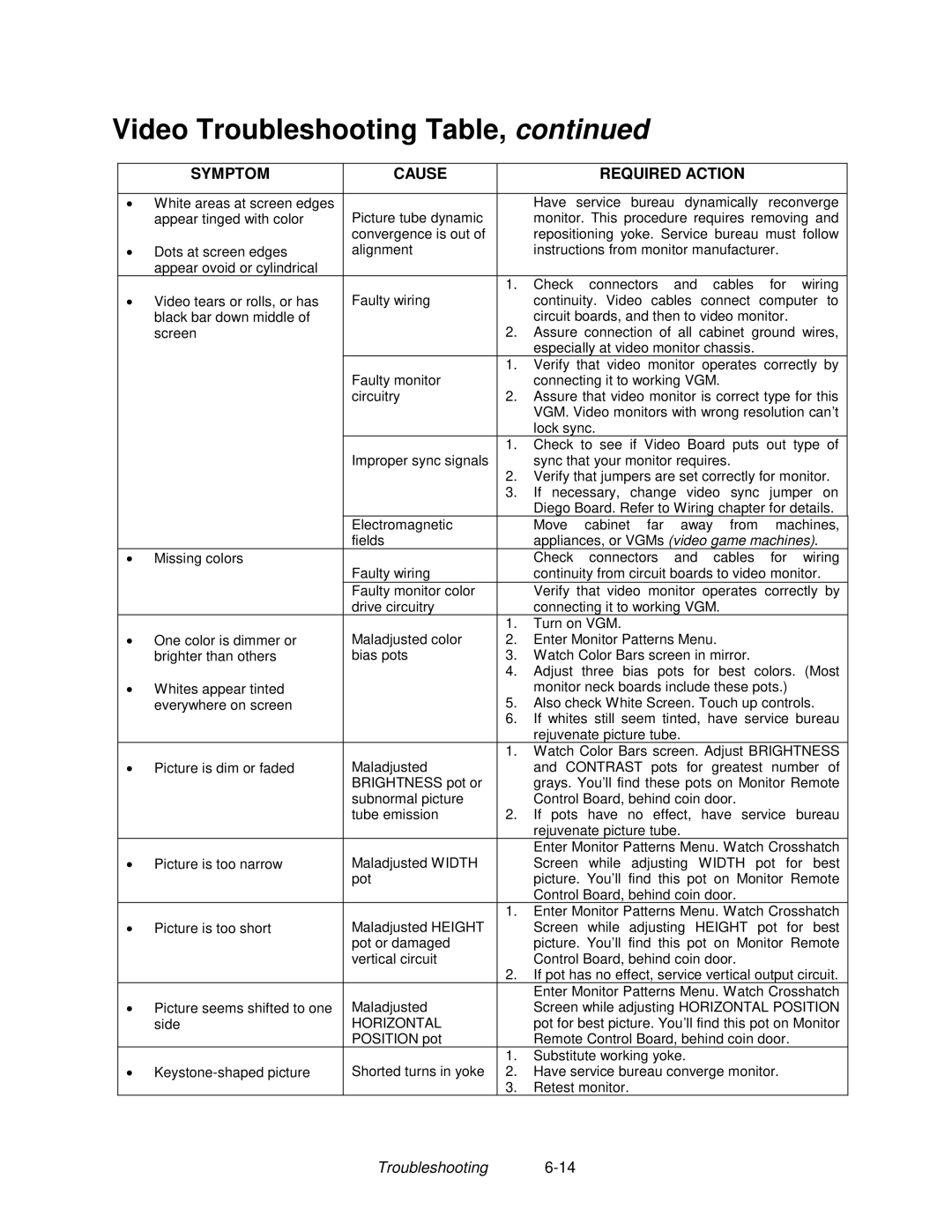

Video Troubleshooting Table, continued

| SYMPTOM | CAUSE |

| REQUIRED ACTION |

|

|

|

| |

• White areas at screen edges |

|

| Have service bureau dynamically reconverge | |

| appear tinged with color | Picture tube dynamic |

| monitor. This procedure requires removing and |

|

| convergence is out of |

| repositioning yoke. Service bureau must follow |

• Dots at screen edges | alignment |

| instructions from monitor manufacturer. | |

| appear ovoid or cylindrical |

|

|

|

|

|

| 1. | Check connectors and cables for wiring |

• Video tears or rolls, or has | Faulty wiring |

| continuity. Video cables connect computer to | |

| black bar down middle of |

|

| circuit boards, and then to video monitor. |

| screen |

| 2. | Assure connection of all cabinet ground wires, |

|

|

|

| especially at video monitor chassis. |

|

|

| 1. Verify that video monitor operates correctly by | |

|

| Faulty monitor |

| connecting it to working VGM. |

|

| circuitry | 2. | Assure that video monitor is correct type for this |

|

|

|

| VGM. Video monitors with wrong resolution can’t |

|

|

|

| lock sync. |

|

|

| 1. Check to see if Video Board puts out type of | |

|

| Improper sync signals |

| sync that your monitor requires. |

|

|

| 2. Verify that jumpers are set correctly for monitor. | |

|

|

| 3. If necessary, change video sync jumper on | |

|

|

|

| Diego Board. Refer to Wiring chapter for details. |

|

| Electromagnetic |

| Move cabinet far away from machines, |

|

| fields |

| appliances, or VGMs (video game machines). |

• | Missing colors |

|

| Check connectors and cables for wiring |

|

| Faulty wiring |

| continuity from circuit boards to video monitor. |

|

| Faulty monitor color |

| Verify that video monitor operates correctly by |

|

| drive circuitry |

| connecting it to working VGM. |

|

|

| 1. | Turn on VGM. |

• One color is dimmer or | Maladjusted color | 2. | Enter Monitor Patterns Menu. | |

| brighter than others | bias pots | 3. | Watch Color Bars screen in mirror. |

|

|

| 4. | Adjust three bias pots for best colors. (Most |

• | Whites appear tinted |

|

| monitor neck boards include these pots.) |

| everywhere on screen |

| 5. | Also check White Screen. Touch up controls. |

|

|

| 6. If whites still seem tinted, have service bureau | |

|

|

|

| rejuvenate picture tube. |

|

|

| 1. Watch Color Bars screen. Adjust BRIGHTNESS | |

• Picture is dim or faded | Maladjusted |

| and CONTRAST pots for greatest number of | |

|

| BRIGHTNESS pot or |

| grays. You’ll find these pots on Monitor Remote |

|

| subnormal picture |

| Control Board, behind coin door. |

|

| tube emission | 2. | If pots have no effect, have service bureau |

|

|

|

| rejuvenate picture tube. |

|

|

|

| Enter Monitor Patterns Menu. Watch Crosshatch |

• Picture is too narrow | Maladjusted WIDTH |

| Screen while adjusting WIDTH pot for best | |

|

| pot |

| picture. You’ll find this pot on Monitor Remote |

|

|

|

| Control Board, behind coin door. |

|

|

| 1. Enter Monitor Patterns Menu. Watch Crosshatch | |

• Picture is too short | Maladjusted HEIGHT |

| Screen while adjusting HEIGHT pot for best | |

|

| pot or damaged |

| picture. You’ll find this pot on Monitor Remote |

|

| vertical circuit |

| Control Board, behind coin door. |

|

|

| 2. If pot has no effect, service vertical output circuit. | |

|

|

|

| Enter Monitor Patterns Menu. Watch Crosshatch |

• Picture seems shifted to one | Maladjusted |

| Screen while adjusting HORIZONTAL POSITION | |

| side | HORIZONTAL |

| pot for best picture. You’ll find this pot on Monitor |

|

| POSITION pot |

| Remote Control Board, behind coin door. |

|

|

| 1. | Substitute working yoke. |

• | Shorted turns in yoke | 2. | Have service bureau converge monitor. | |

|

|

| 3. | Retest monitor. |

Troubleshooting