ENGLISH

10.4. Oil balance pipe connection method

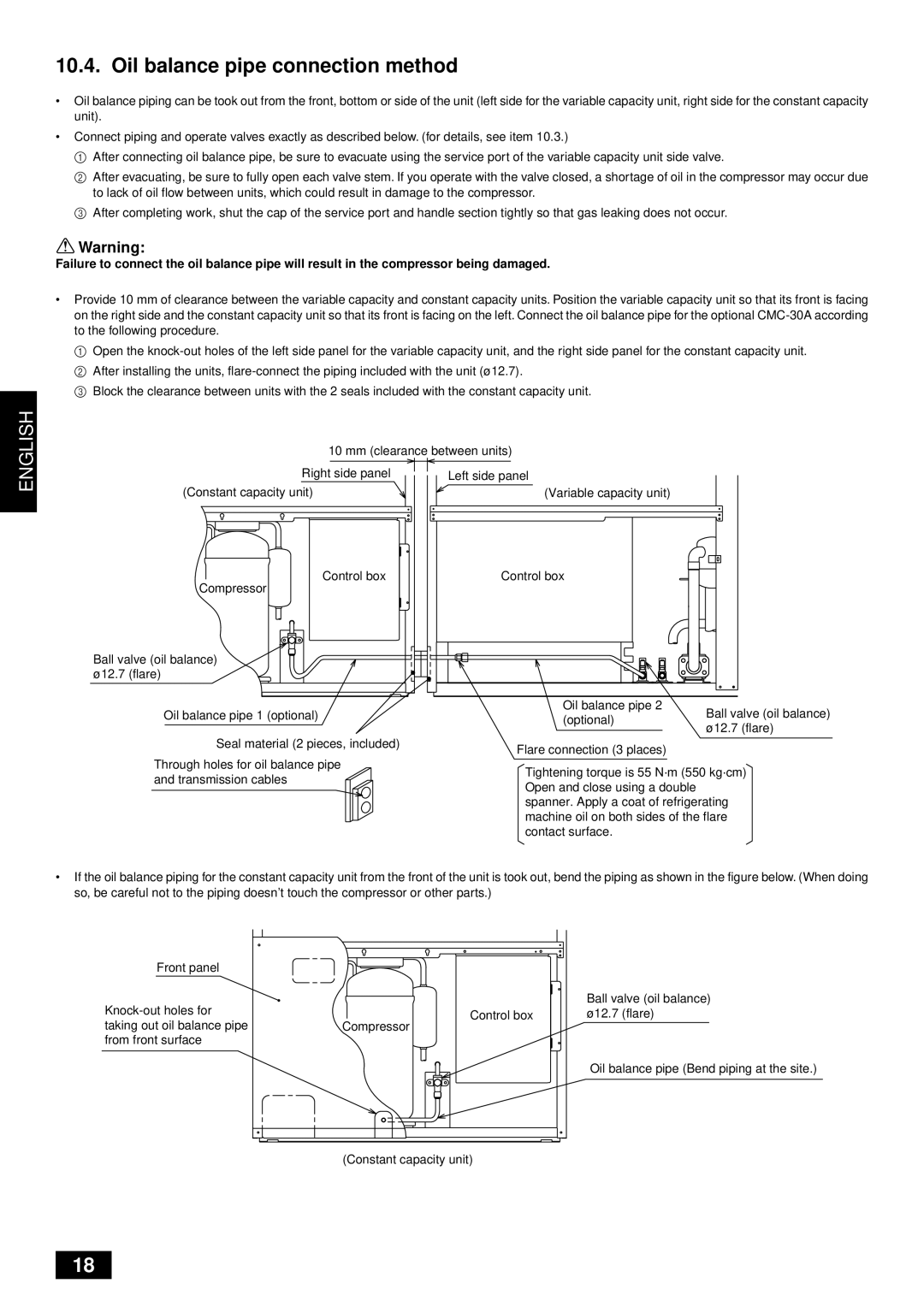

•Oil balance piping can be took out from the front, bottom or side of the unit (left side for the variable capacity unit, right side for the constant capacity unit).

•Connect piping and operate valves exactly as described below. (for details, see item 10.3.)

1 After connecting oil balance pipe, be sure to evacuate using the service port of the variable capacity unit side valve.

2 After evacuating, be sure to fully open each valve stem. If you operate with the valve closed, a shortage of oil in the compressor may occur due to lack of oil flow between units, which could result in damage to the compressor.

3 After completing work, shut the cap of the service port and handle section tightly so that gas leaking does not occur.

![]() Warning:

Warning:

Failure to connect the oil balance pipe will result in the compressor being damaged.

•Provide 10 mm of clearance between the variable capacity and constant capacity units. Position the variable capacity unit so that its front is facing on the right side and the constant capacity unit so that its front is facing on the left. Connect the oil balance pipe for the optional

1 Open the

2 After installing the units,

3 Block the clearance between units with the 2 seals included with the constant capacity unit.

10 mm (clearance between units)

Right side panel | Left side panel |

(Constant capacity unit) | (Variable capacity unit) |

Control box

Compressor

Ball valve (oil balance) ø 12.7 (flare)

Oil balance pipe 1 (optional)

Seal material (2 pieces, included)

Through holes for oil balance pipe and transmission cables

Control box

Oil balance pipe 2

(optional)Ball valve (oil balance) ø 12.7 (flare)

Flare connection (3 places)

Tightening torque is 55 N·m (550 kg·cm) Open and close using a double spanner. Apply a coat of refrigerating machine oil on both sides of the flare contact surface.

•If the oil balance piping for the constant capacity unit from the front of the unit is took out, bend the piping as shown in the figure below. (When doing so, be careful not to the piping doesn’t touch the compressor or other parts.)

Front panel |

|

|

| Ball valve (oil balance) | |

Control box | ø 12.7 (flare) | |

taking out oil balance pipe | Compressor |

|

from front surface |

|

|

|

| Oil balance pipe (Bend piping at the site.) |

(Constant capacity unit)

18