If possible, use rigid tubing. Some flex hose will tend to sag and generate static that could cause

Make sure that adequate space is around the blender (36” recommended) to allow proper cleaning, servicing, etc.

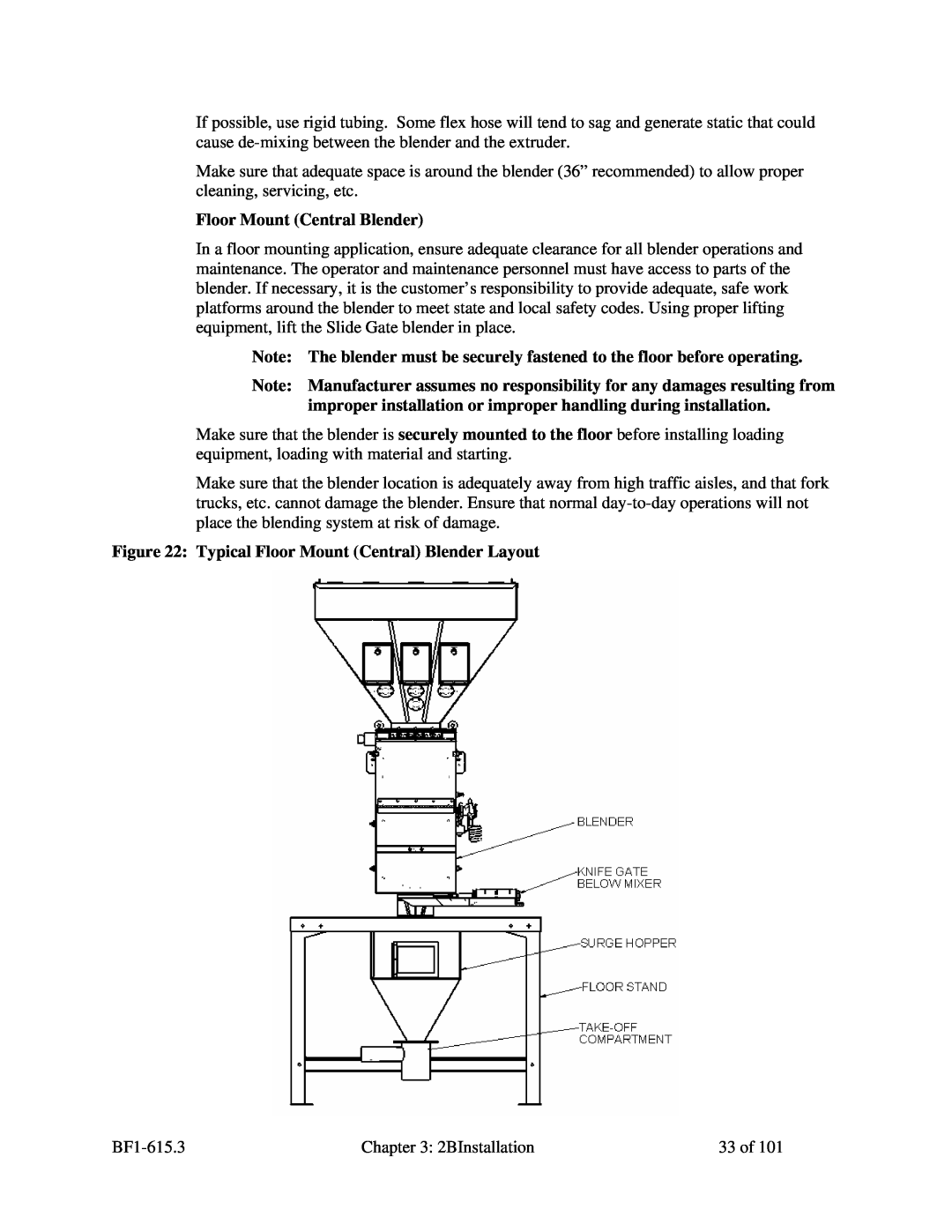

Floor Mount (Central Blender)

In a floor mounting application, ensure adequate clearance for all blender operations and maintenance. The operator and maintenance personnel must have access to parts of the blender. If necessary, it is the customer’s responsibility to provide adequate, safe work platforms around the blender to meet state and local safety codes. Using proper lifting equipment, lift the Slide Gate blender in place.

Note: The blender must be securely fastened to the floor before operating.

Note: Manufacturer assumes no responsibility for any damages resulting from improper installation or improper handling during installation.

Make sure that the blender is securely mounted to the floor before installing loading equipment, loading with material and starting.

Make sure that the blender location is adequately away from high traffic aisles, and that fork trucks, etc. cannot damage the blender. Ensure that normal

Figure 22: Typical Floor Mount (Central) Blender Layout

Chapter 3: 2BInstallation | 33 of 101 |