4Hydronic piping (continued)

A water flow switch meets most code requirements for a

Low Water Cutoff (if equipped)

A hot water boiler installed above radiation level must be provided with a low water cutoff device either as part of the unit or installed at the time the boiler is installed. An electronic low water cutoff is available as a kit on all units. Low water cutoffs should be inspected every six months, including flushing of float types.

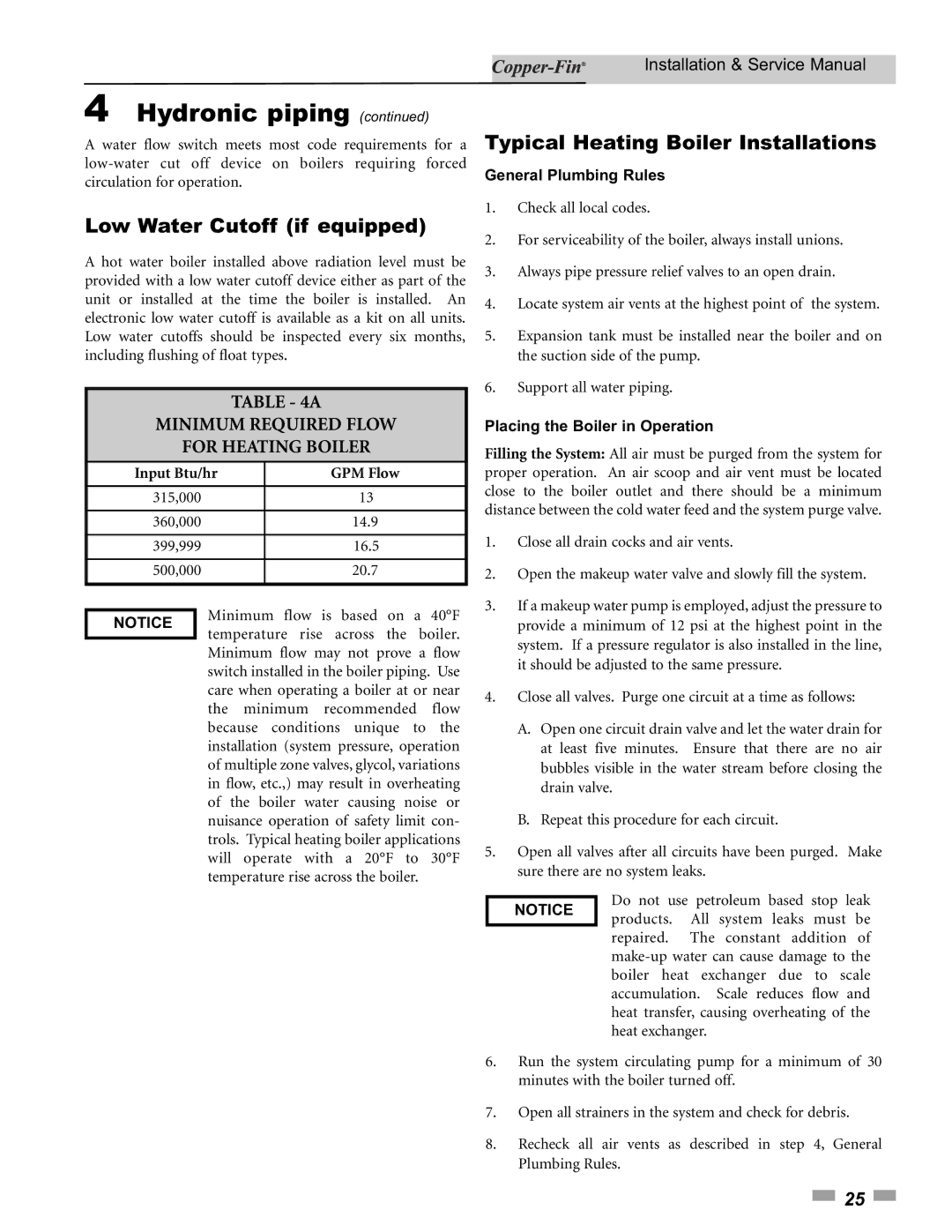

TABLE - 4A

MINIMUM REQUIRED FLOW

FOR HEATING BOILER

| Input Btu/hr | GPM Flow |

| ||

|

|

|

|

|

|

| 315,000 |

| 13 |

| |

|

|

|

|

|

|

| 360,000 |

| 14.9 |

| |

|

|

|

|

|

|

| 399,999 |

| 16.5 |

| |

|

|

|

|

|

|

| 500,000 |

| 20.7 |

| |

|

|

|

|

|

|

|

|

| Minimum flow is based on a 40°F |

| |

| NOTICE |

|

| ||

|

| temperature rise across the boiler. |

| ||

|

|

|

| ||

|

|

| Minimum flow may not prove a flow |

| |

|

|

| switch installed in the boiler piping. Use |

| |

|

|

| care when operating a boiler at or near |

| |

|

|

| the minimum recommended flow |

| |

|

|

| because conditions unique to the |

| |

|

|

| installation (system pressure, operation |

| |

|

|

| of multiple zone valves, glycol, variations |

| |

|

|

| in flow, etc.,) may result in overheating |

| |

|

|

| of the boiler water causing noise or |

| |

|

|

| nuisance operation of safety limit con- |

| |

|

|

| trols. Typical heating boiler applications |

| |

|

|

| will operate with a 20°F to 30°F |

| |

|

|

| temperature rise across the boiler. |

| |

Installation & Service Manual

Typical Heating Boiler Installations

General Plumbing Rules

1.Check all local codes.

2.For serviceability of the boiler, always install unions.

3.Always pipe pressure relief valves to an open drain.

4.Locate system air vents at the highest point of the system.

5.Expansion tank must be installed near the boiler and on the suction side of the pump.

6.Support all water piping.

Placing the Boiler in Operation

Filling the System: All air must be purged from the system for proper operation. An air scoop and air vent must be located close to the boiler outlet and there should be a minimum distance between the cold water feed and the system purge valve.

1.Close all drain cocks and air vents.

2.Open the makeup water valve and slowly fill the system.

3.If a makeup water pump is employed, adjust the pressure to provide a minimum of 12 psi at the highest point in the system. If a pressure regulator is also installed in the line, it should be adjusted to the same pressure.

4.Close all valves. Purge one circuit at a time as follows:

A.Open one circuit drain valve and let the water drain for at least five minutes. Ensure that there are no air bubbles visible in the water stream before closing the drain valve.

B.Repeat this procedure for each circuit.

5.Open all valves after all circuits have been purged. Make sure there are no system leaks.

NOTICE

Do not use petroleum based stop leak products. All system leaks must be repaired. The constant addition of

6.Run the system circulating pump for a minimum of 30 minutes with the boiler turned off.

7.Open all strainers in the system and check for debris.

8.Recheck all air vents as described in step 4, General Plumbing Rules.

![]() 25

25 ![]()