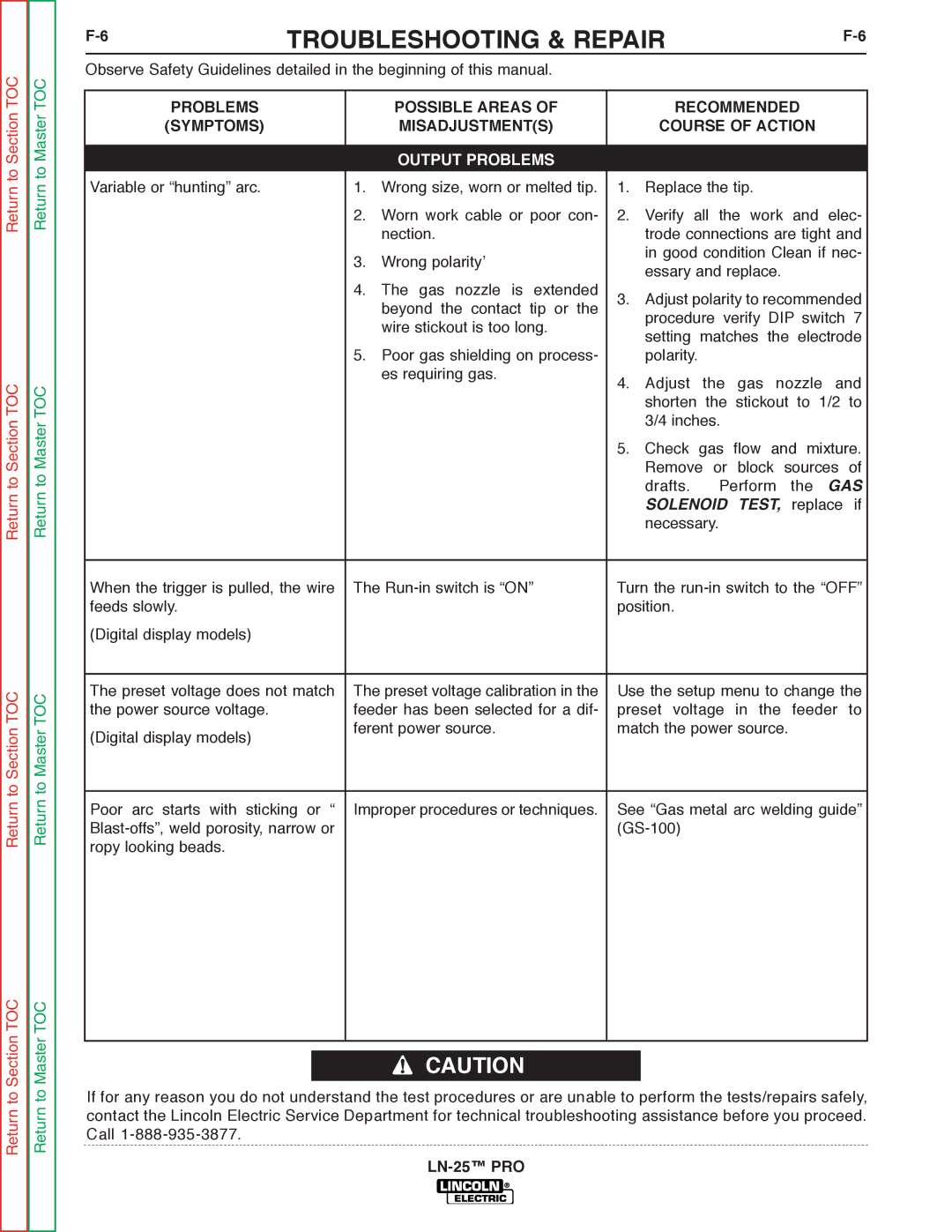

Observe Safety Guidelines detailed in the beginning of this manual. |

|

|

|

| ||||

|

|

|

|

|

| |||

PROBLEMS |

|

| POSSIBLE AREAS OF |

| RECOMMENDED | |||

(SYMPTOMS) |

|

| MISADJUSTMENT(S) |

| COURSE OF ACTION | |||

|

|

|

|

|

|

|

| |

|

|

| OUTPUT PROBLEMS |

|

|

|

| |

Variable or “hunting” arc. |

| 1. Wrong size, worn or melted tip. | 1. | Replace the tip. |

| |||

|

| 2. Worn work cable or poor con- | 2. | Verify | all the work | and elec- | ||

|

|

| nection. |

|

| trode connections are tight and | ||

|

| 3. | Wrong polarity’ |

|

| in good condition Clean if nec- | ||

|

|

|

| essary and replace. |

| |||

|

|

|

|

|

|

| ||

|

| 4. | The gas nozzle is | extended | 3. | Adjust polarity to recommended | ||

|

|

| beyond the contact | tip or the | ||||

|

|

|

| procedure verify DIP switch 7 | ||||

|

|

| wire stickout is too long. |

| ||||

|

|

|

| setting | matches the | electrode | ||

|

|

|

|

|

| |||

|

| 5. Poor gas shielding on process- |

| polarity. |

| |||

|

|

| es requiring gas. |

| 4. Adjust | the gas nozzle and | ||

|

|

|

|

| ||||

|

|

|

|

|

| shorten the stickout to 1/2 to | ||

|

|

|

|

|

| 3/4 inches. |

| |

|

|

|

|

| 5. Check | gas flow and mixture. | ||

|

|

|

|

|

| Remove or block sources of | ||

|

|

|

|

|

| drafts. | Perform | the GAS |

|

|

|

|

|

| SOLENOID TEST, | replace if | |

|

|

|

|

|

| necessary. |

| |

|

|

| ||||||

When the trigger is pulled, the wire | The | Turn the | ||||||

feeds slowly. |

|

|

|

| position. |

|

| |

(Digital display models) |

|

|

|

|

|

|

|

|

|

|

| ||||||

The preset voltage does not match | The preset voltage calibration in the | Use the setup menu to change the | ||||||

the power source voltage. |

| feeder has been selected for a dif- | preset voltage in the feeder to | |||||

(Digital display models) |

| ferent power source. |

| match the power source. |

| |||

|

|

|

|

|

|

|

| |

|

|

| ||||||

Poor arc starts with sticking or “ | Improper procedures or techniques. | See “Gas metal arc welding guide” | ||||||

|

|

|

|

| ||||

ropy looking beads. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact the Lincoln Electric Service Department for technical troubleshooting assistance before you proceed. Call