Models 90,000 500,000 Btu/hr

Contents

Please read before proceeding

Checking equipment

Codes

Ratings

Copper-fin =B=R Rating

Copper-fin Specifications

Copper-fin How it works

Gas connection pipe

Models CWN270 Front View Model CWN399 Front View

422

Determine unit location

Location of unit

Determine boiler location

3Combustion Air Direct from Outside

6Combustion Air from Outside Single Opening

Minimum Recommended Combustion AIR Supply to Equipment Room

Vent Pipe Sizes

Venting

Conventional Negative Draft Venting System

Venting

Vertical Vent Termination Clearances

Less from Ridge From Parapet Wall

Masonry Chimney Installation

Vent Materials

Sidewall Venting

Number

Automatic Vent Damper

7CB with Vent Damper and Vent Damper Terminal Block

Gas connections

Gas Supply Gas Pressure Test

Gas Connection

Manifold Pressure

Install Piping to Control

Gas Piping

Gas Manifold Pressure Adjustment Procedure

Clockwise to raise regulator gas pressure, counterclockwise

Checking Gas Supply Pressure

4Gas Supply Pressure

Two Stage Burner Control System

Combination Gas Valves

Venting of Combination Gas Valves

Relief Valve

Water Flow Switch if equipped

Hydronic piping

Typical Heating Boiler Installations

Low Water Cutoff if equipped

Minimum Required Flow For Heating Boiler

General Plumbing Rules

System Temperature Rise Chart

Piping of the Boiler System

Heat Exchanger Pressure Drop Chart

Circulator Pump Specifications

Water Connections Heating Boilers Only

Circulator Pump Requirements

Primary/Secondary Boiler Piping

Three Way Valves

Boiler Flow Rates

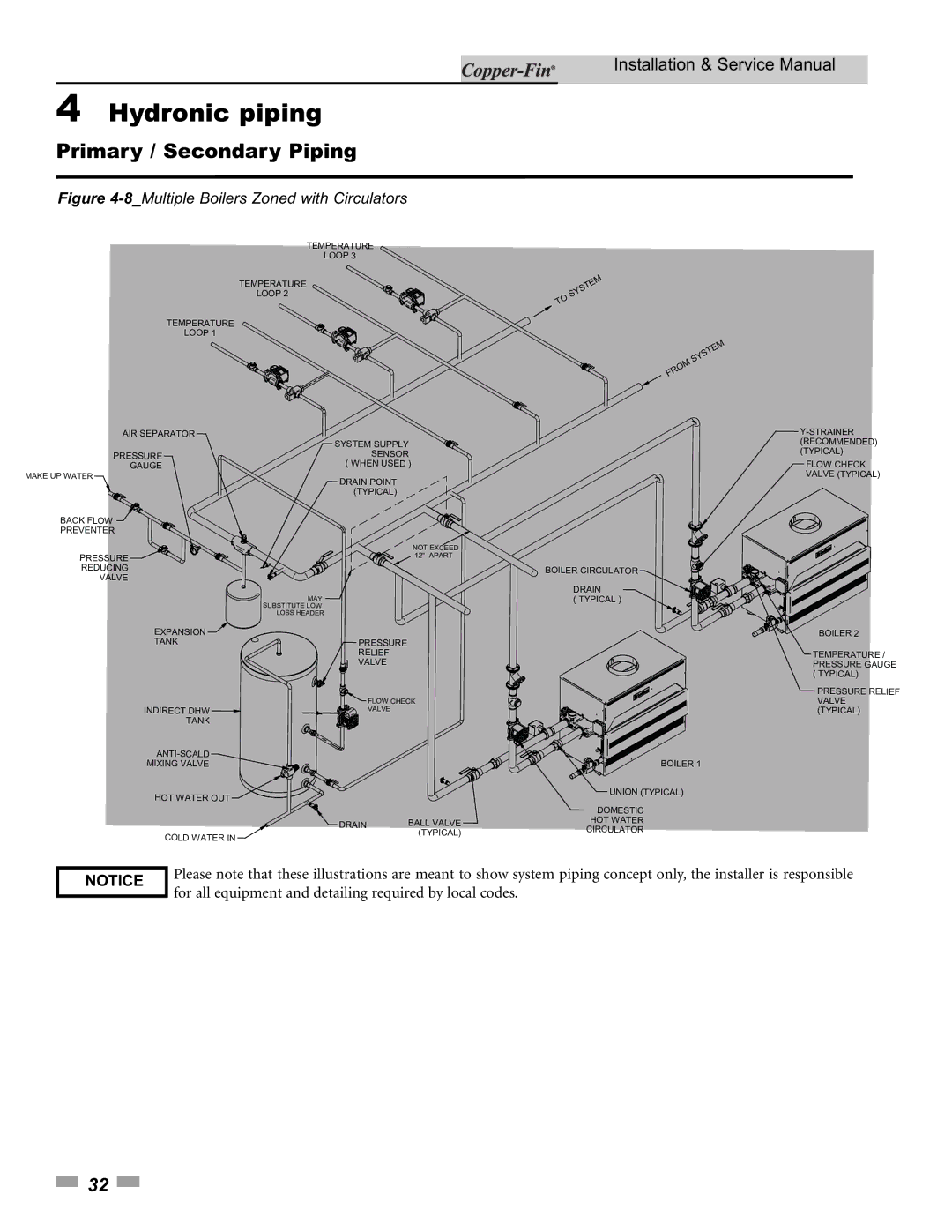

Primary / Secondary Piping

4Primary / Secondary Piping of a Single Boiler

Not to Exceed 4 Pipe DIA or MAX. of 12 Apart

8Multiple Boilers Zoned with Circulators

Terminal Strip Wiring

Boiler Operating Temperature Control

Power Venter Connection to Terminal Strip

Electrical connections

Operating Temperature Control

Temperature Adjustment

Pump Wiring for a Heating Boiler

Locating Temperature Control

Temperature Control Settings

Maximum SET Point Determination

Maximum Set Point Determination

Temperature Control Sensors

Inlet Water Temperature Sensor

Multi-Purpose Temperature Sensor

Outdoor Air Temperature Sensor

Installation of a Tank Sensor Water Heater Application

Outdoor Air Reset Option

Installation of a Remote Sensor Boiler Application

Additional Temperature Controls

Blocked Vent and Flame Roll-Out / Flame Interlock Switch

Manual Reset High Water Temperature Limit Control

Initial Start-up

Pre-start Checklist

Start-up

Lighting Instructions

1Gas Valve 90,000 270,000 Btu/hr Models

Safety Shutoff Test For Standing Pilot Ignition System

To Turn OFF GAS to Appliance

Operating Instructions

Safety Shutoff Test for Spark Ignition Pilot System

Intermittent Pilot Spark Ignition System F9/M9

Freeze Protection

To Turn Off Gas to Appliance

Water Treatment

Freeze Protection for a Heating Boiler System if required

Required Temperature Rise

Required Temperature Rise

Domestic water heaters

Domestic Water Heaters 90,000 500,000 Btu/hr Models

Pump Operation

Water Chemistry

Softened Water Systems

1Single water heatersingle tank

2Single water heatermultiple tank

3Multiple water heatersingle tank

Remote Sensor Installation

Thermostat Settings

Minimum Pump Performance

Heat Exchanger

5Danger Warning

Water Flow Switch if equipped

Pressure Only Relief Valve

Thermal Expansion

Cathodic Protection

Maintenance and annual startup

Service technician

Owner maintenance

See the User’s Information Manual for instructions

Maintenance

Check Expansion Tank

Check Relief Valve

Check All Wiring

Check Control Settings

Combustion Air Adjustment

Perform Start-up and Checks

Inspection and Cleaning Procedure

Inspect and Clean Burner

Heat Exchanger / Burner Access

Pilot Flame Adjustment Procedure

Clear Area

Inspection of Heat Exchanger Waterways

Water Circulating Pump

Review with owner

Gas Train and Controls

Troubleshooting

Pilot or replace

Diagrams

Schematic Diagram F1 Unit

Wiring Diagram F1 Unit

90,000 270,000 Btu/hr Models

315,000 399,999 Btu/hr Models

Schematic Diagram F9 Unit

Wiring Diagram F9 Unit

Diagrams

Diagrams

Page

Revision a ECO #C06290 initial release CFA-I-S Rev a 09/10

![]() PREVENTER

PREVENTER![]()

![]()

![]() REDUCING VALVE

REDUCING VALVE![]() 32

32 ![]()