Using proper lifting equipment, lift the blender, using the lifting lugs attached to the top plate of the blender. These lifting lugs can also be used to fasten horizontal or angled braces to the blender if more stability is needed.

Note: Larger blenders need to be braced as part of the installation.

Take care to insure proper orientation with adequate access to operator controls, mix chamber, and metering units.

Note: Never weld on the blender, support stand, machine or mezzanine without first removing the control panel and verifying that the blender is properly grounded.

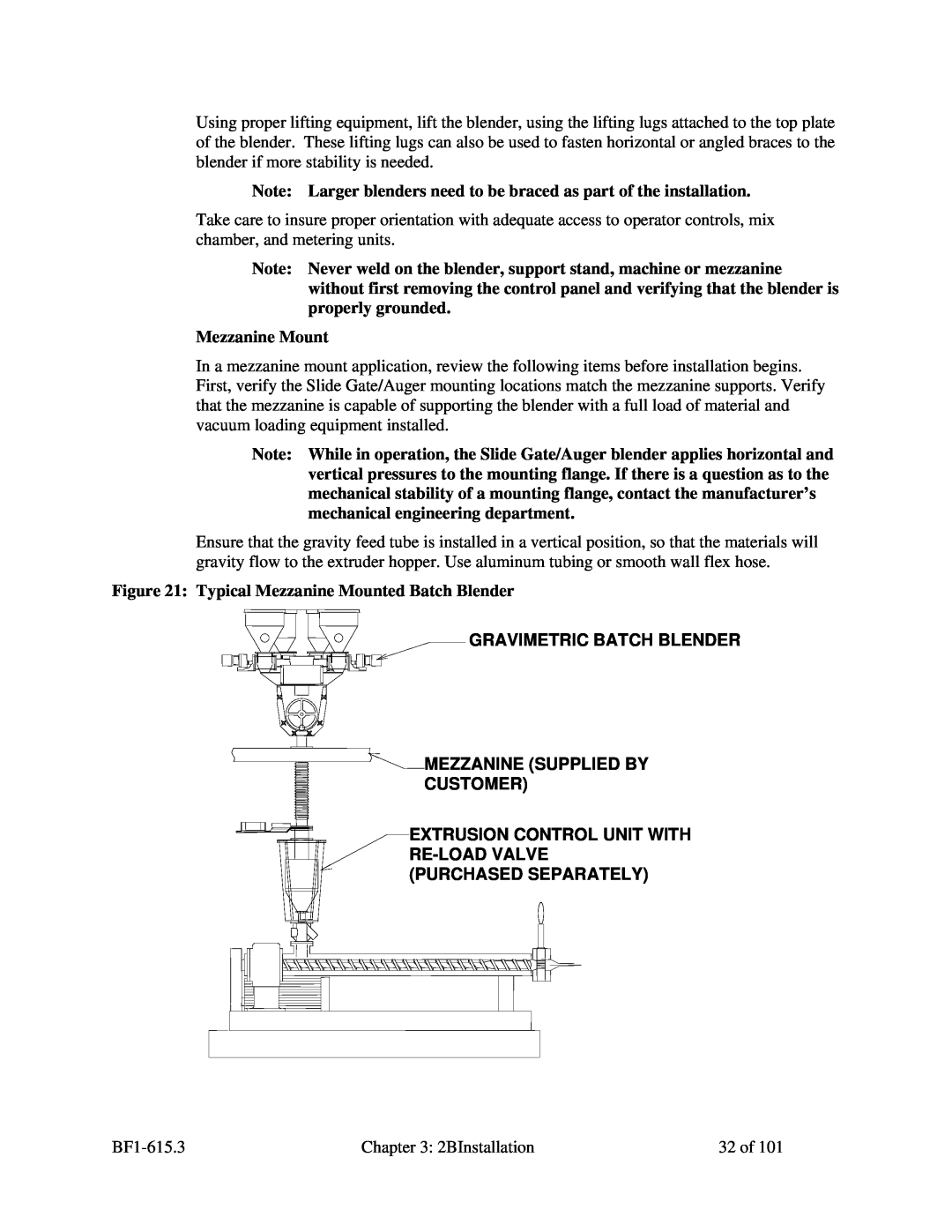

Mezzanine Mount

In a mezzanine mount application, review the following items before installation begins. First, verify the Slide Gate/Auger mounting locations match the mezzanine supports. Verify that the mezzanine is capable of supporting the blender with a full load of material and vacuum loading equipment installed.

Note: While in operation, the Slide Gate/Auger blender applies horizontal and vertical pressures to the mounting flange. If there is a question as to the mechanical stability of a mounting flange, contact the manufacturer’s mechanical engineering department.

Ensure that the gravity feed tube is installed in a vertical position, so that the materials will gravity flow to the extruder hopper. Use aluminum tubing or smooth wall flex hose.

Figure 21: Typical Mezzanine Mounted Batch Blender

GRAVIMETRIC BATCH BLENDER

![]() MEZZANINE (SUPPLIED BY

MEZZANINE (SUPPLIED BY

CUSTOMER)

EXTRUSION CONTROL UNIT WITH RE-LOAD VALVE (PURCHASED SEPARATELY)

Chapter 3: 2BInstallation | 32 of 101 |