3Gas connections (continued)

| WHEN FLANGE |

| IS USED |

| WHEN FLANGE |

APPLY WRENCH | IS NOT USED |

TO FLANGE ONLY |

|

APPLY WRENCH FROM

BOTTOM OF GAS CONTROL

TO EITHER SHADED AREA

Figure 3-2_Wrench

8.For L.P. gas, consult your L.P. gas supplier for expert installation.

Installation & Service Manual

1. | Turn the power “OFF” at the main disconnect switch. |

2. | Turn gas valve control knob to “PILOT” position on |

| standing pilot models. Ensure that the standing pilot |

| remains on. If the pilot goes out, follow the “Lighting |

| Instructions” in Section 6 - Startup for standing pilot |

| models to light the pilot. Turn gas valve control knob to |

| “OFF” position on spark ignition models. |

3. | Remove the 1/8" hex plug located on the outlet side of the |

| gas valve and install a fitting suitable to connect to a |

| manometer or magnahelic gauge. See FIG. |

| range of scale should be up to 5" w.c. for Natural gas |

| models and 10" w.c. for L.P. gas models. |

4. | The 500,000 Btu/hr model will have two gas valves with a |

| pressure regulator on each valve. Repeat the following |

| adjustment procedure to set the manifold pressure on each |

| gas valve. |

5. | Remove the pressure regulator adjustment cap screw on |

IMPORTANT

Upon completion of any piping connections to the gas system, leak test all gas connections with a soap solution while system is under pressure. Immediately repair any leaks found in the gas train or related components. Do Not operate an appliance with a leak in the gas train, valves or related piping.

| the gas valve. See FIG. |

6. | Turn the power “ON” at the main disconnect switch. |

7. | Turn gas valve control knob to “ON” position. |

8. | Set the thermostat(s) to call for heat. |

9. | Observe gas regulator pressure when all burners are firing. |

| See Table 3B, Manifold Pressure (page 19) for proper |

| regulator pressure settings. |

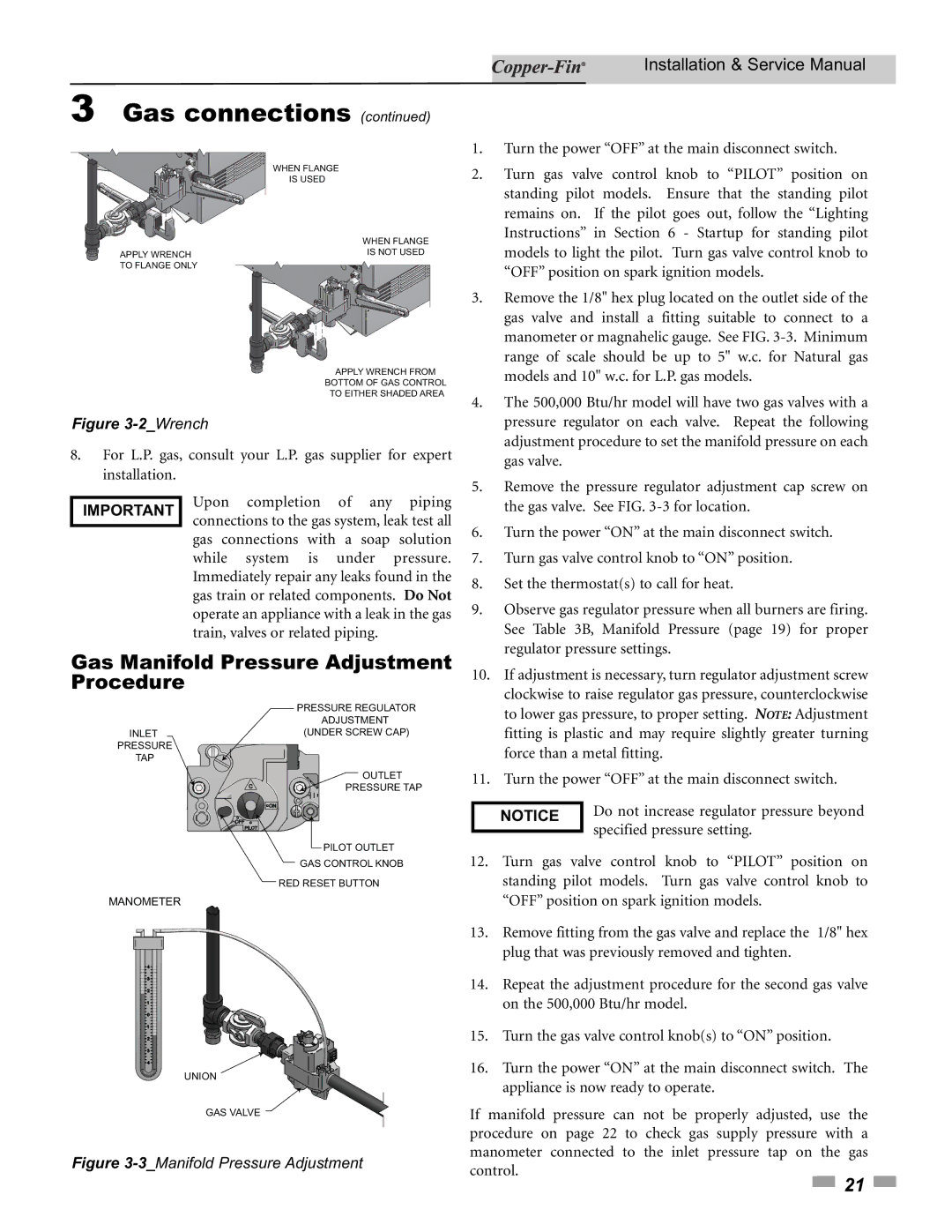

Gas Manifold Pressure Adjustment Procedure

10. If adjustment is necessary, turn regulator adjustment screw |

clockwise to raise regulator gas pressure, counterclockwise |

INLET

PRESSURE

TAP

MANOMETER

PRESSURE REGULATOR

ADJUSTMENT

(UNDER SCREW CAP)

OUTLET

PRESSURE TAP

PILOT OUTLET

GAS CONTROL KNOB

RED RESET BUTTON

to lower gas pressure, to proper setting. NOTE: Adjustment |

fitting is plastic and may require slightly greater turning |

force than a metal fitting. |

11. Turn the power “OFF” at the main disconnect switch. |

NOTICE | Do not increase regulator pressure beyond | |

specified pressure setting. | ||

| ||

|

12. | Turn gas valve control knob to “PILOT” position on |

| standing pilot models. Turn gas valve control knob to |

| “OFF” position on spark ignition models. |

13. | Remove fitting from the gas valve and replace the 1/8" hex |

| plug that was previously removed and tighten. |

14. | Repeat the adjustment procedure for the second gas valve |

| on the 500,000 Btu/hr model. |

15. | Turn the gas valve control knob(s) to “ON” position. |

16. | Turn the power “ON” at the main disconnect switch. The |

UNION

GAS VALVE

Figure 3-3_Manifold Pressure Adjustment

appliance is now ready to operate. |

If manifold pressure can not be properly adjusted, use the procedure on page 22 to check gas supply pressure with a manometer connected to the inlet pressure tap on the gas control.

![]() 21

21 ![]()